Load-shedding sound barrier unit board

A technology of unit panels and sound barriers, applied in construction, noise absorption devices, etc., can solve problems such as driving safety threats, affecting driving safety, and damage to sound barriers, and achieve the effects of beautifying the environment, reducing damage, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

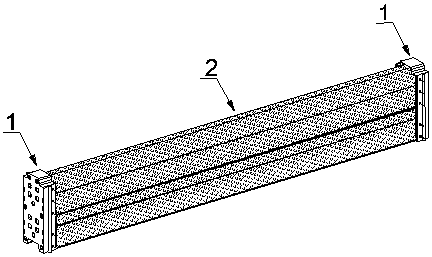

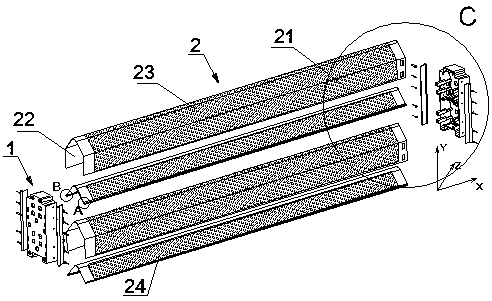

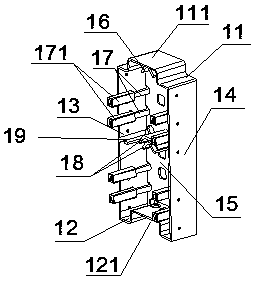

[0025] Such as figure 1 with figure 2 As shown, the embodiment of the present invention provides a load-reducing type sound barrier unit board, which includes at least one unit board body 2 and the load-reducing type sound barriers which are arranged at two ends of the unit board body 2 and are adjacent to each other up and down. Lapping part 1 where the unit plates overlap each other. The unit board body 2 is a hollow shell formed by the sound-absorbing wall 21, the upper wall 23, the sound-insulating wall 22 and the lower wall 24, which are fixed head-to-tail and connected in turn. The upper wall 23 and the lower wall 24 are curved structures, overlapping The component 1 is a housing with an open end, and the two ends of the unit board body 2 are respectively inserted into the corresponding overlapping component 1 from the open ends. The unit boa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com