Split assembly and disassembly type device for measuring automobile four-wheel aligner

A technology of four-wheel aligner and verification device, which is applied in the direction of wheel testing, etc., and can solve the problems of large volume, time-consuming equipment leveling, inconvenient transportation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The present invention is described in detail below in conjunction with accompanying drawing:

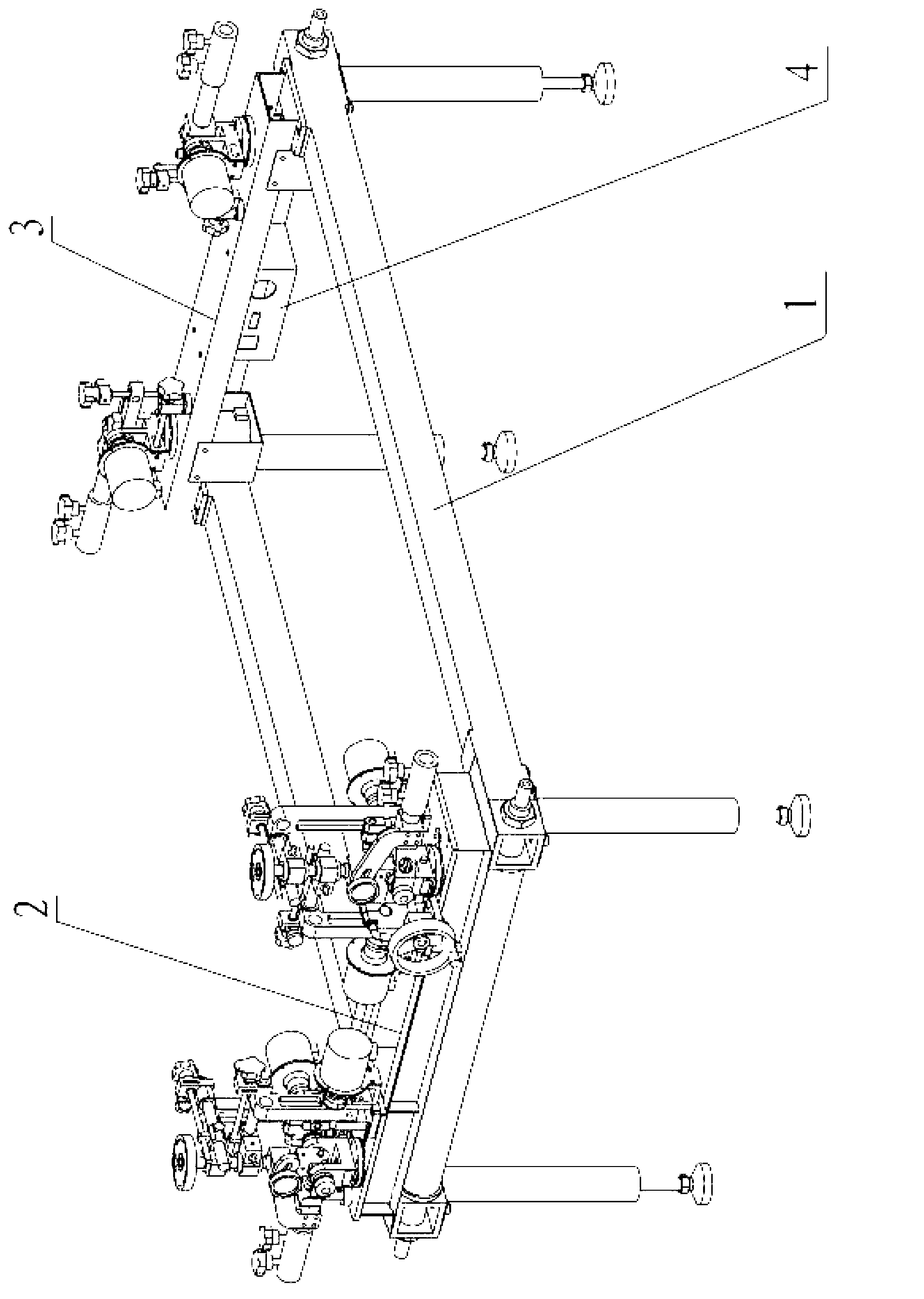

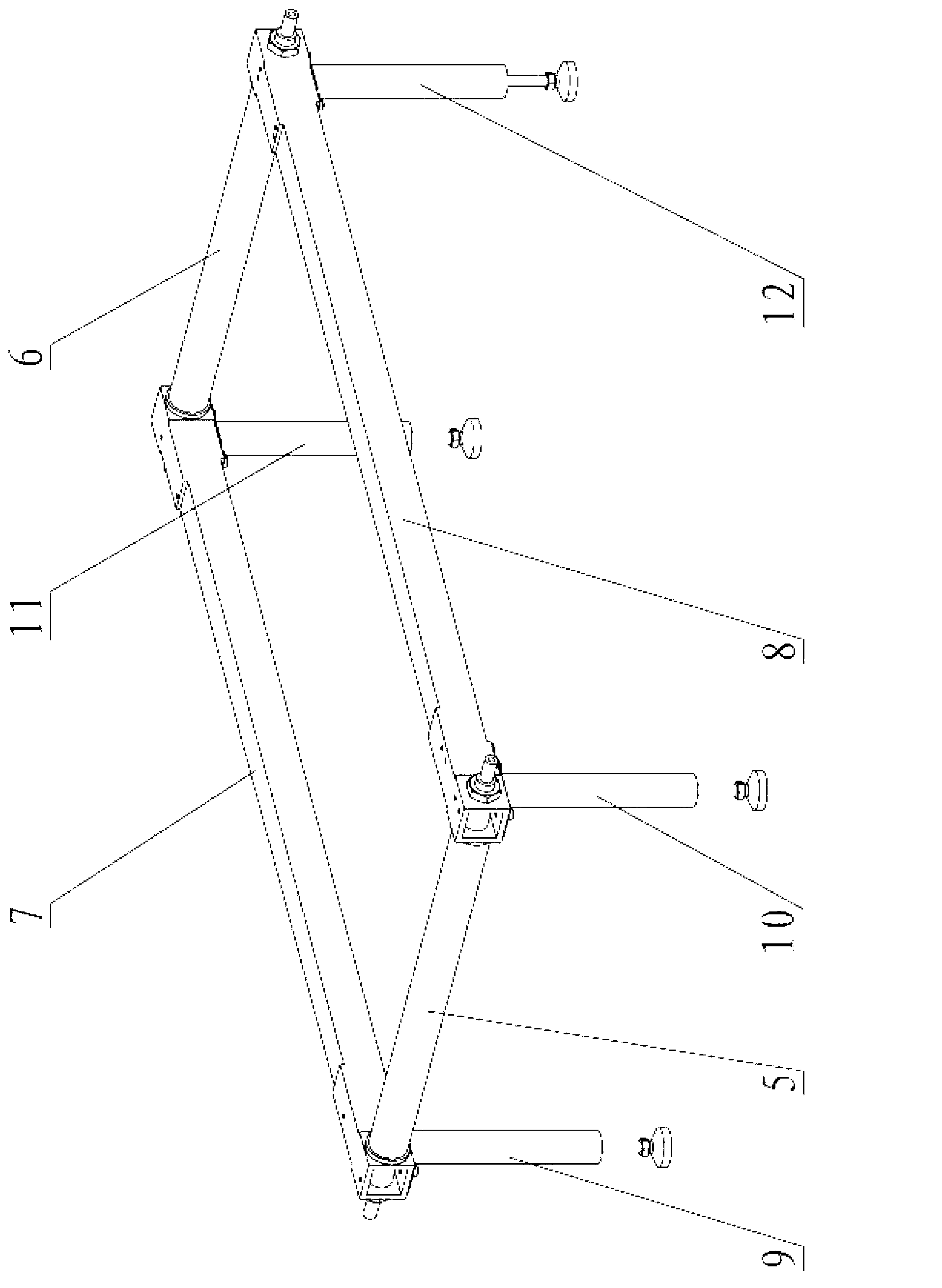

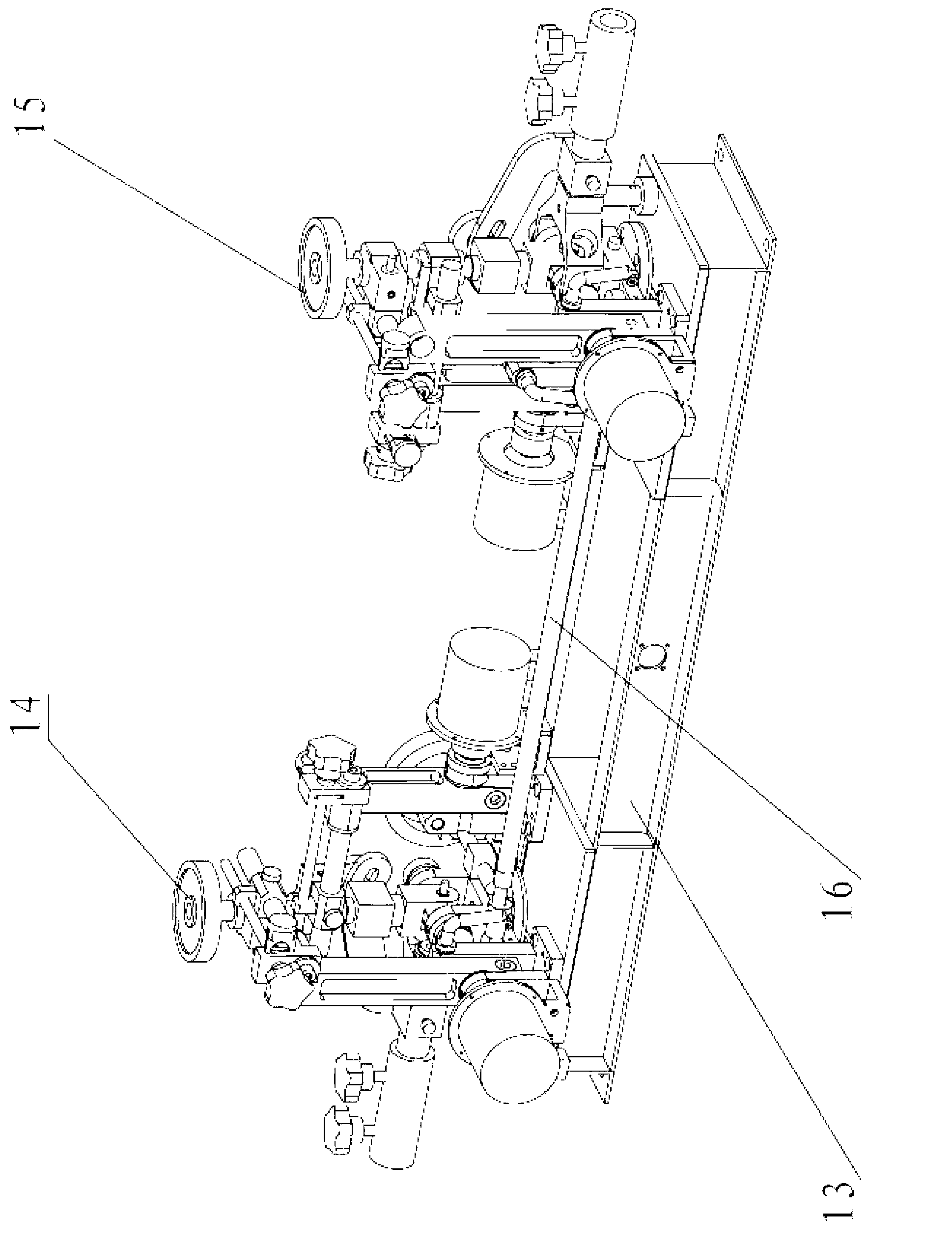

[0085] refer to figure 1 The difference between the detachable and detachable four-wheel alignment device of the present invention and the prior art is that its overall structure adopts a detachable and detachable type, mainly consisting of a toe-in zero-point inspection frame 1 and a front frame inspection part 2. , The background frame inspection part 3 and the circuit box 4 are composed. The toe-in zero-point inspection frame 1 is used as the installation base of the front-end frame inspection part 2 and the back-end frame inspection part 3 to complete the inspection of the toe-in zero point of the four-wheel aligner; the front-end frame inspection part 2 is installed on the toe-in zero-point inspection frame 1 The left longitudinal beam 7 and the right longitudinal beam 8 are fixedly connected by bolts on the front mounting platform, and the test of the kingpin caster ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com