Array substrate, manufacturing method thereof, and display device

An array substrate and manufacturing method technology, applied in the field of liquid crystal display, can solve problems such as large contact resistance and uneven charge distribution, and achieve the effect of uniform charge distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

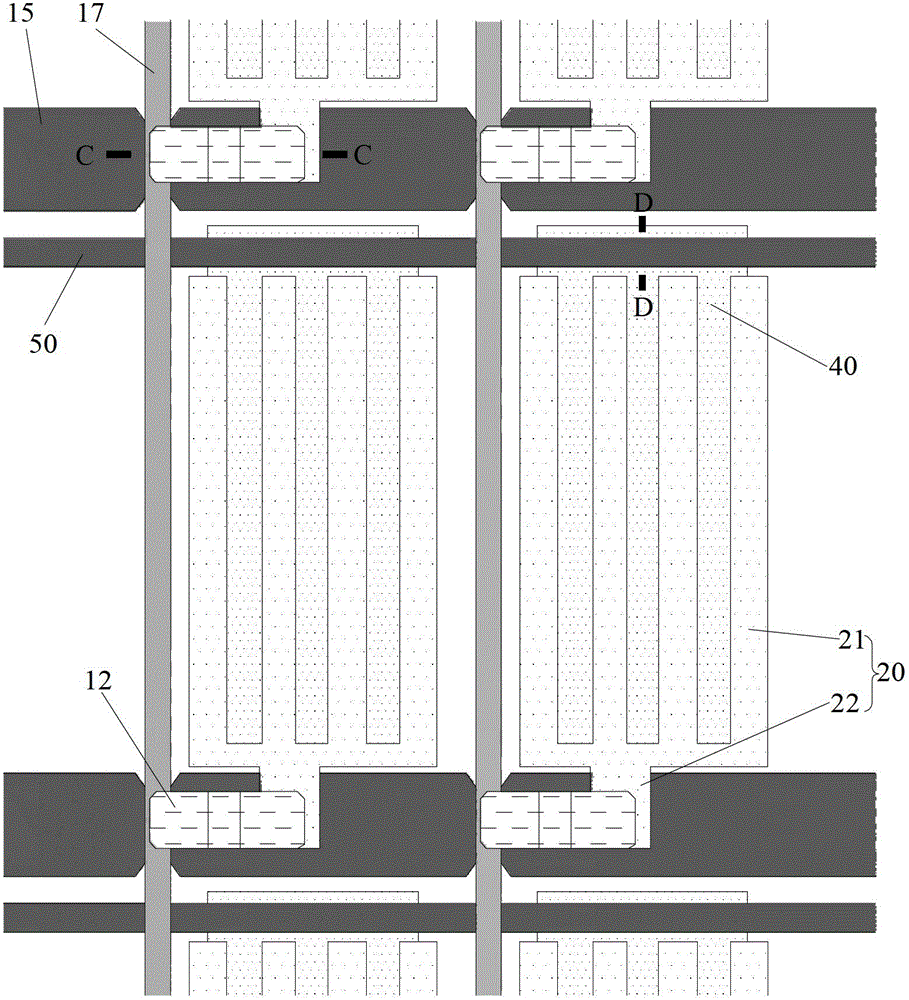

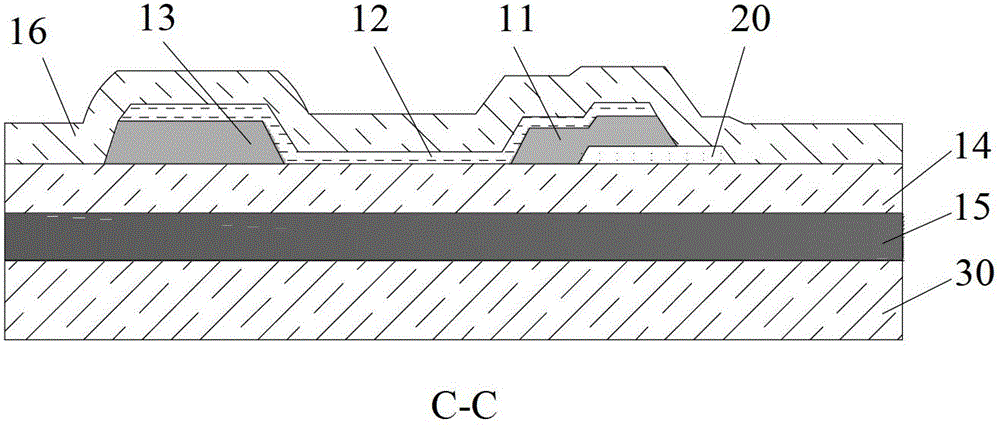

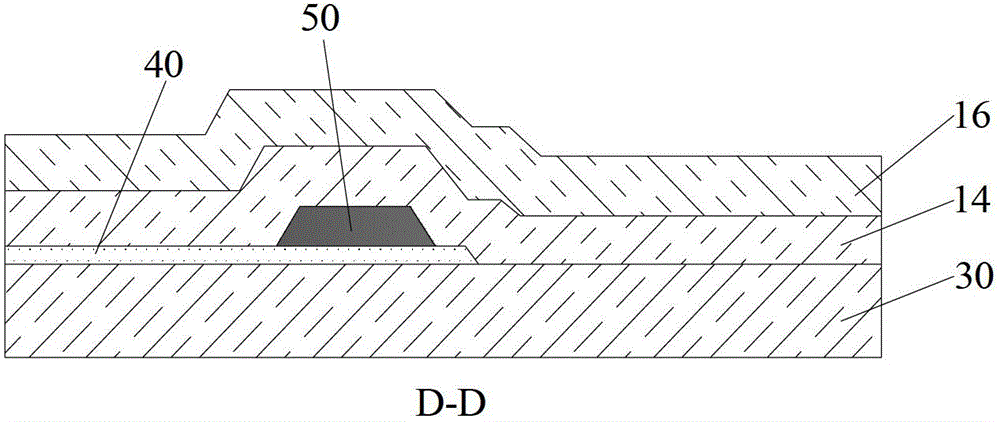

[0066] As the first embodiment of the present invention, such as figure 1 with figure 2 As shown, the pixel electrode 20 may include a pixel electrode body 21 and a connecting portion 22 protruding from the pixel electrode body 21. The connecting portion 22 is disposed between the drain electrode 11 of the thin film transistor and the gate insulating layer 14 of the thin film transistor. between. able to pass Figure 8 The processing steps shown in FIG. 2 form the pixel electrode 20 in this manner. Hereinafter, the manufacturing method of the array substrate described in the first embodiment will be introduced in detail, which will not be repeated here.

[0067] As the second embodiment of the present invention, such as Picture 9 with Picture 10 As shown, the pixel electrode 20 includes a pixel electrode body 21 and a connecting portion 22 protruding from the pixel electrode body 21, and the connecting portion 22 covers a part of the upper surface of the drain electrode 11 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com