Industrial field equipment energy efficiency evaluation method

A technology for industrial field equipment and equipment efficiency, applied in the fields of energy technology and electrical engineering, can solve problems such as online energy efficiency calculation of industrial field equipment, and achieve the effects of reducing electricity costs, ensuring accuracy, and optimizing electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The present invention will be further described below in conjunction with the accompanying drawings.

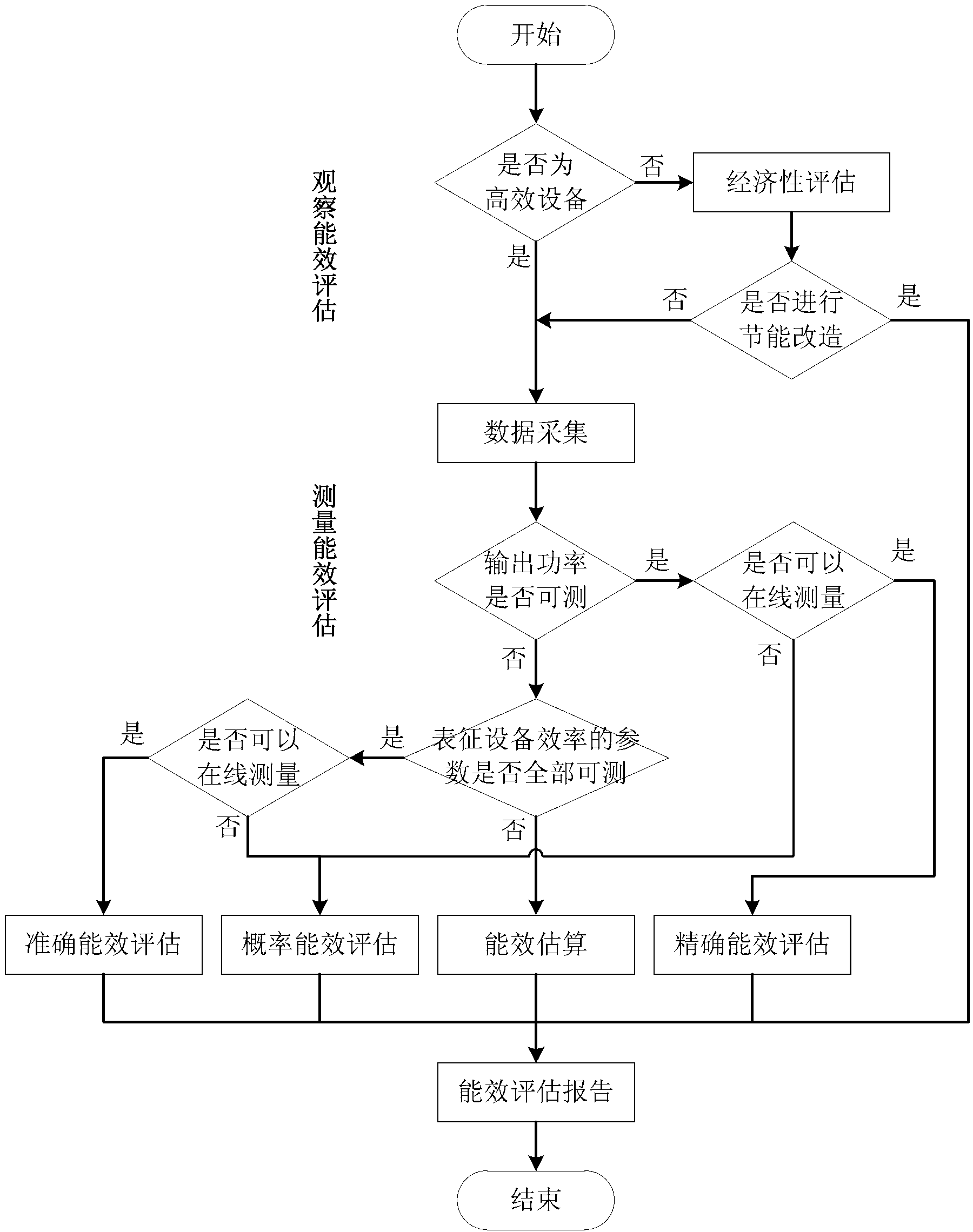

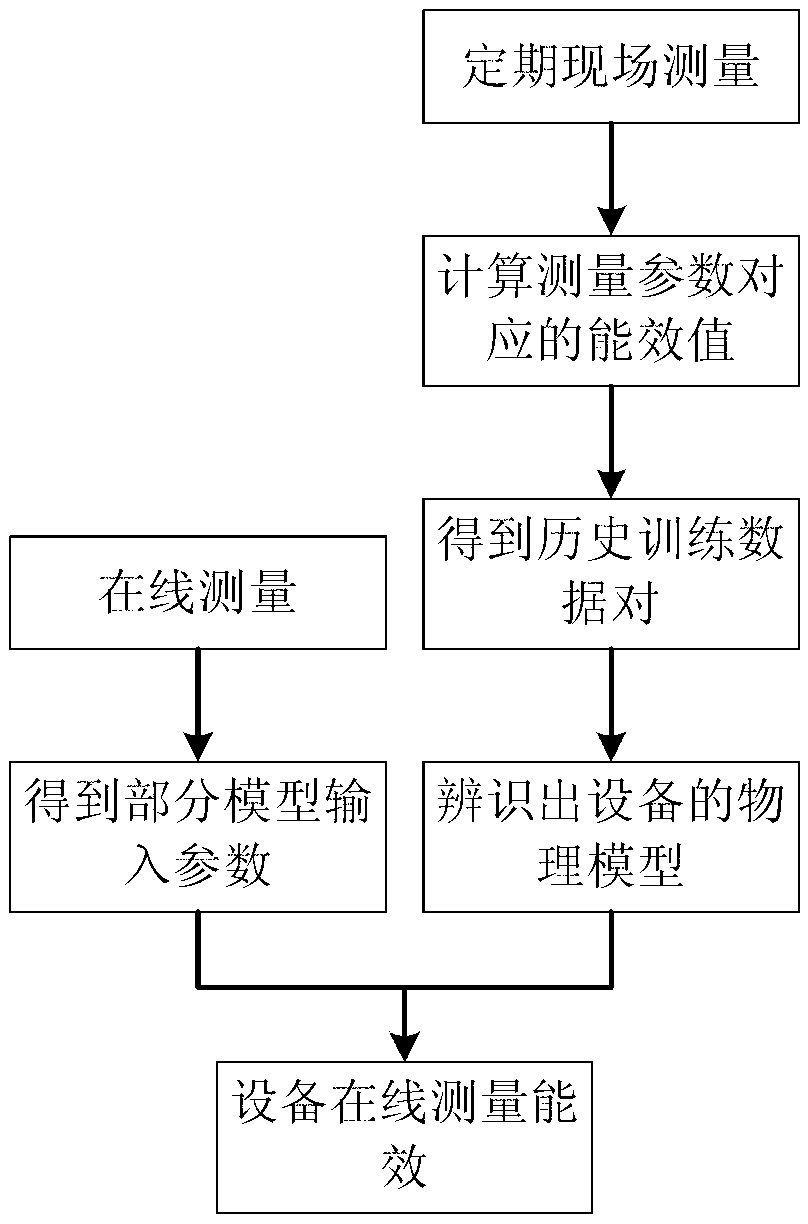

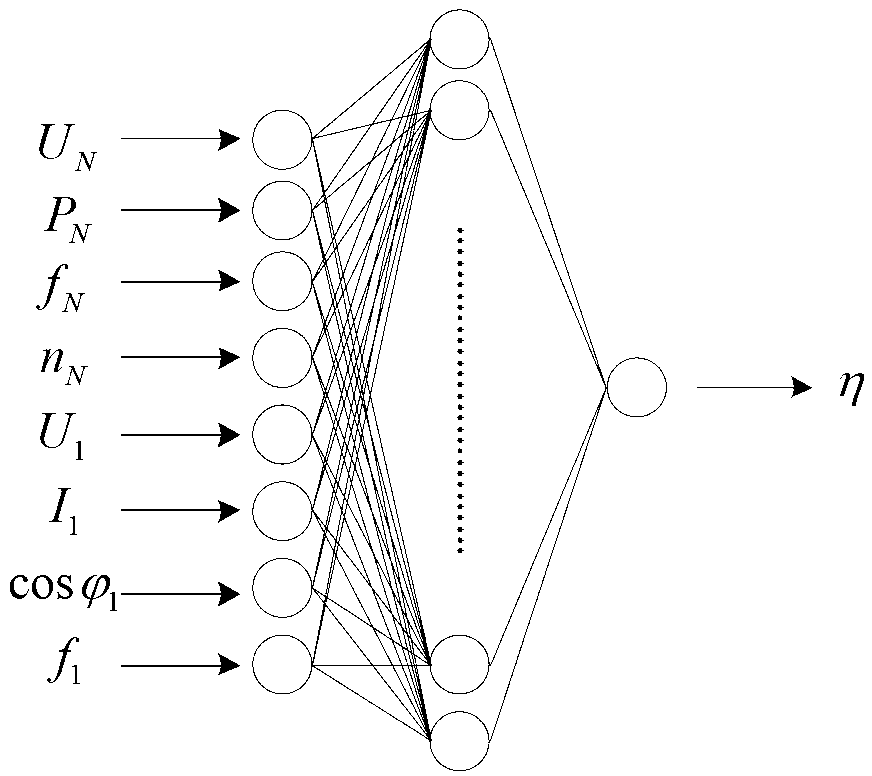

[0033] An energy efficiency evaluation method for industrial field equipment, which uses the artificial neural network-based probabilistic energy efficiency evaluation method for the evaluation of the energy efficiency of three-phase asynchronous motors with limited industrial field parameter measurement, as follows.

[0034] (1) Observing energy efficiency: check the equipment nameplate, according to the equipment model and factory rated power η N , check the national standard energy efficiency limit value and energy efficiency grade standard of this type of equipment, and judge whether the equipment belongs to the high-efficiency equipment stipulated by the state; conduct economic evaluation of energy-saving transformation and replacement transformation of non-efficient equipment.

[0035] For example: the nameplate parameters of the three-phase asynchronous motor are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com