Special single-beat welding machine for steel bar trusses

A steel truss and welding machine technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of unstable welding quality, high cost, complex structure, etc., to reduce labor intensity and production cost, and achieve a high degree of automation. , the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

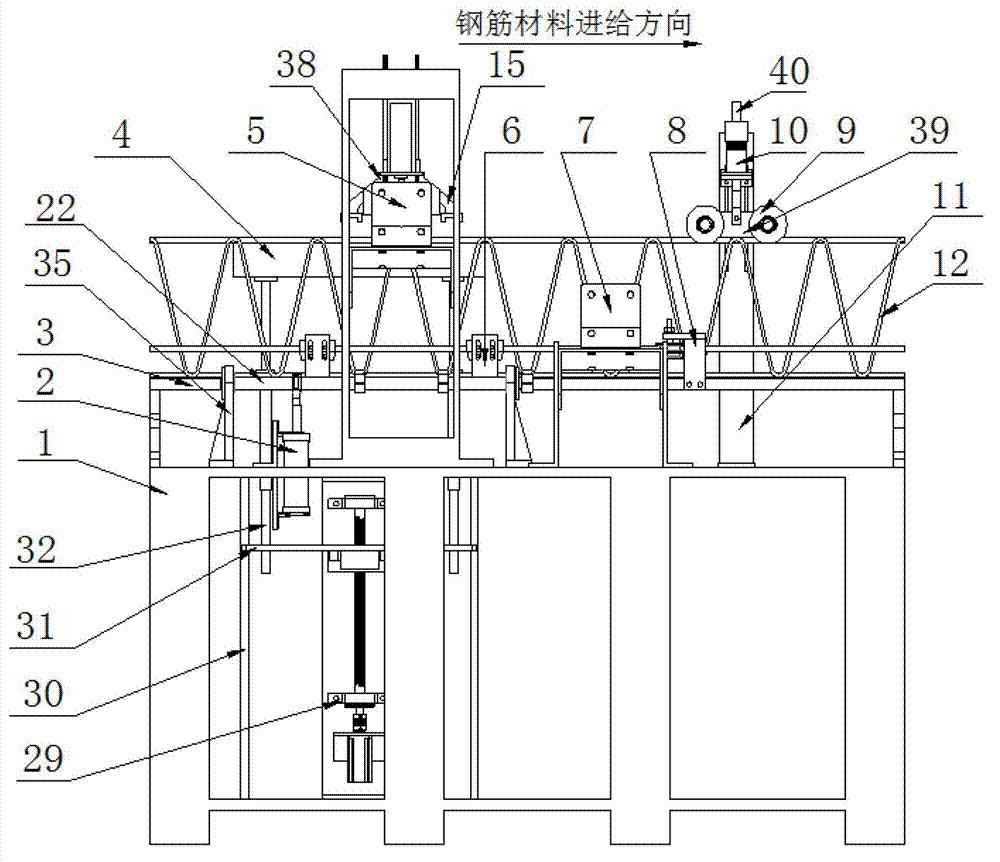

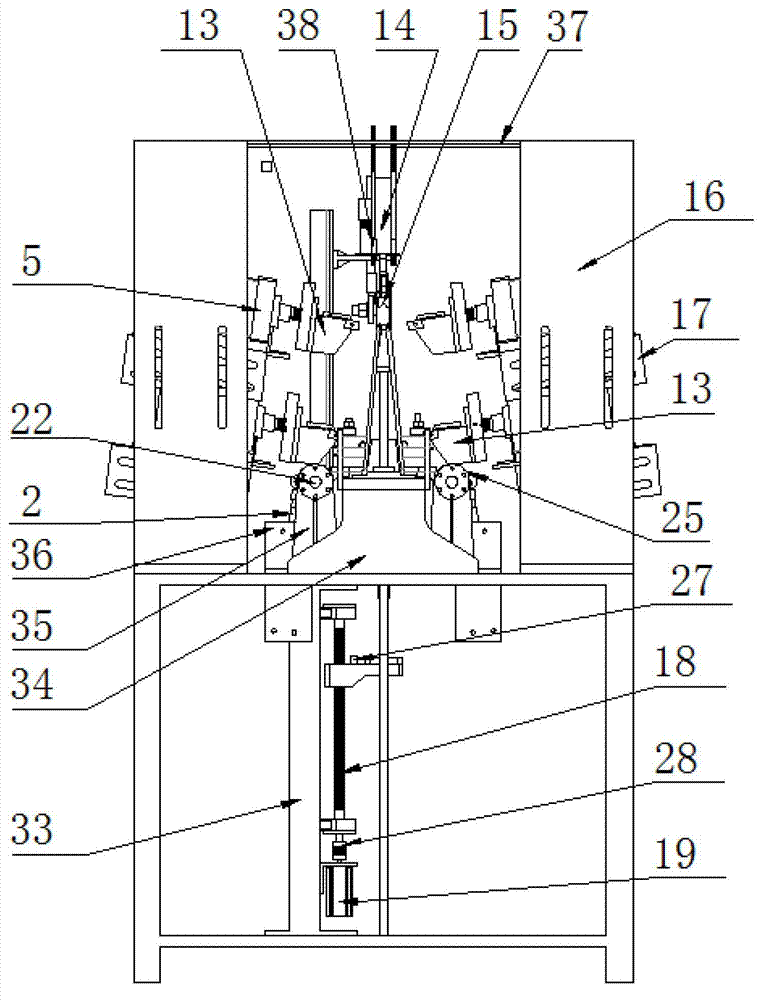

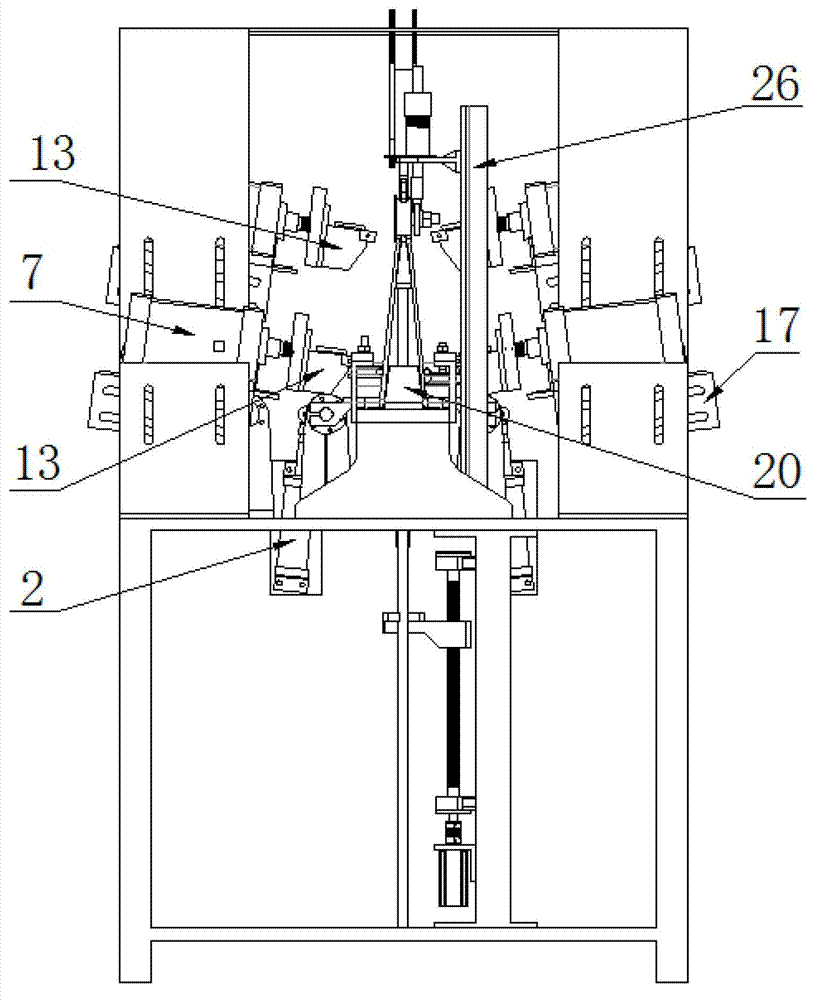

[0016] combine figure 1 , Figure 4 , a special welding machine for a single-beat steel bar truss of the present invention, comprising a machine base 1, a workbench 3, an automatic height-adjustable upper chord bar support frame 4, a lower chord bar positioning mechanism 6, a web bar steel bar positioning and pressing mechanism 25, an upper welding Device 24, lower welding device 23, positioning and guiding device 8 under the steel bar truss, and positioning and guiding device 26 on the steel bar truss; the welding machine is divided into a front working part and a rear working part according to the feeding direction of the steel bar material, and the upper middle part of the machine base 1 is set Workbench 3, the upper chord bar support frame 4 that can be automatically adjusted is set above the workbench 3 of the front work part, the lower chord bar positioning mechanism 6 is symmetrically distributed on both sides of the workbench 3 of the front work part, and the positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com