Truck fuel tank

A technology for fuel tanks and trucks, applied in the field of truck manufacturing, can solve problems such as waste of remaining fuel in the fuel tank and engine stall, and achieve the effects of reducing potential safety hazards, improving service life, and achieving fluency and installation convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

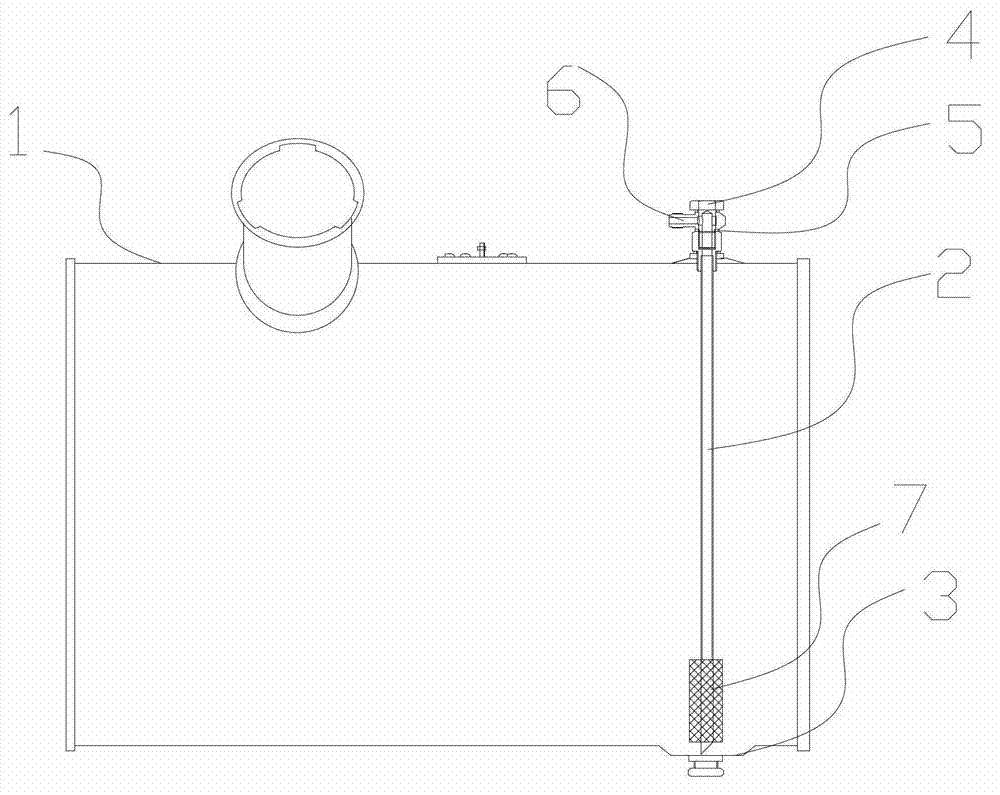

[0025] The present invention will be further explained below in conjunction with the drawings.

[0026] Such as figure 1 As shown, a fuel tank for a truck includes a fuel tank 1 and a fuel suction pipe 2. The fuel suction pipe 2 is arranged inside the fuel tank 1, and the bottom of the fuel tank 1 is provided with at least one groove 3, the groove 3 The number provided is the same as the number of the oil suction pipe 2. The two ends of the oil suction pipe 2 are the oil suction end and the oil discharge end respectively. The oil suction end extends out of the bottom plane of the fuel tank 1 and is arranged in the groove 3. The oil outlet extends out of the upper part of the fuel tank 1 and the oil outlet is provided with an articulated bolt joint 4, the articulated bolt joint 4 can rotate freely, and the number of the articulated bolt joints 4 is the same as that of the oil suction pipe 2. . In addition, the oil suction pipe 2 is hermetically connected to the fuel tank 1 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com