Lock-stopping hinge assembly and sound apparatus using same to realize lower-flicking mode

A hinge assembly and locking technology, applied to the support structure, electrical components, door/window accessories, etc. on the hinge/pivot, can solve the problems of cumbersome assembly, inability to proceed smoothly, and increased parts and components, and reduce the number of components. , The pop-up operation is smooth, and the effect of simplifying the sound assembly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

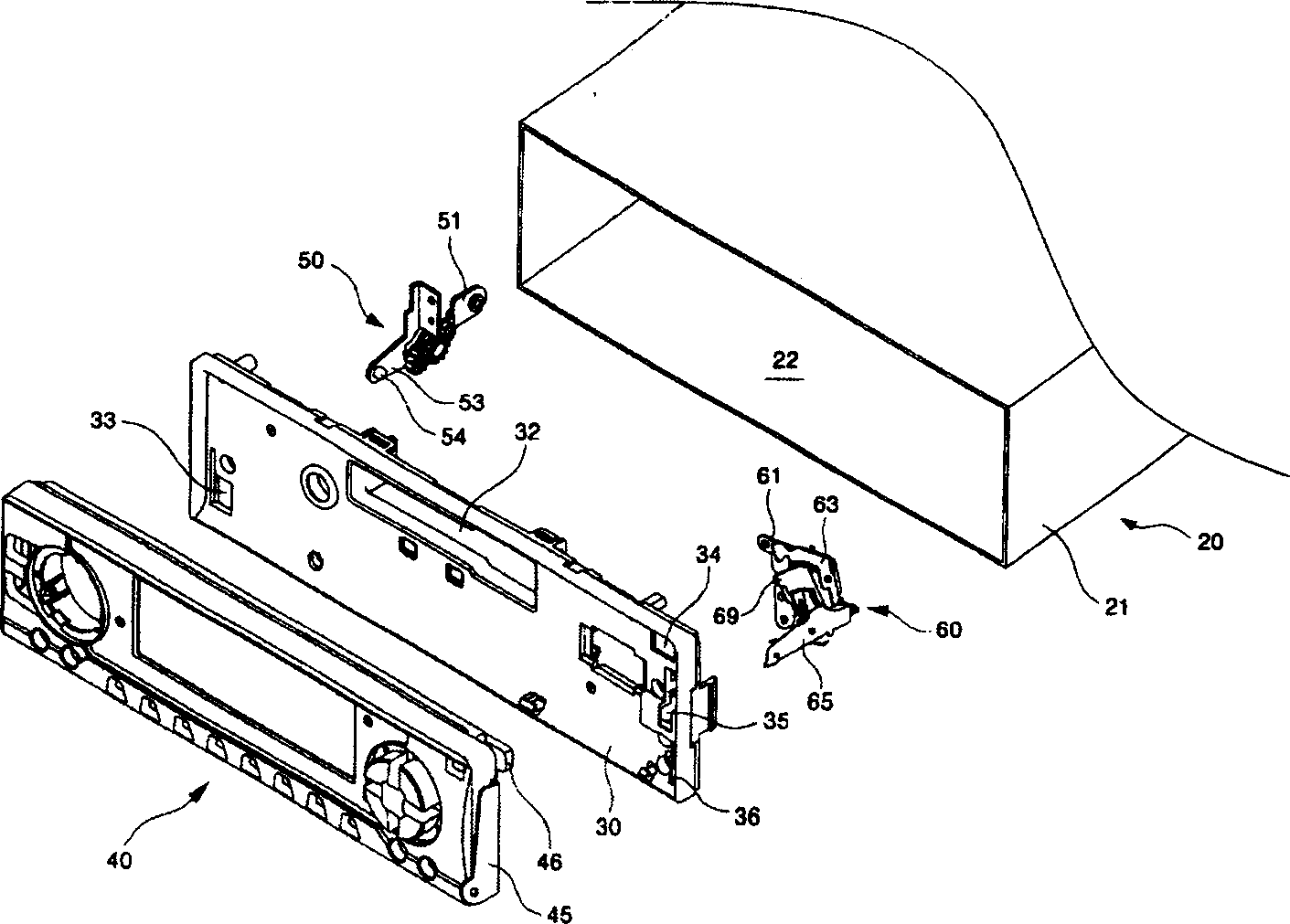

[0042] The locking hinge assembly of the present invention and the ideal embodiment of the audio device using the locking hinge assembly to realize the pop-up mode will be described in detail below with reference to the accompanying drawings.

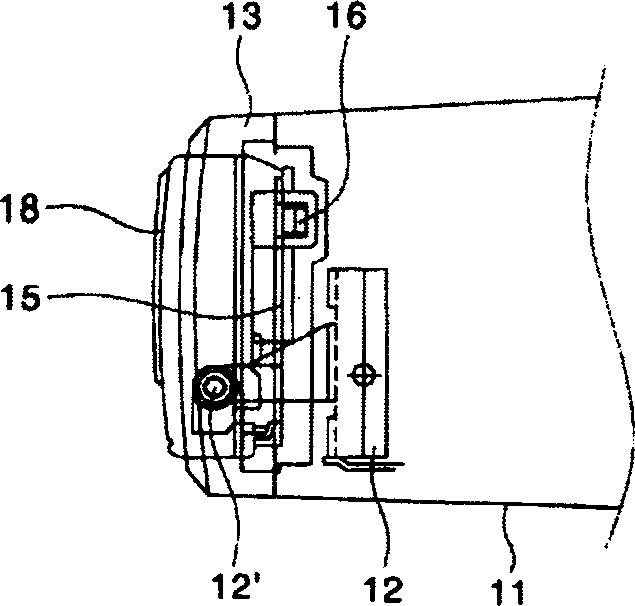

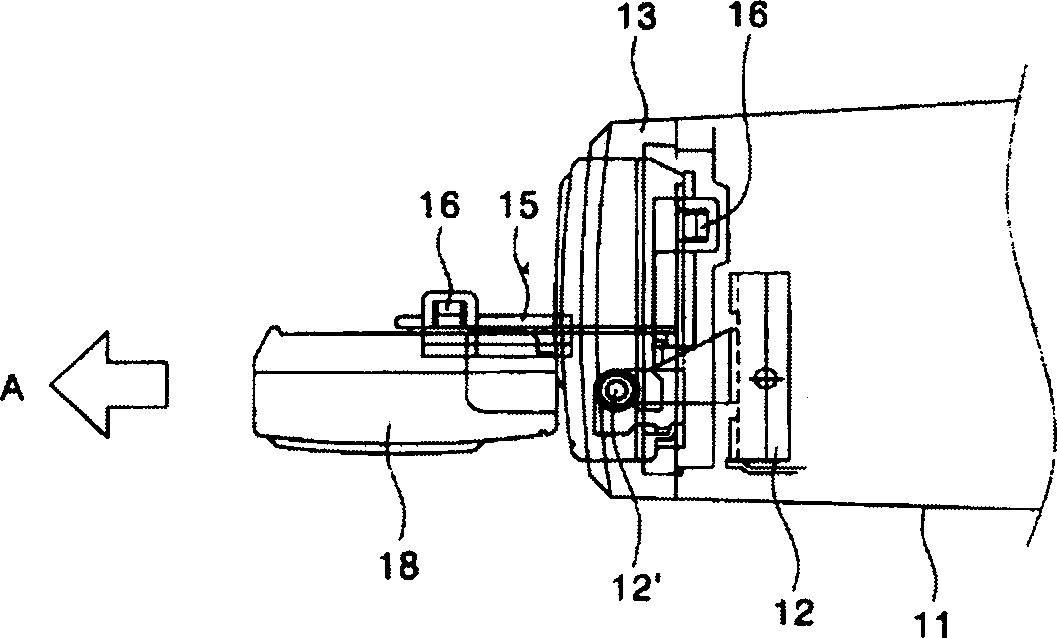

[0043] image 3 It is a schematic diagram for disassembling and explaining the configuration of an ideal embodiment of a pop-down type acoustic device using a locking hinge assembly. Figure 4 It is a schematic diagram of the composition of the locking hinge assembly in the embodiment of the present invention. Figure 5 It is an exploded schematic view of the structure of the locking hinge assembly in the embodiment of the present invention.

[0044] As shown in the figure, what constitutes the exterior of the main body portion 20 is a case 21. The case 21 is a hexahedron with an open front. The interior of the case 21 is an internal space 22 for arranging various components (not shown).

[0045] A switch plate 30 is provided at the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com