Laterally packaging mechanism of soft tissue packaging machine

A paper bag and soft pumping technology, applied in the field of improved invention, can solve the problems of low production efficiency, complicated structure of side sealing mechanism, etc., and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

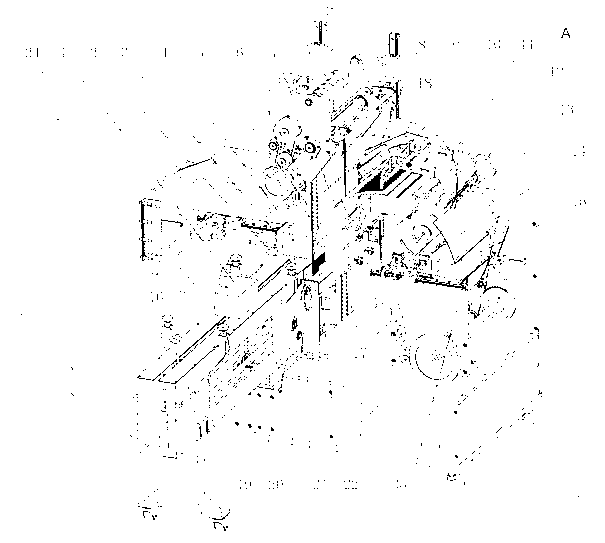

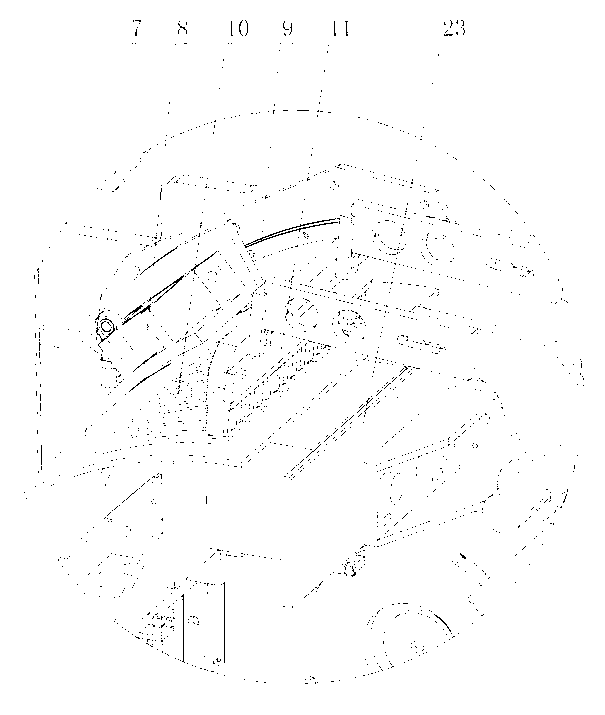

[0017] Referring to the accompanying drawings, the side sealing mechanism of this kind of soft paper packaging machine includes a frame 24 and a turntable 32, the turntable 32 is connected to a power source, and the power source can use a cylinder or a motor to drive the turntable 32 to rotate; along the turntable 32 Circumferential direction is provided with packaging station 25, heat-sealing station 26 and discharge station 27 successively, described turntable 32 is evenly distributed with fixture 23 along the circumferential direction, and described fixture 23 is four pairs in the present embodiment, divides Up, down, left and right; the packaging station 25, heat sealing station 26 and discharge station 27 correspond to the clamp 23 on the turntable respectively, and the clamp 23 includes a first splint 28, a second Clamping plate 29 and slide rail 31, described second clamping plate 29 is installed on the slide rail by clamping plate seat 30, and described clamping plate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com