Ring Pipeline

An assembly line and annular technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of low labor efficiency, cumbersome, and many processing steps, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

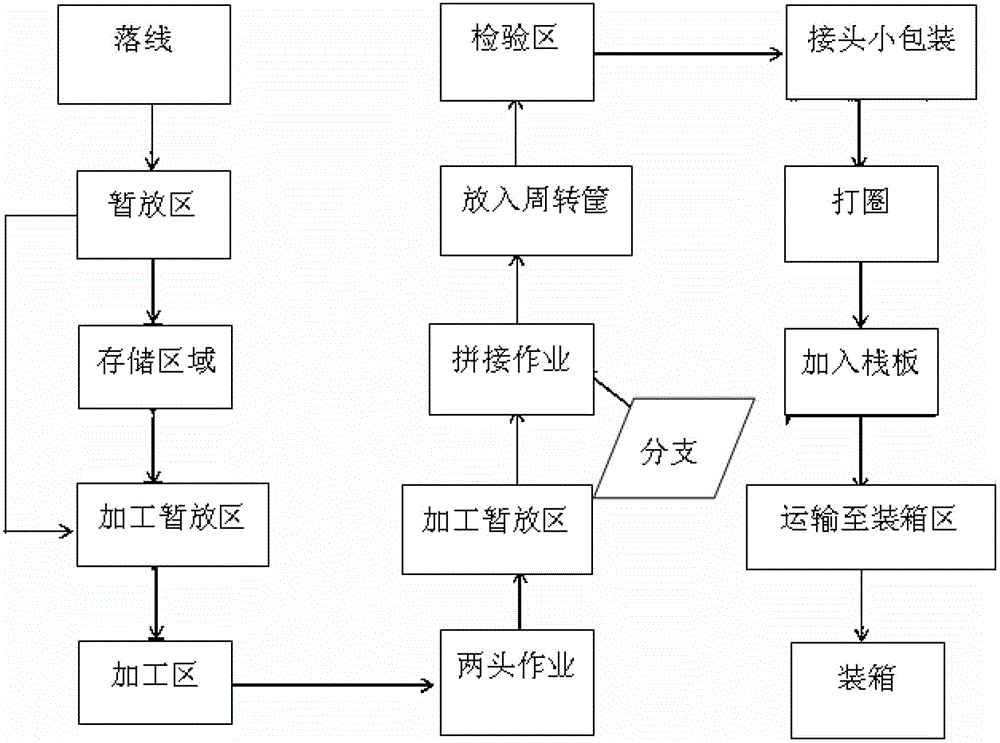

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

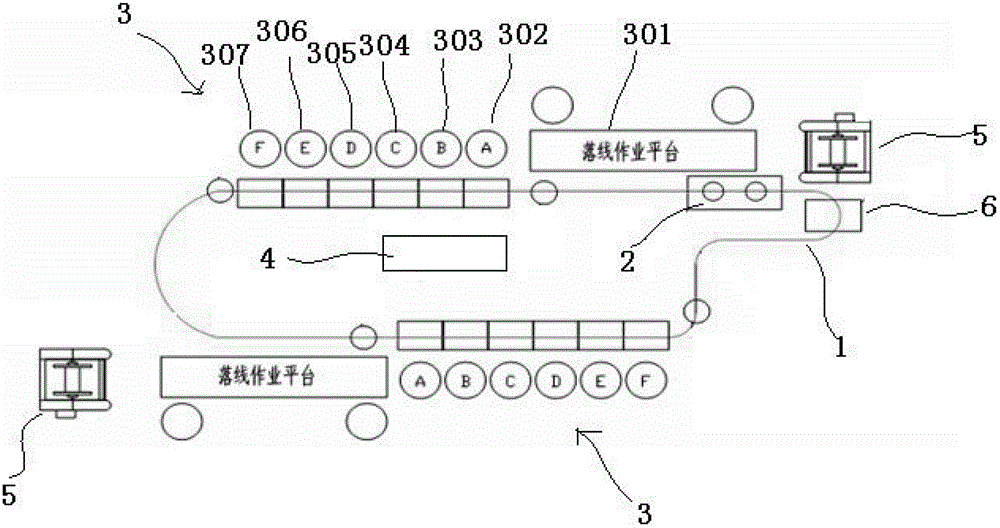

[0026] refer to figure 2 and image 3 As shown, the circular assembly line includes: a straight track, the bend of the straight track is transitionally connected by a horizontal curved rail, the linear track and the horizontal curved rail form a closed main frame of the circular assembly line,

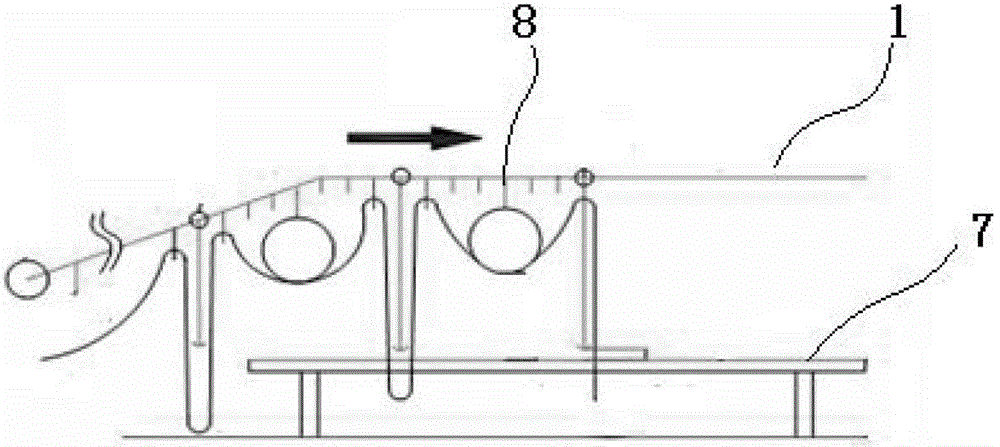

[0027] A desktop 7 is arranged above the main frame of the circular assembly line, and a transmission chain 1 is slidably arranged above the desktop 7. The transmission chain 1 is driven by the driving device 2, and the cables are transmitted to at least two groups of operating platforms on the circular assembly line through the transmission chain 1. 3.

[0028] In a preferred embodiment of the present invention, each group of operating platforms 3 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com