Highly-resistant-to-color-changing gold anti-corrosion copper alloy and panel preparing method thereof

A color-changing gold and copper alloy technology, which is applied in the field of preparation of high color-resistant and high-corrosion CuZnAlNiSiCeB-based gold-colored copper alloys, can solve the problem of not meeting the requirements of golden color and high corrosion resistance, insufficient corrosion resistance of alloys, and undesigned semi-finished products. Continuous casting process and other issues, to achieve the effect of excellent cold working performance, saving processing cost, excellent anti-tarnish performance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]The components are: Cu: 78.5wt%, Al: 2.0wt%, Ni: 0.5wt%, B: 0.005wt%, Ce: 0.1wt%, Si: 0.2wt%, the balance is Zn and unavoidable impurities 1# alloy and Cu: 78.5wt%, Al2.3wt%, Ni: 0.5wt%, B: 0.005wt%, Ce: 0.1wt%, Si: 0.5wt%, the balance is Zn and unavoidable impurities 2 #Alloy, according to the steps (1)-(10) of "Content of the Invention", make a plate with a thickness of 2 ± 0.05mm. Wherein in the step (4), the hot rolling pass deformation is about 60%, and the total deformation is 90%; in the step (6), the cold rolling pass deformation is about 50%, and the total deformation is about 70%; in the step (7), The annealing temperature is 700°C, and the annealing time is 1 hour; the cold finish rolling deformation in step (9) is about 33%; the annealing temperature of the finished product in step (10) is 700°C, and the annealing time is 1 hour. The above two plates and the existing HSn72-1-1 plate for coinage are processed into blank cakes, and after polishing, the gold co...

Embodiment 2

[0049] The components are: Cu: 78.5wt%, Al: 2.0wt%, Ni: 0.5wt%, B: 0.005wt%, Ce: 0.1wt%, Si: 0.2wt%, the balance is Zn and unavoidable impurities 1# alloy and Cu: 78.5wt%, Al2.3wt%, Ni: 0.5wt%, B: 0.005wt%, Ce: 0.1wt%, Si: 0.5wt%, the balance is Zn and unavoidable impurities 2 #Alloy, according to the steps (1)-(10) of "Content of the Invention", make a plate with a thickness of 2 ± 0.05mm. Wherein in the step (4), the hot rolling pass deformation is about 60%, and the total deformation is 90%; in the step (6), the cold rolling pass deformation is about 50%, and the total deformation is about 70%; in the step (7), The annealing temperature is 700°C, and the annealing time is 1 hour; the cold finish rolling deformation in step (9) is about 33%; the annealing temperature of the finished product in step (10) is 700°C, and the annealing time is 1 hour. The above-mentioned plates and HAl77-2B, HSn70-1A and HSn72-1-1 plates commonly used in the market are processed into blank cakes...

Embodiment 3

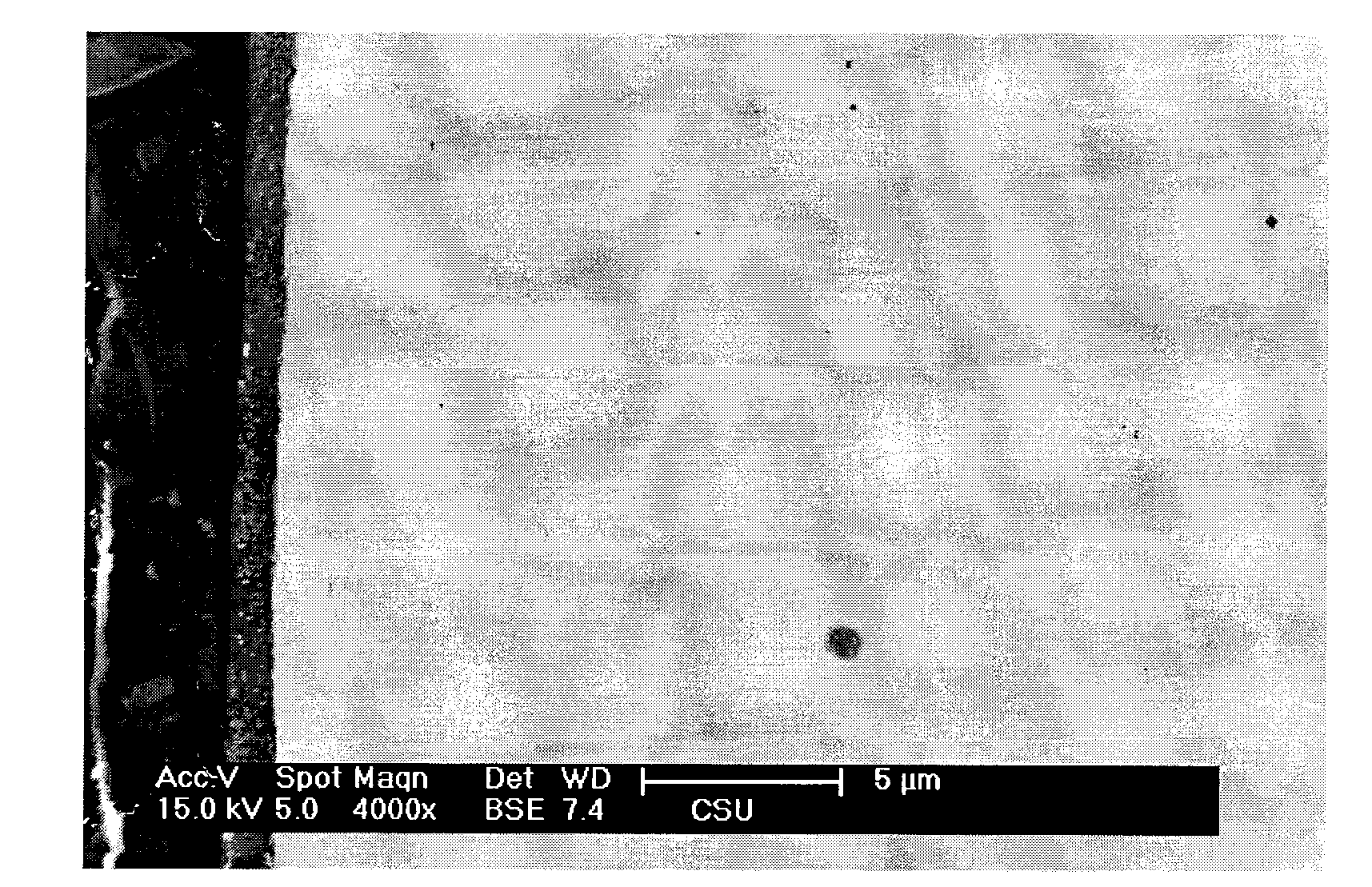

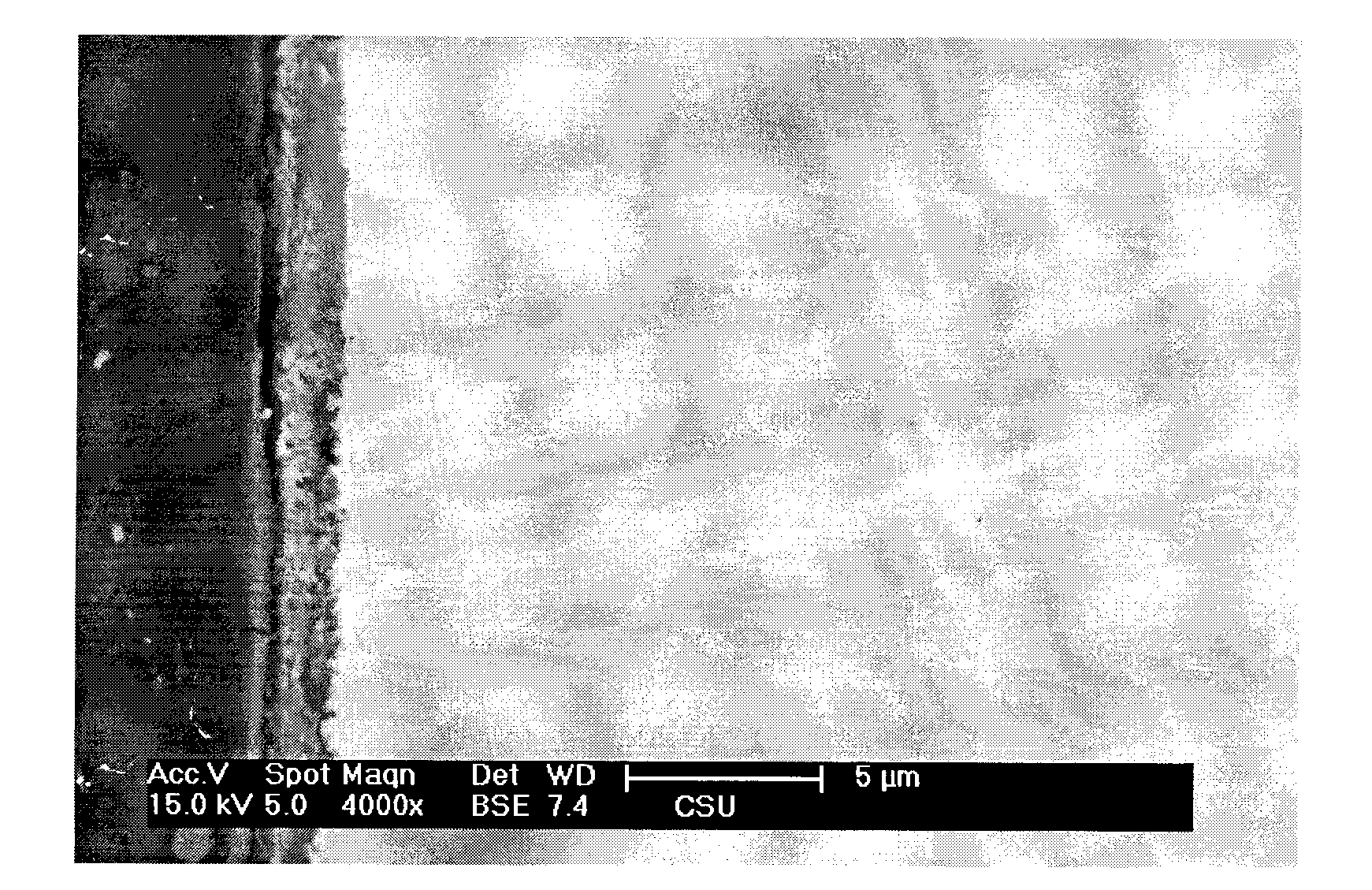

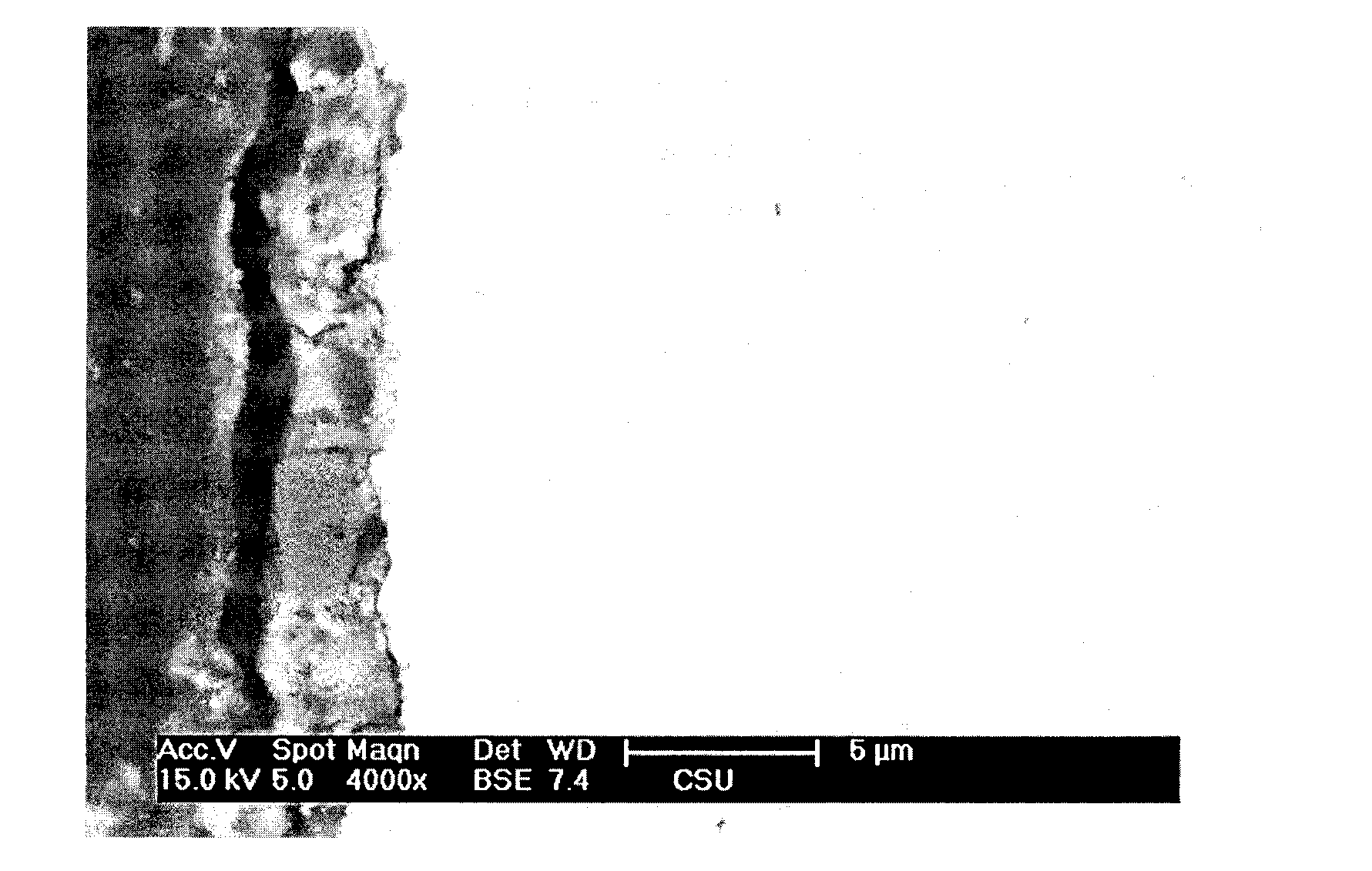

[0054] The composition Cu: 78.5wt%, Al: 2.0wt%, Ni: 0.5wt%, B: 0.005wt%, Ce: 0.1wt%, Si: 0.2wt%, the balance is Zn and 1# of unavoidable impurities Alloy, according to the steps (1)-(10) of "Content of the Invention" to make a plate with a thickness of 2±0.05mm. Wherein in the step (4), the hot rolling pass deformation is about 60%, and the total deformation is 90%; in the step (6), the cold rolling pass deformation is about 50%, and the total deformation is about 70%; in the step (7), The annealing temperature is 700°C, and the annealing time is 1 hour; the cold finish rolling deformation in step (9) is about 33%; the annealing temperature of the finished product in step (10) is 700°C, and the annealing time is 1 hour. Process the above plates and HAl72-2B, HSn72-1-1 plates into blank cakes. After polishing, they are exposed to salt spray environment for 24 hours according to the method of GB / T10125-1997, and then observe the morphology of the corrosion layer. figure 1 It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com