Direct type backlight module and liquid crystal display device

A backlight module, direct type technology, applied to lighting devices, fixed lighting devices, components of lighting devices, etc., can solve the problems of large thickness of direct type backlight structures, use a lot, increase the cost of liquid crystal display devices, etc. The effect of power consumption and light mixing distance, increasing luminous efficiency, and reducing light mixing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

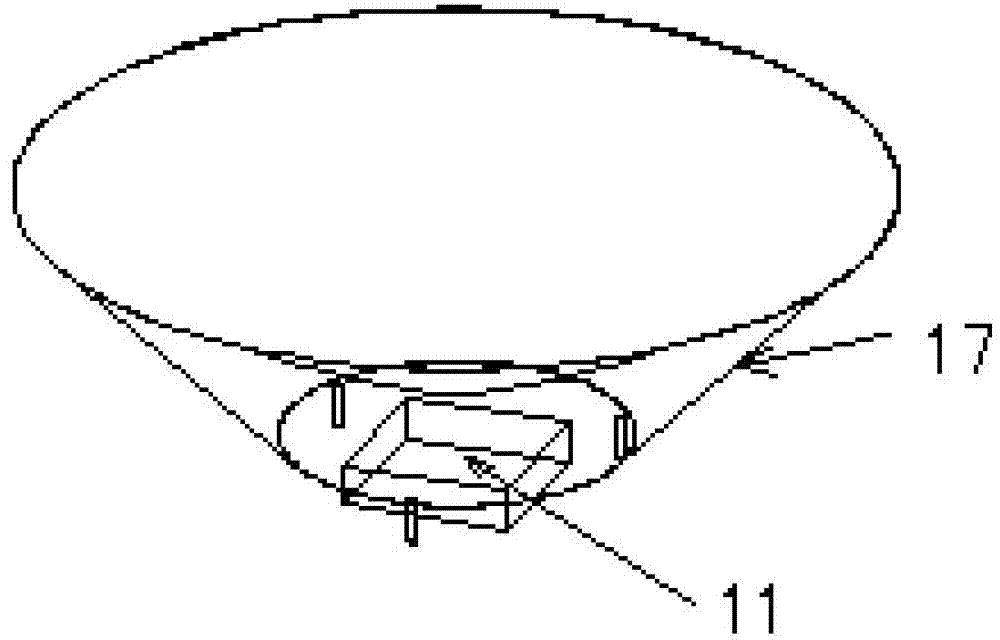

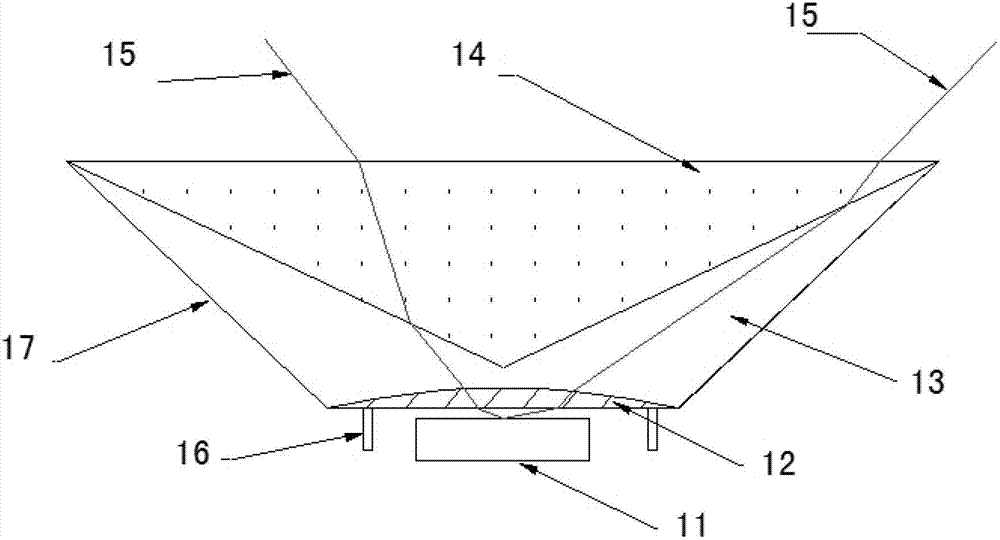

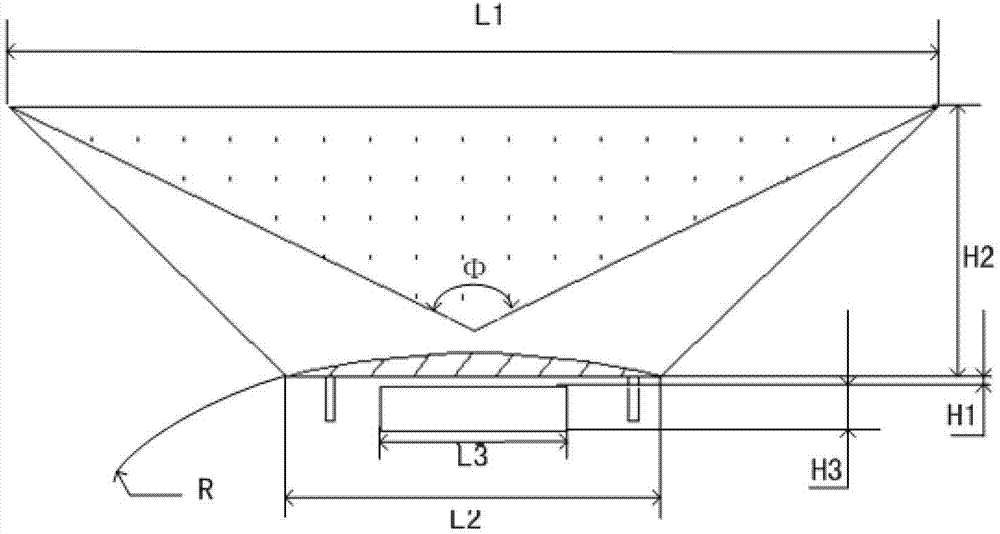

[0051] In this embodiment, the width of the LED light bar 11 is L3, the thickness of the LED light bar 11 is H3, the diameter of the first refraction structure 14 is L1, the diameter of the second refraction structure 12 is L2, the legs 16 and the LED light bar 11 The height difference is H1, and the height of the secondary lens structure 17 is H2. The first refraction structure 14 is a cone, the cone angle is Φ; the second refraction structure 12 is arc spherical, and the radius of curvature is R; wherein, the first refraction structure 14 and the second refraction structure 12 are made of optical glass BK7, All parameters meet the following conditions:

[0052] L1=2.5L2, L2=1.8L3, H1=0.2H3, cone angle Φ=135°, R=5H3, H2 can be set according to L1, L2, Φ, R.

[0053] Such as Figure 4 As shown, the light distribution curve of the LED light bar in the existing backlight module is a Lambertian distribution, and the angle of the strongest light intensity is 0°; Figure 5 As sh...

Embodiment 2

[0056] In this embodiment, the width of the LED light bar 11 is L3, the thickness of the LED light bar 11 is H3, the diameter of the first refraction structure 14 is L1, the diameter of the second refraction structure 12 is L2, the legs 16 and the LED light bar 11 The height difference is H1, and the height of the secondary lens structure 17 is H2. The first refraction structure 14 is a cone, the cone angle is Φ; the second refraction structure 12 is arc spherical, and the radius of curvature is R; wherein, the first refraction structure 14 and the second refraction structure 12 are made of optical glass BK7, All parameters meet the following conditions:

[0057] L1=2L2, L2=1.5L3, H1=0.2H3, cone angle Φ=135°, R=5H3, H2 can be set according to L1, L2, Φ, R.

[0058] Depend on Figure 8 It can be seen that when both L1 and L2 are at the limiting limit, the light emitted by the LED light strip at a large angle is not captured by the second refraction structure, so there will be...

Embodiment 3

[0061] In this embodiment, the width of the LED light bar 11 is L3, the thickness of the LED light bar 11 is H3, the diameter of the first refraction structure 14 is L1, the diameter of the second refraction structure 12 is L2, the legs 16 and the LED light bar 11 The height difference is H1, and the height of the secondary lens structure 17 is H2. The first refraction structure 14 is a cone, the cone angle is Φ; the second refraction structure 12 is arc spherical, and the radius of curvature is R; wherein, the first refraction structure 14 and the second refraction structure 12 are made of optical glass BK7, All parameters meet the following conditions:

[0062] L1=2.5L2, L2=1.8L3, H1=0.2H3, cone angle Φ=160°, R=5H3, H2 can be set according to L1, L2, Φ, R.

[0063] Depend on Figure 9 It can be seen that when other parameter settings are the same as those in Example 1, when the cone angle of the first refraction structure is set at the maximum allowable value, the modulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com