Gauge for measuring short inner cone

A technology of inner cone and cone, which is applied in the field of mechanical processing measuring tools, can solve the problems of large height error, inaccurate taper measurement, unqualified, etc., and achieve the effect of improving production efficiency, reasonable measurement method, and ensuring the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

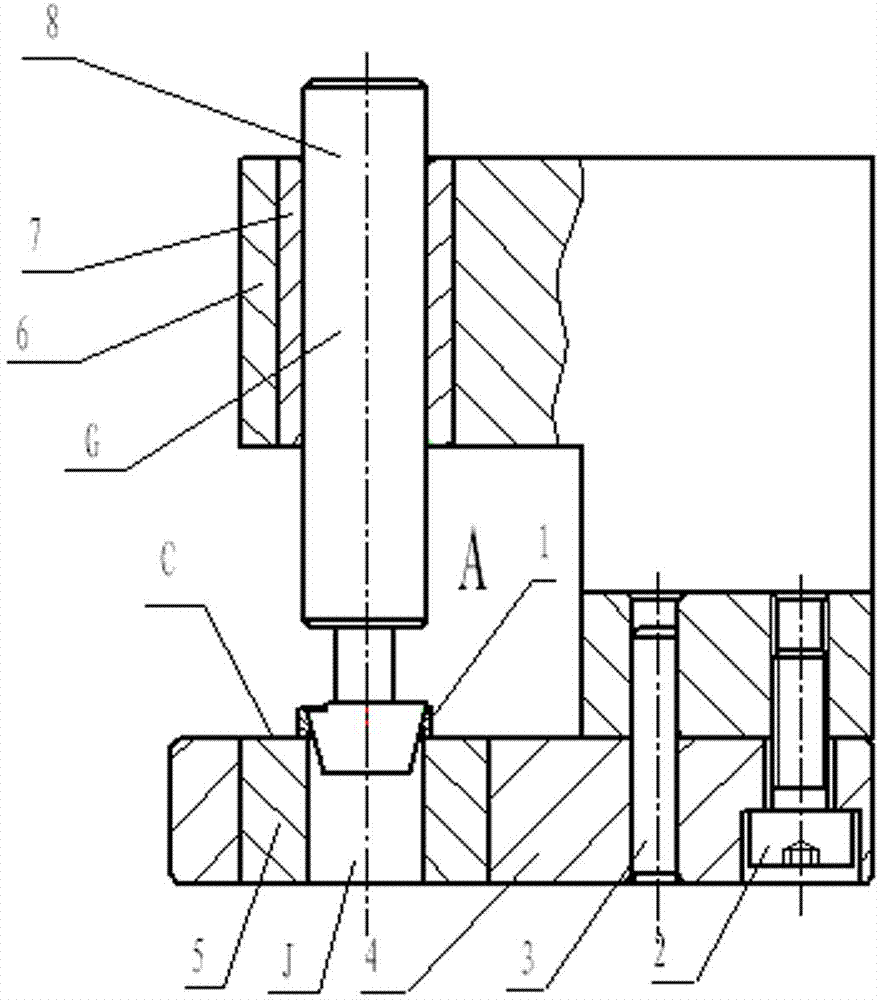

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

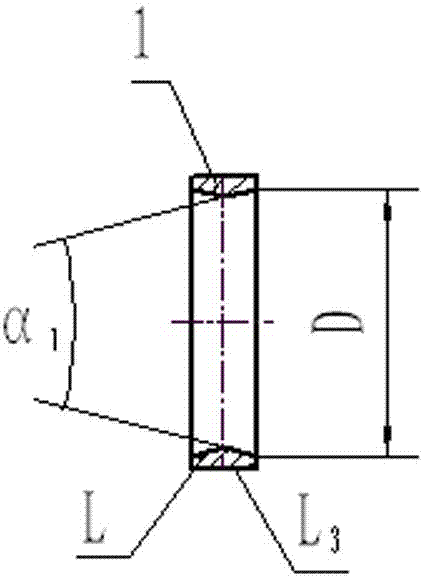

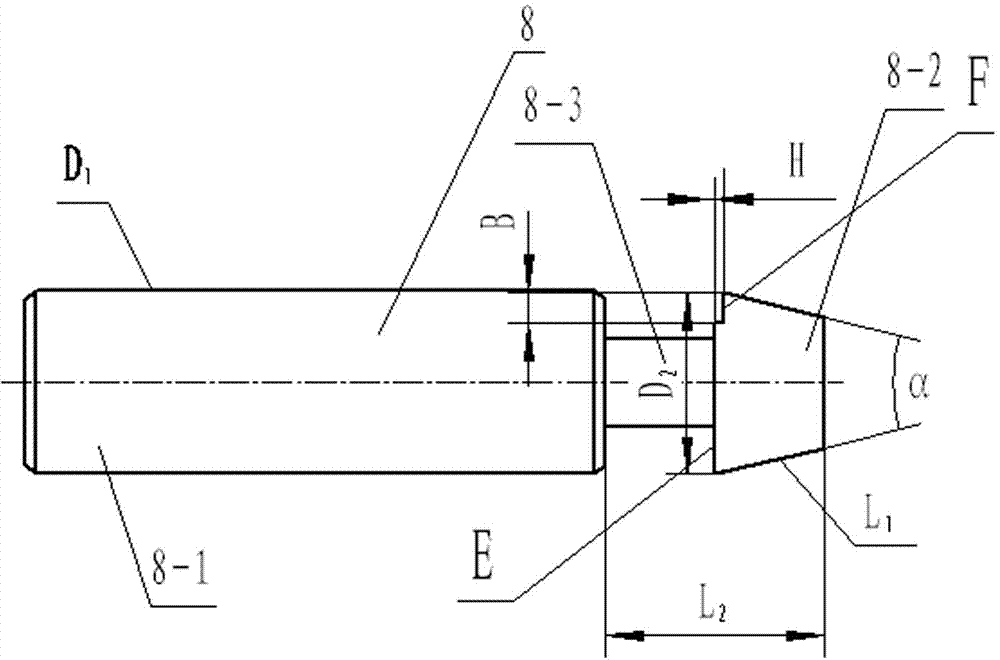

[0022] see figure 1 As shown, the short inner conical part 1 detected by the present invention has a taper end face diameter D And the length L of the tapered surface, the diameter D of the tapered end surface is much greater than 16mm, while the length L of the tapered surface is less than 3mm, and the total thickness L of the length L of the tapered surface And smaller, less than 6mm. Therefore, it is quite difficult to measure the taper and the end face diameter D of the short inner cone part 1. If the measurement is inaccurate, it will directly affect the assembly height and stress condition of the short inner cone part 1; at the same time, if the short inner cone can be accurately measured The actual size of the diameter D of the end surface of the part 1 can use the precision of the machine tool to complete accurate feed processing, ensure the pass rate of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com