Textile fabric wet motion viscous deformation behavior characterization method and device

A textile fabric, wet state technology, applied in the field of textile fabric testing, can solve the problem of not reflecting the actual situation of sticky body in sweaty fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

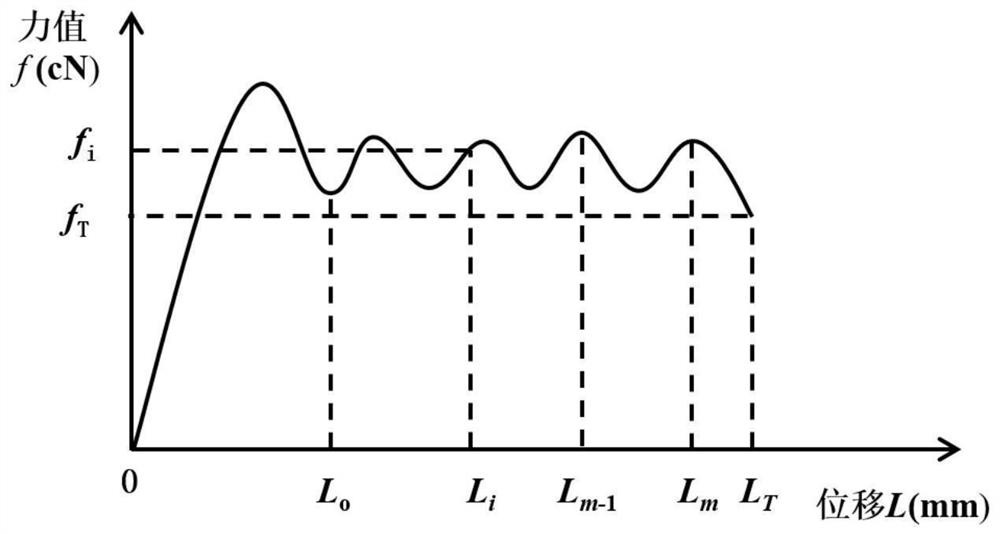

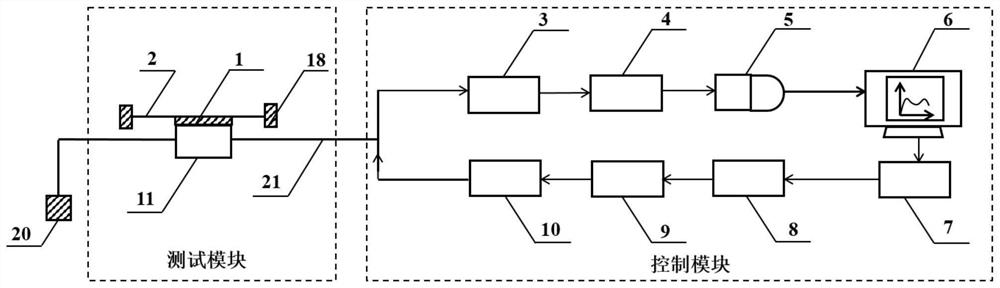

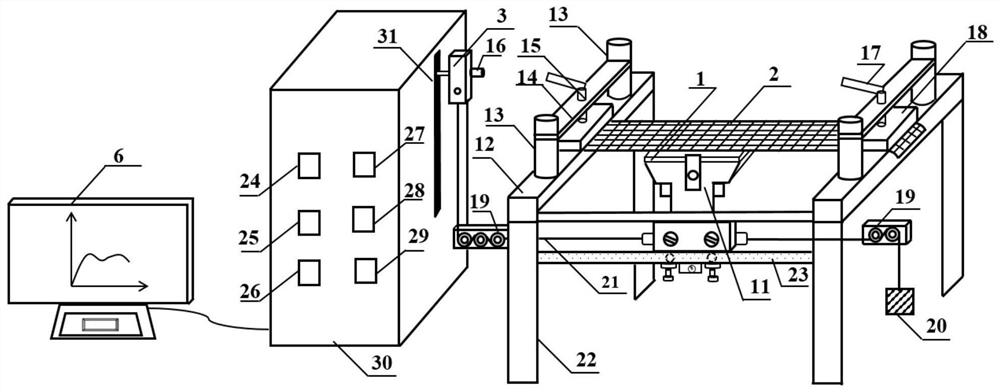

Method used

Image

Examples

example 1

[0081] Fabric sample: 100% shrink-resistant wool knitted fabric, weft plain stitch, transverse density 95.0 ( / 5cm), longitudinal density 105.0 ( / 5cm), unit area weight 1.56g / cm 2 , cut 5 rectangular samples, the size of which is 20.0cm×5.0cm.

[0082] Test each sample according to the above steps [1] to [8], wherein the test parameters set in step [4] are: moving speed 200mm / min, skin area 24.00cm 2 , The displacement range is 0~80mm. After the test of 10 samples is completed, the test curve displayed on the main test interface of the computer is as follows: Figure 5 As shown, the test indicators and statistical data are shown in the table below.

[0083]

example 2

[0085] Fabric sample: plain weave pure cotton fabric sample, warp density 250 ( / 10cm), weft density 110 ( / 10cm), warp tightness 49.95%, weft tightness 21.98%, at 15.0cN / cm 2 The thickness under pressure is 1.42mm, and the weight per unit area is 187g / cm 2 , cut out 10 rectangular samples with a size of 20.0cm×5.0cm.

[0086] The test parameters set in step [4] are: moving speed 200mm / min, initial load 20.00cN, skin area 24.00cm 2 , The displacement range is 0~80mm. After the test of 10 samples is completed, the test curve displayed on the main test interface of the computer is as follows: Figure 6 , test indicators and statistical data are shown in the table below.

[0087]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com