Depth-control drill test device and test method for PCB (printed circuit board)

A technology for PCB board and drilling inspection, applied in measuring devices, optical devices, instruments, etc., can solve the problems of difficult monitoring, instability, and inability to detect drilling depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

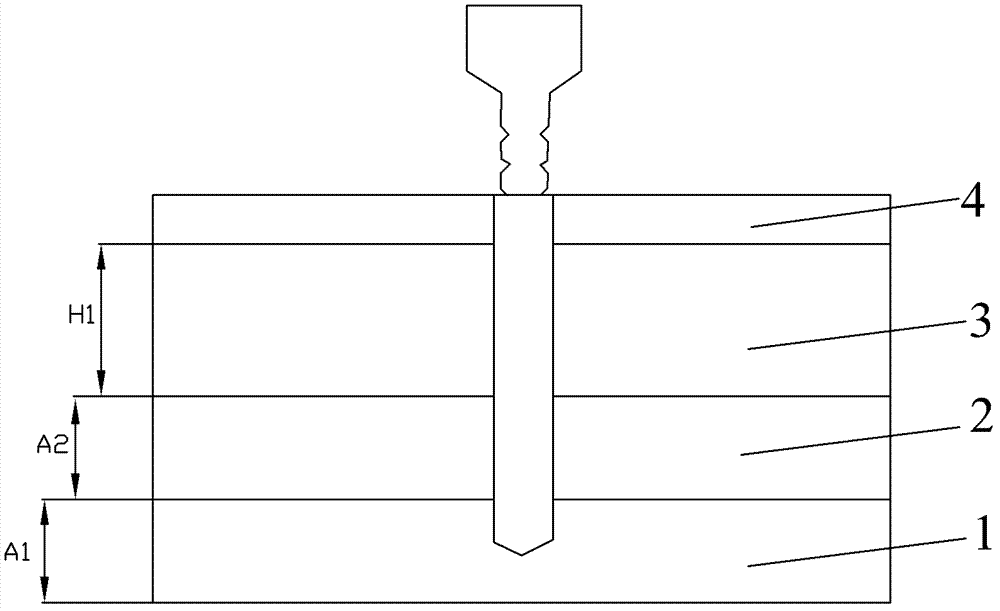

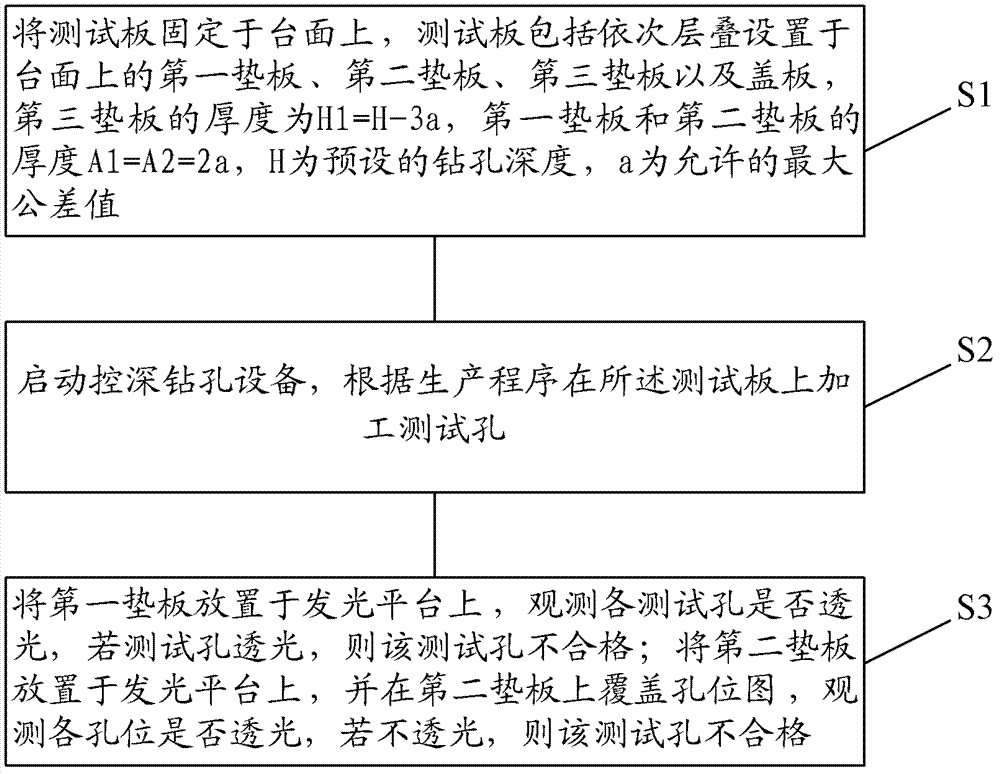

[0014] figure 1 It is a structural diagram of the PCB board depth-controlled drilling inspection device of the present invention. As shown in the figure, the PCB board depth control drilling inspection device of the present invention includes a first backing plate 1 , a second backing plate 2 , a third backing plate 3 and a cover plate 4 which are sequentially stacked from bottom to top. Wherein, the thickness of the third backing plate 3 is H1=H-3a, the thicknesses of the first backing plate 1 and the second backing plate 2 are A1, A2 respectively, and A1=A2=2a, wherein, H is the preset diamond Hole depth, a is the maximum tolerance value allowed, if the drilling error exceeds ±a, it means that the drilling is unqualified. The inspection device can simultaneously inspect all depth-controlled drilling holes with the same preset depth.

[0015] During the production process of the PCB board, the cover plate 4 is used to cover the upper surface of the PCB board during deep dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com