Windage-yaw prevention insulating spacer

A technology for insulating intervals and preventing wind deflection. It is applied to devices for maintaining the distance between parallel conductors and mechanical vibration attenuation devices. It can solve problems such as regular maintenance, mixing of transmission and distribution lines, and easy crushing of wires, so as to reduce maintenance and rush repairs. cost, ensure safe and stable operation, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

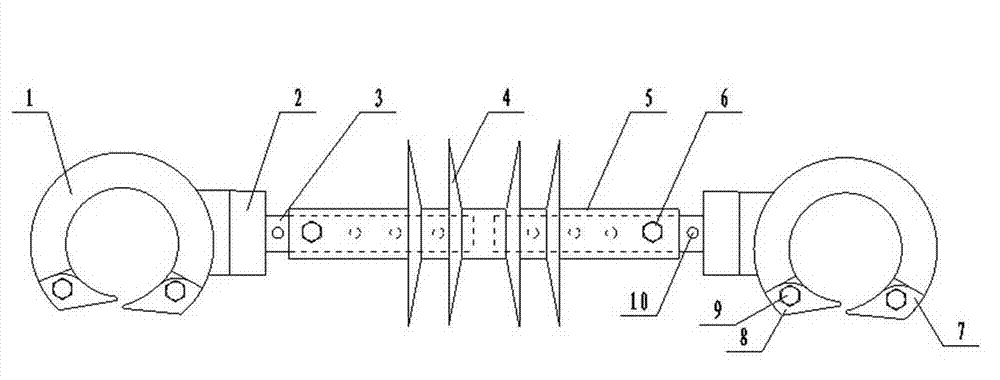

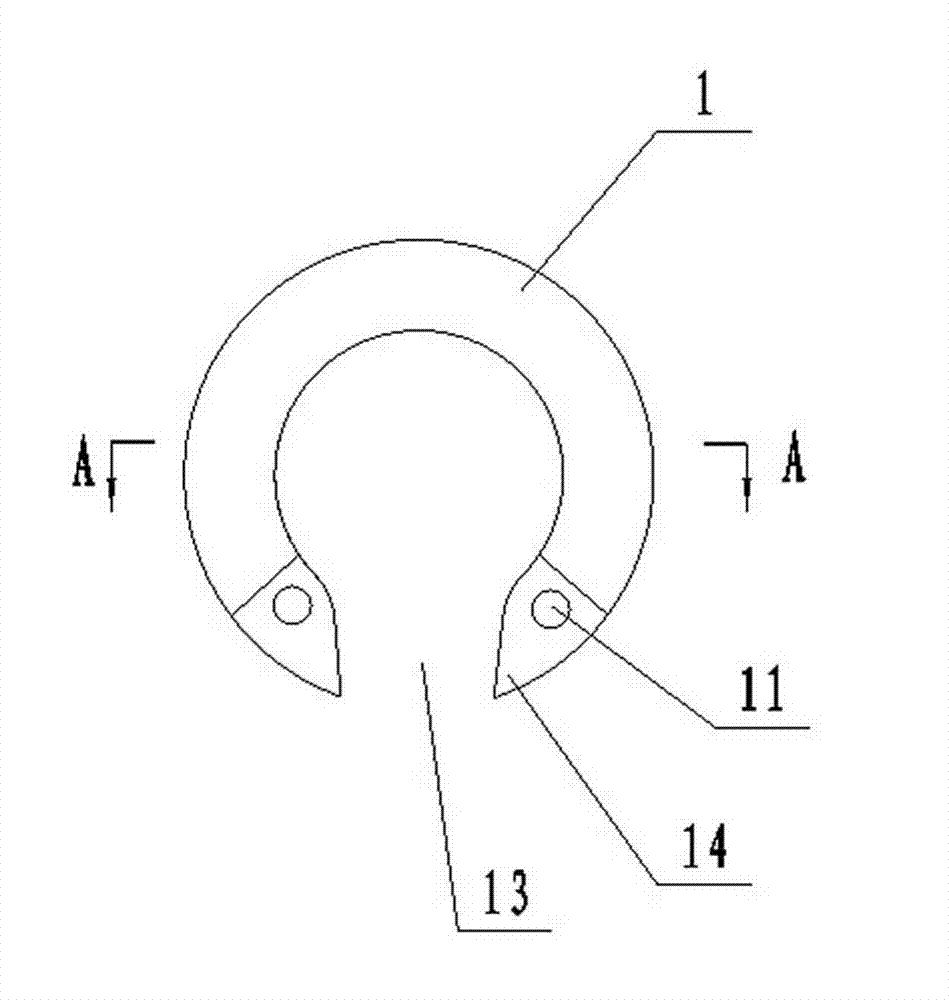

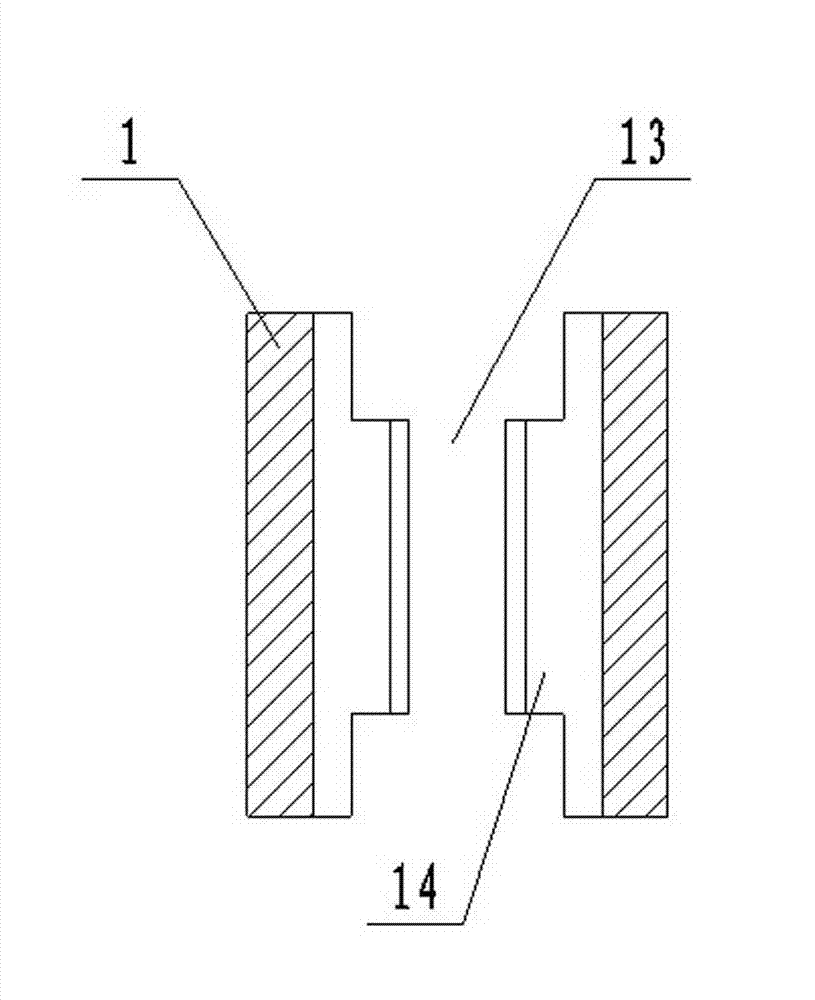

[0018] Embodiment 1: by Figure 1 to Figure 6 It can be seen that the windproof bias insulation spacer includes an insulating sleeve 5, and the insulating sleeve 5 is provided with a silicone insulating umbrella 4 at intervals, and is also provided with 2 fixed wire clamps 1, and the two ends of the insulating sleeve 5 pass through the insulating shaft 3 respectively. Connected to the two fixed wire clamps 1, the two fixed wire clamps 1 are provided with lower openings 13, and the two fixed wire clamps 1 are also provided with wire automatic opening and locking mechanisms.

[0019] The structure of the wire automatic opening and locking mechanism is: both ends of the lower opening 13 of the fixed wire clamp 1 are provided with a boss 14 with a slope, and the boss 14 is provided with a first connecting hole 11 , the corresponding positions of the first fixed guide plate 7 and the second fixed guide plate 8 are provided with a second connection hole 12, and the fixed wire clamp ...

Embodiment 2

[0026] Embodiment 2: The automatic opening and locking mechanism is provided with only one fixed guide plate, and the length of the fixed guide plate is correspondingly lengthened so that it can be overlapped on the opposite boss 14, specifically: the fixed guide plate and the fixed wire clamp 1 lower opening A boss 14 of 13 is movably connected by bolts, and after lead is put into from lower opening 13, the fixed guide plate rotates automatically, overlaps on the boss 14 on the opposite side, reaches automatic opening and locking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com