Manufacturing method of aerator impeller and integral injection molding impeller

A manufacturing method and integral injection molding technology, applied in chemical instruments and methods, water aeration, sustainable biological treatment, etc., can solve the problems of no disclosure of the mold structure, no disclosure of the mold release mechanism, affecting the efficiency of oxygen enhancement, etc. Good consistency, high production efficiency, and the effect of improving oxygenation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

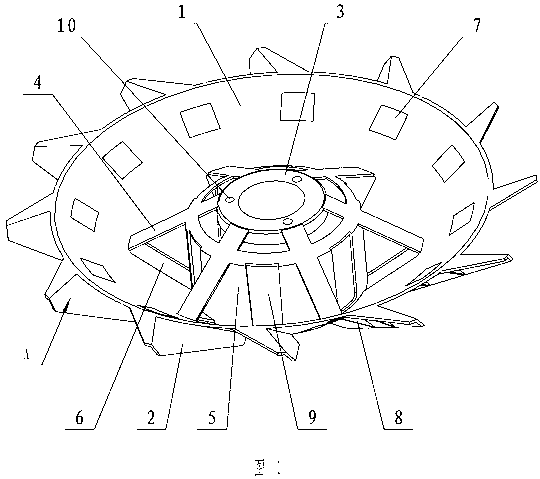

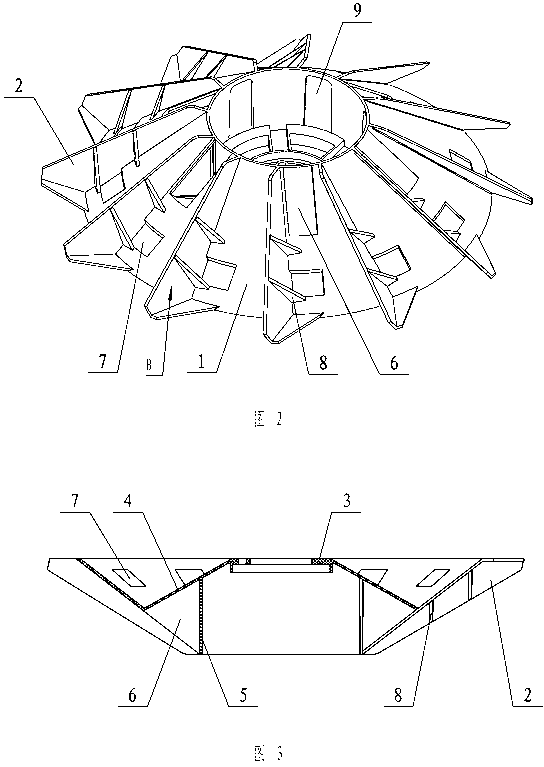

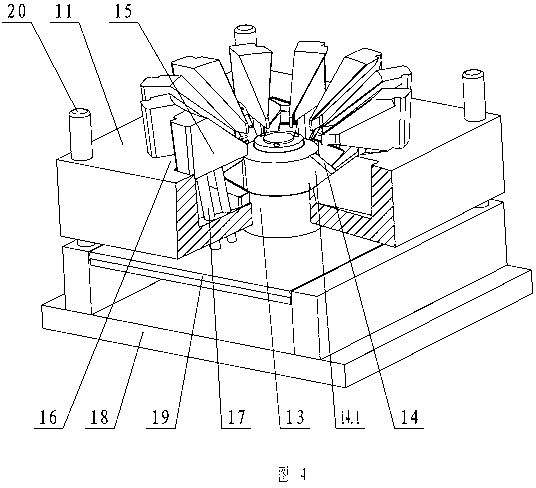

[0021] The present invention will be further described below with specific embodiment, see Figure 1-6 :

[0022] An injection molded impeller of an aerator is mainly composed of: a cone 1, a blade 2, a fixed plate 3, an upper support plate 4, a lower support plate 5, etc. The fixed plate 3 is formed with a connecting hole 10, and the connecting hole 10 can be fixed by bolts On the rotating shaft of the aerator, the fixed plate 3 is connected to the cone body 1 through the upper support plate 4 and the lower support plate 5, and the outer cone surface of the cone body 1 is connected with a plurality of blades 2, and the back side B of the blade has reinforcing ribs 8 to support the blade , be shaped on window 7 in the space of rib 8. There is a window 6 below the upper support plate 4, and the window 6 is designed for the mold structure. Its unexpected effect is to make the water in the cone 1 flow outward through the window, increase the water exchange capacity, and improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com