Juicer

A juice extractor and juice outlet technology, applied in the field of juice extractors, can solve the problems of reduced service life, uncontrollable, parts falling off, etc., and achieve the effects of quickly crushing materials, reducing production costs, and preventing high-speed falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings.

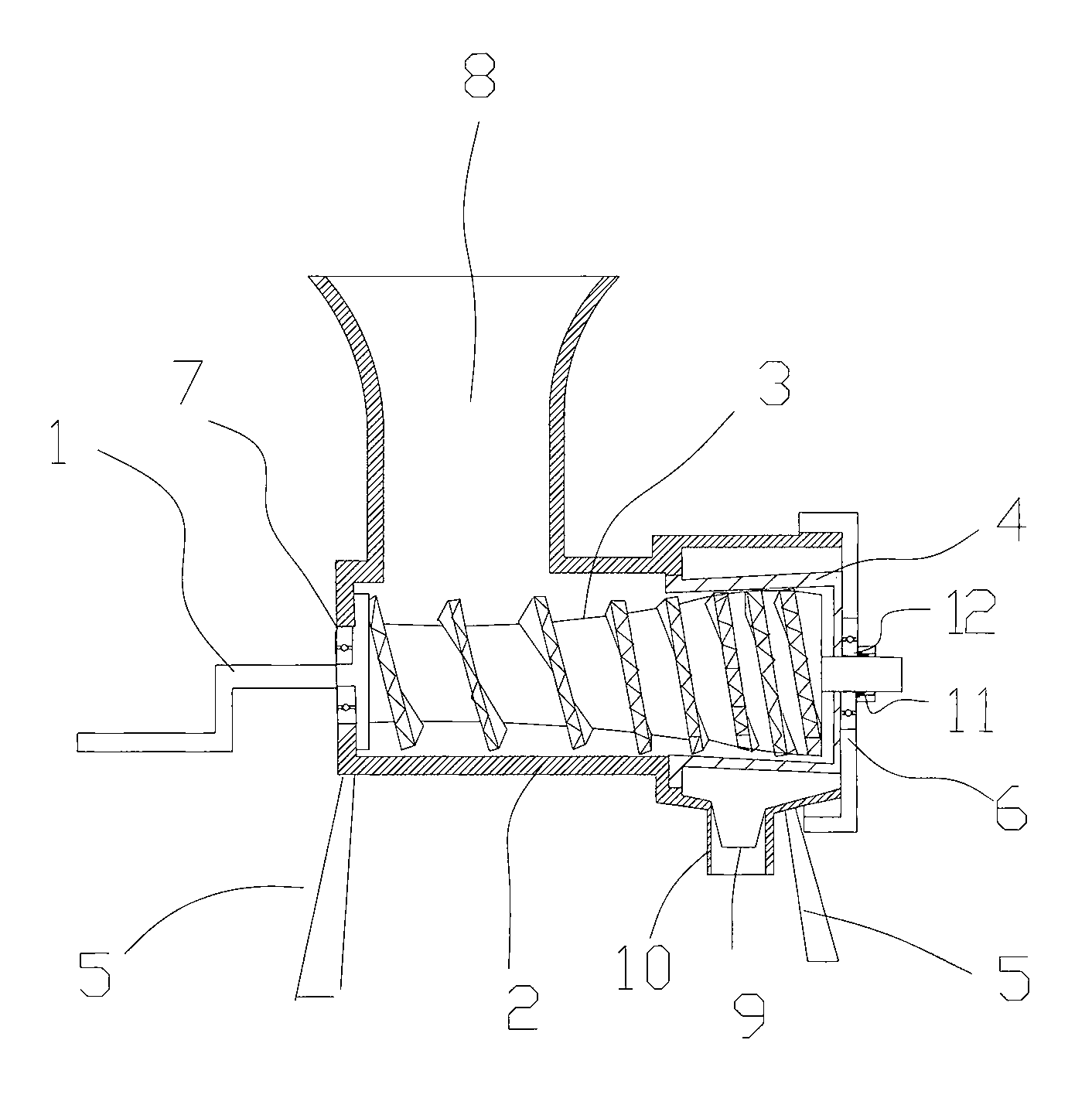

[0009] figure 1 A juice extractor according to an embodiment of the present invention is schematically shown. Such as figure 1 As shown, the juice extractor includes a rocker 1, a screw 3, a first filter screen 4, an extrusion cavity 2, a cavity cover 6 and a support seat 5, the rocker 1 is connected and fixed on one end of the screw 3, and the other end of the screw 3 A cylinder is provided, and the screw 3 is fixed on the cavity cover 6 by a nut 11 from the cylinder. The outer diameter of the screw 3 increases gradually. Small, the end of the screw rod 3 is provided with a cylinder, the end of the cylinder is provided with an external thread, the cylinder passes through the first filter screen 4, the front end of the extrusion chamber 2 is provided with a first ball bearing 7, and the chamber cover 6 is provided with a second The ball bearing 12 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com