Multifunctional mechanical arm type operation device

A technology of multi-functional machinery and working device, applied in the field of robotic arms, which can solve the problems of low degree of freedom, increased working area, and inability to move.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

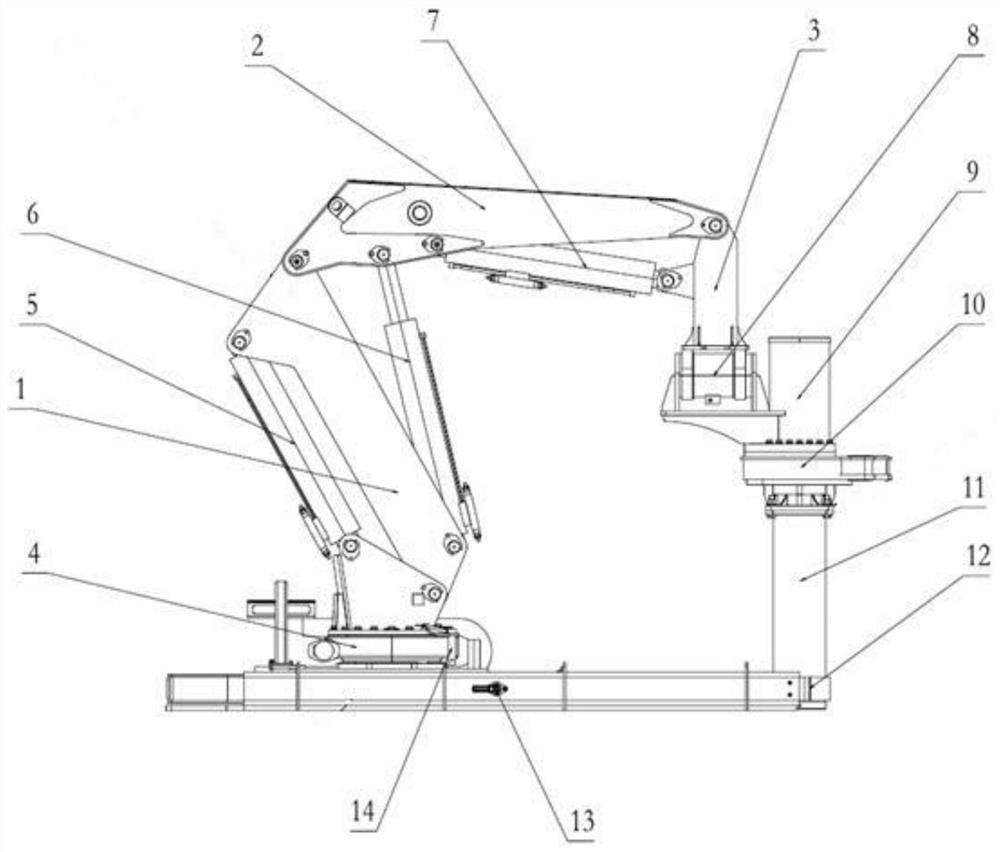

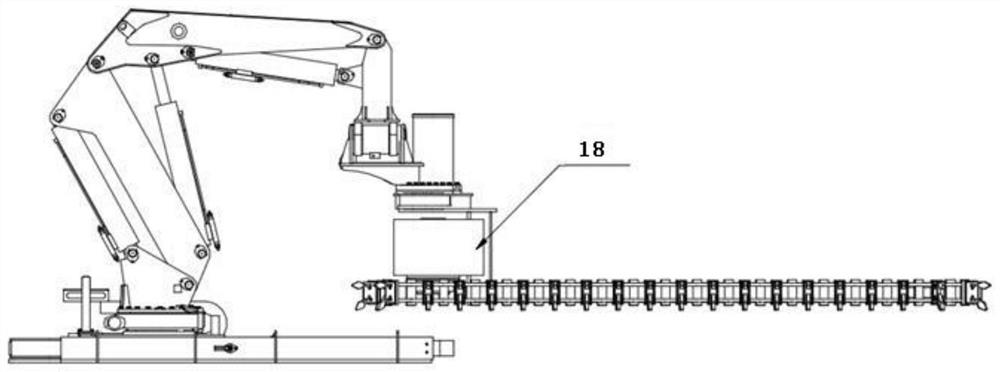

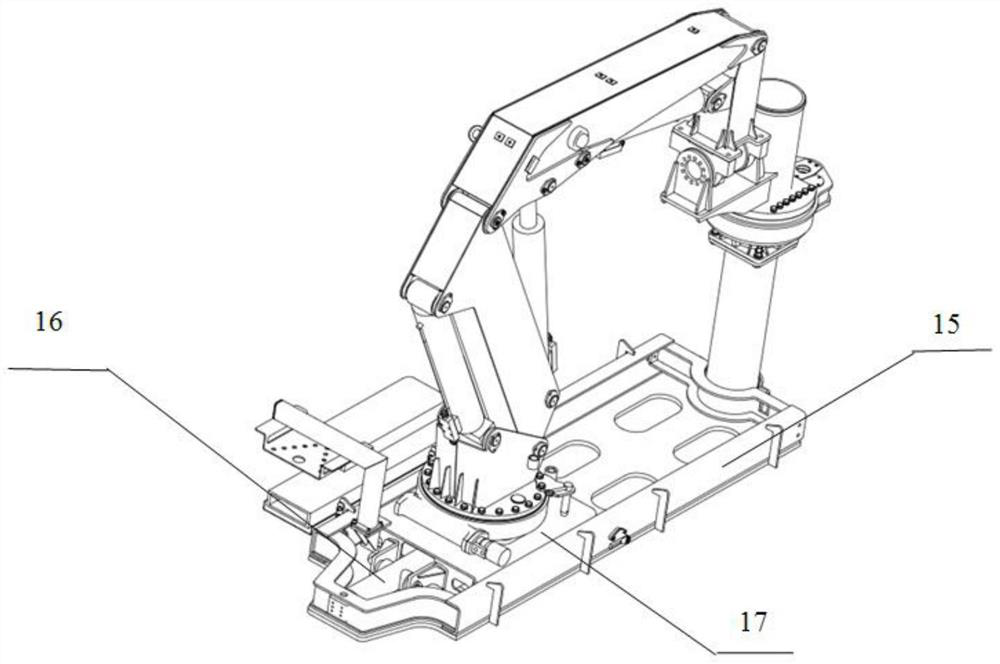

[0045] like figure 1 As shown in the figure, a multifunctional mechanical arm-type working device includes: a sliding mechanism; Movement; working mechanism, installed at the end of the multi-degree-of-freedom robotic arm.

[0046] like figure 1As shown, the multi-degree-of-freedom mechanical arm comprises: the mechanical arm rotating base 4 is connected with the sliding mechanism, and the mechanical arm rotating base 4 can move along the guiding direction of the sliding mechanism, which drives the multi-degree-of-freedom mechanical arm along the sliding mechanism. The guide direction moves; the body of the manipulator is fixed on the rotating base 4 of the manipulator.

[0047] The manipulator rotating base 4 can rotate to drive the manipulator body to rotate.

[0048] like figure 1 As shown, the multi-degree-of-freedom manipulator also includes a primary arm 1, a secondary arm 2 and a tertiary arm 3; wherein: the lower end of the primary arm 1 is hinged with one end of t...

Embodiment 2

[0056] like figure 1 As shown, a twist suction assembly is provided on the intake end of the bottom of the absorption hard pipe 11 .

[0057] like Figure 4 and Figure 5 As shown, the cutter suction assembly includes a first installation sleeve 19 fitted on the air inlet end of the bottom of the absorption hard pipe 11, and a first blade 20 is symmetrically arranged on the outer wall of the first installation sleeve 19. The first blade 20 is connected to the first blade 20. The outer wall of the installation sleeve 19 is connected by a pin. During operation, the rotating suction head 10 drives the absorption hard tube 11 to rotate, the absorption hard tube 11 drives the first installation sleeve 19 to rotate, and the first installation sleeve 19 drives the first blade 20 on the outer wall. Rotating, the first blade 20 cooperates with the work of the swinging oil cylinder 8 to work on the hardened section, so as to achieve efficient maintenance of heavy-duty railway serious ...

Embodiment 3

[0060] like Image 6 and Figure 7 As shown, the cutter suction assembly includes a second installation sleeve 21 fitted on the air inlet end of the bottom of the absorption hard pipe 11, and a second blade 23 is symmetrically arranged on the outer wall of the second installation sleeve 21. The second blade 23 and the second blade The outer wall of the installation sleeve 21 is fixedly connected.

[0061] like Image 6 and Figure 7 As shown, the second blade 23 is provided with a reinforcing rib plate.

[0062] like Image 6 As shown, a plurality of saw teeth 22 are annularly distributed on the bottom inlet of the second installation sleeve 21 .

[0063] During operation, the rotary suction head 10 drives the absorption hard tube 11 to rotate, the absorption hard tube 11 drives the second installation sleeve 21 to rotate, the second installation sleeve 21 drives the second blade 23 on the outer wall to rotate, and the second blade 23 oscillates with it While the oil cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com