Slurry crushing and mixing process

A mixing process and slurry technology, which is applied in the field of ceramic processing, can solve the problems of ineffective motor transmission, reduce the service life of the stirring device, and easy sedimentation of pottery clay, etc., and achieve the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

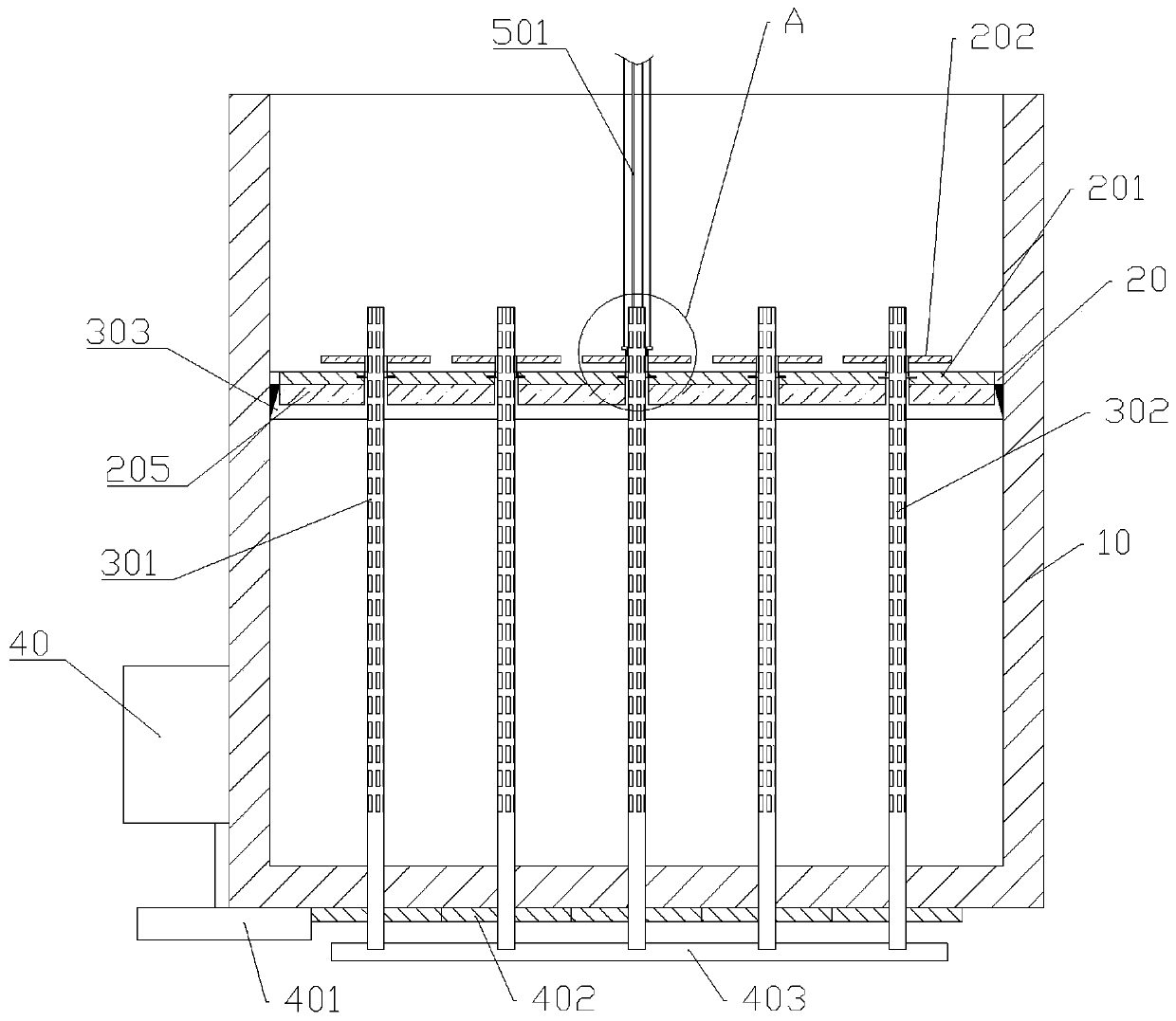

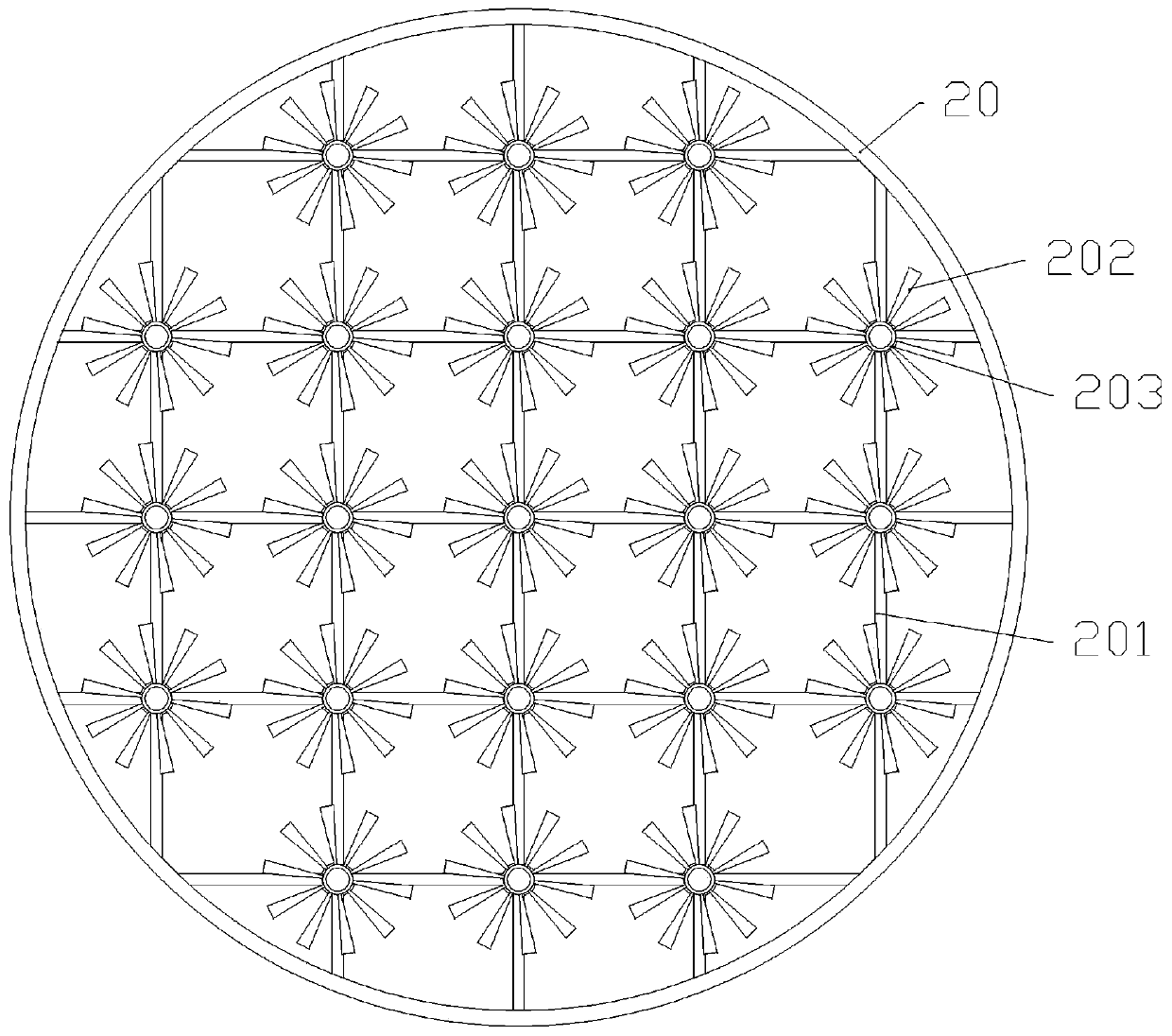

[0022] The reference signs in the drawings of the description include: mixing bucket 10, fixed ring 20, connecting rod 201, blade 202, installation ring 203, boss 204, first blade 205, ejector rod 301, rubber strip 302, second blade 303 , motor 40, driving wheel 401, transmission wheel 402, support seat 403, moving tube 501, connecting block 502.

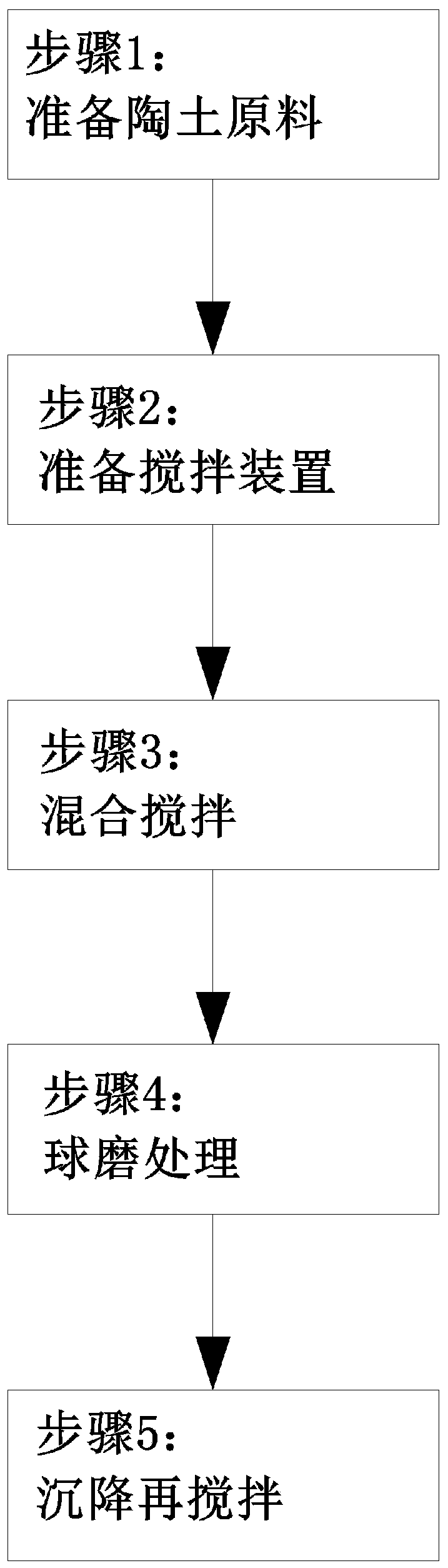

[0023] In the present embodiment, the slurry crushing and mixing process is basically as follows: figure 1 As shown, its specific operation is as follows:

[0024] Step 1: Prepare pottery clay raw material, the quality of pottery clay raw material composition is respectively: Si0 2 : 40kg, Ca0: 21kg, A1 2 0 3 : 14kg, ZnO: 3kg, Ti0 2 : 11kg, K 2 O: 0.6kg, Fe 2 0 3 : 8.2kg, BaO: 4kg; MgO: 3kg.

[0025] Step 2: Prepare the basics as attached figure 2 , attached image 3 And attached Figure 4 The shown stirring device includes a stirring barr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com