Double-edge automatic back-and-forth board edge-cleaning sawing machine

A bilateral, automatic technology, applied in the field of wood board processing, can solve the problem of low efficiency of single-side wood board edge cleaning equipment, and achieve the effects of facilitating automatic control, improving work efficiency, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

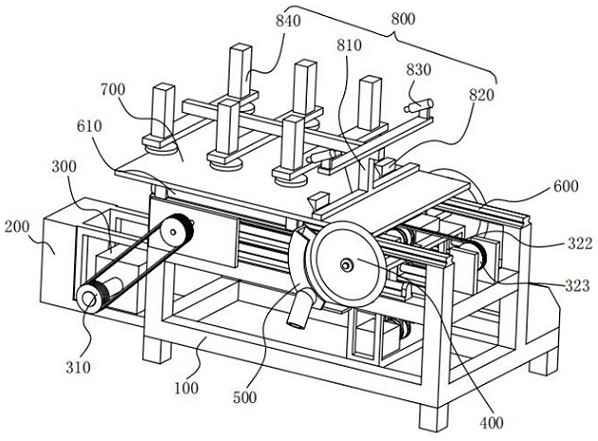

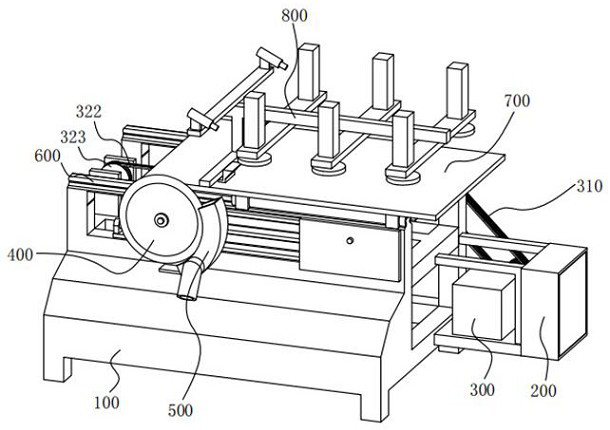

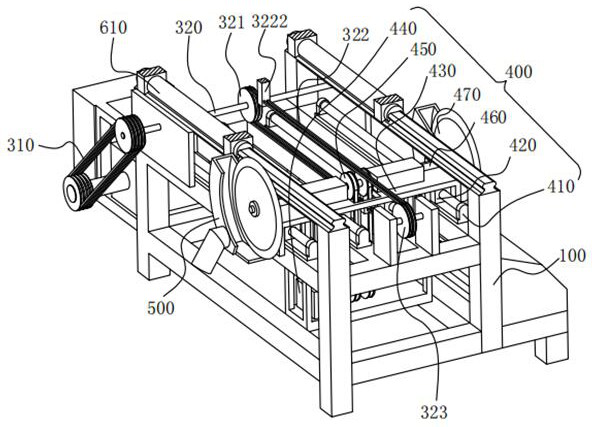

[0040] A double-sided automatic back-and-forth plank edge cleaning machine includes: including: a frame 100; a control electric box 200, the control electric box 200 is installed on the side of the frame 100; a traveling motor 300, the bottom of the traveling motor 300 Installed on the frame 100, the output end of the walking motor 300 is equipped with a walking pulley set 310, the output end of the walking pulley set 310 is equipped with a driving main shaft 320, and the surface of the driving main shaft 320 is fixedly installed with a first A belt pulley 321, the surface of the first belt pulley 321 is connected with the second belt pulley 323 through the transmission of the belt 322, the bottom surface of the belt 322 is fixedly installed with the first linkage block 3221, and the top surface of the belt 322 is fixedly installed with the second linkage Block 3222; the bilateral cutting assembly 400, the bilateral cutting assembly 400 is movably installed on the frame 100; th...

Embodiment 2

[0068] The bilateral cutting assembly 400 includes a first supporting slide rail 410, on which a first moving slider 420 is slidably mounted, and a moving sliding frame 430 is fixedly installed on the top of the first moving sliding block 420 , the cutting motor 440 is installed on the moving carriage 430, the output end of the cutting motor 440 is equipped with a cutting pulley set 450, the output end of the cutting pulley set 450 is equipped with a transmission main shaft 460, the transmission main shaft 460 A cutting disc 470 is fixedly installed at both ends, and a protective assembly 500 is installed on the surface of the moving carriage 430 .

[0069] By installing the cutting pulley group 450 at the output end of the moving carriage 430, the cutting pulley group 450 is convenient to drive the transmission main shaft 460 to rotate and adjust. The function of the synchronous operation of the group cutting cutter head 470 is to facilitate the simultaneous edge cutting of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com