A lower electrode for projection welding with cooling device

A cooling device and electrode technology, which is applied in the field of projection welding machine parts, can solve the problems of short electrode life and poor electrode cooling effect, and achieve the effect of eliminating electrode wear or life reduction, efficient heat dissipation and cooling, and improving the quality of projection welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

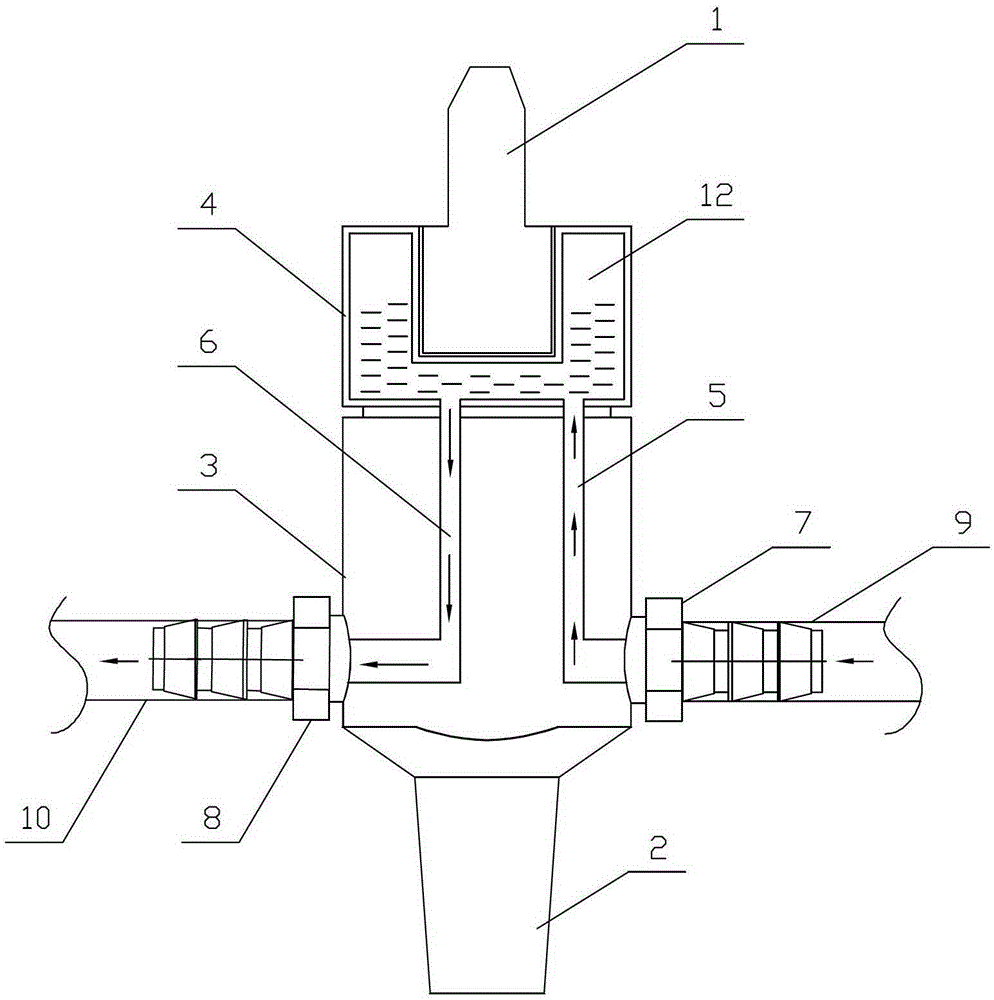

[0022] Embodiment 1: a kind of lower electrode of projection welding with cooling device in this embodiment 1, such as figure 1 As shown, it includes an electrode body made of chrome-zirconium copper and a ceramic positioning pin 1 installed in the electrode body. The electrode body is cylindrical and includes a base 3 and an electrode cap 4 with an integrated structure. The side of the base is designed with a symmetrical clamping profile. The bottom of the base is provided with an electrode interface 2, which is connected to the projection welding machine; a cooling device is designed in the electrode body, including a cooling channel designed in the electrode cap and a water inlet pipe 5 and an outlet pipe 6 respectively connected to the cooling channel in the base , the water inlet pipe is L-shaped, the water inlet of the water inlet pipe is opened on the side wall of the base, the water inlet joint 7 is installed on the water inlet joint, and the water supply pipe 9 for ext...

Embodiment 2

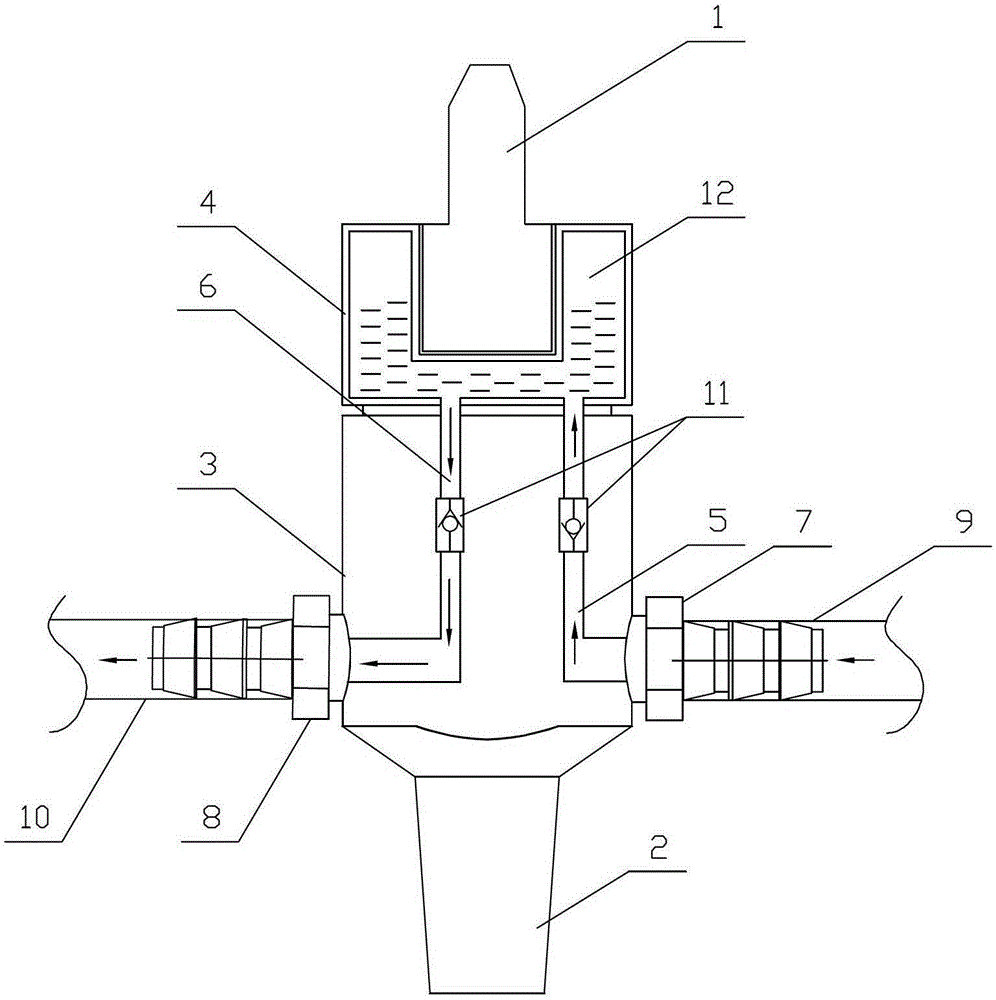

[0024] Embodiment 2: a kind of projection welding lower electrode with cooling device of this embodiment 2, as figure 2 As shown, it includes the electrode body made of chrome-zirconium copper and the ceramic positioning pin installed in the electrode body. A cooling device is designed in the electrode body, including the cooling channel designed in the electrode cap and the water inlet and outlet pipes in the base. A one-way valve 11 is respectively installed in the water pipe and the water outlet pipe. The direction of the one-way valve is consistent with the direction of the water flow. The one-way valve can prevent the cooling water flow from flowing backwards, and the cooling water flow will not be blocked when the cooling water is overheated and vaporized. To reduce the flow rate and flow rate of the cooling water flow to ensure that the electrodes are fully cooled, the other parts of this embodiment 2 are similar to the corresponding parts of the embodiment 1, and will ...

Embodiment 3

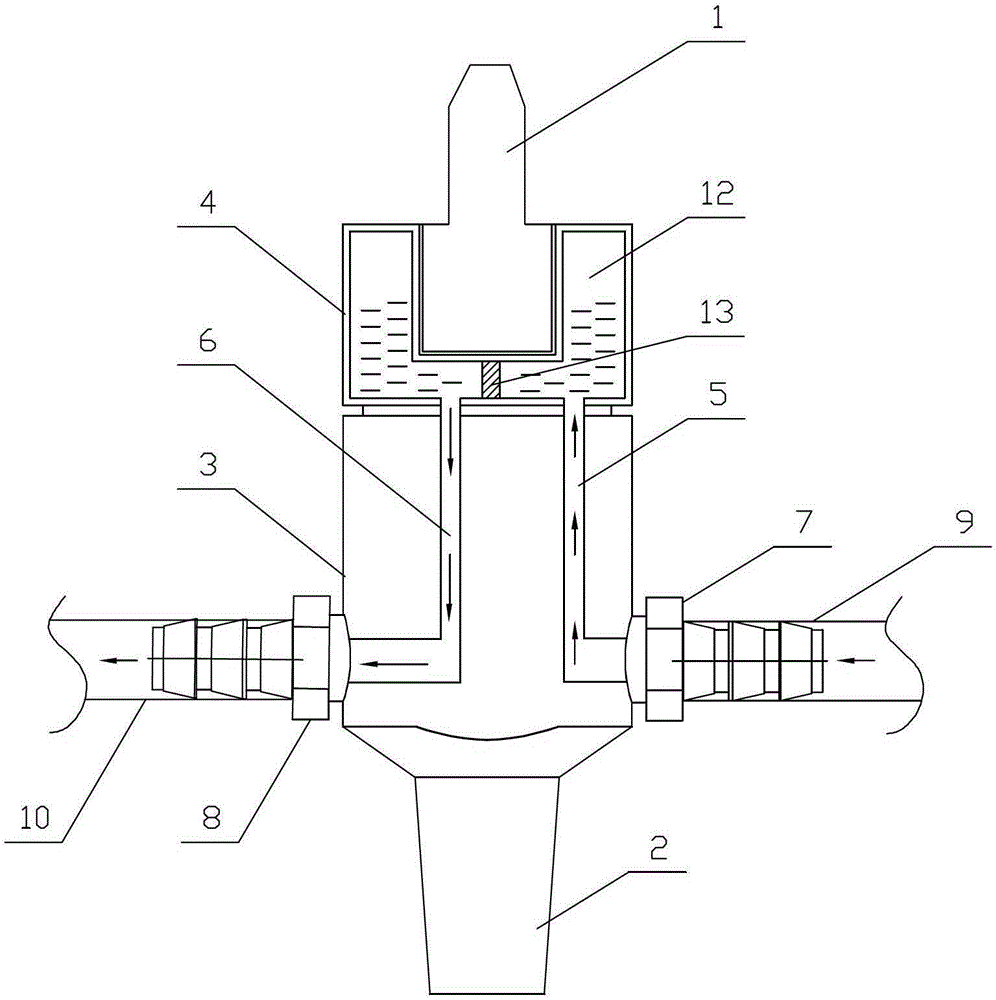

[0025] Embodiment 3: a kind of projection welding lower electrode with cooling device of this embodiment 3, such as image 3 As shown, it includes an electrode body made of chromium-zirconium copper and ceramic positioning pins installed in the electrode body, a cooling device is designed in the electrode body, and a separator 13 perpendicular to the bottom surface of the hollow cavity is designed. The inner side walls of the hollow cavity are connected, and the top of the partition extends to the bottom surface of the concave hole and is connected with the bottom surface. The partition divides the bottom space of the hollow cavity into two semicircular chambers that are open at the top and communicate with each other. The water inlet and the water outlet of the outlet pipe are respectively designed in different chambers. The cooling water flows into one chamber of the hollow chamber through the water inlet pipe, and circulates through the partition to the other chamber and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com