Combined Milling Method and Fixture for Bearing Ball and Socket Swing Nozzle Shell

A processing method and technology of bearing balls, which are used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems such as poor nozzle sealing performance, improve processing accuracy and processing efficiency, uniform clearance, spherical clearance uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

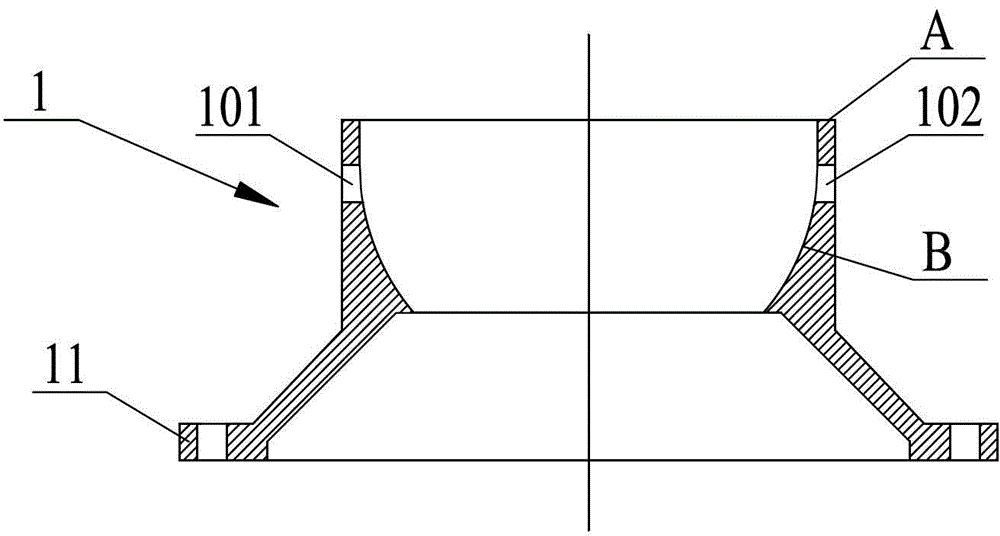

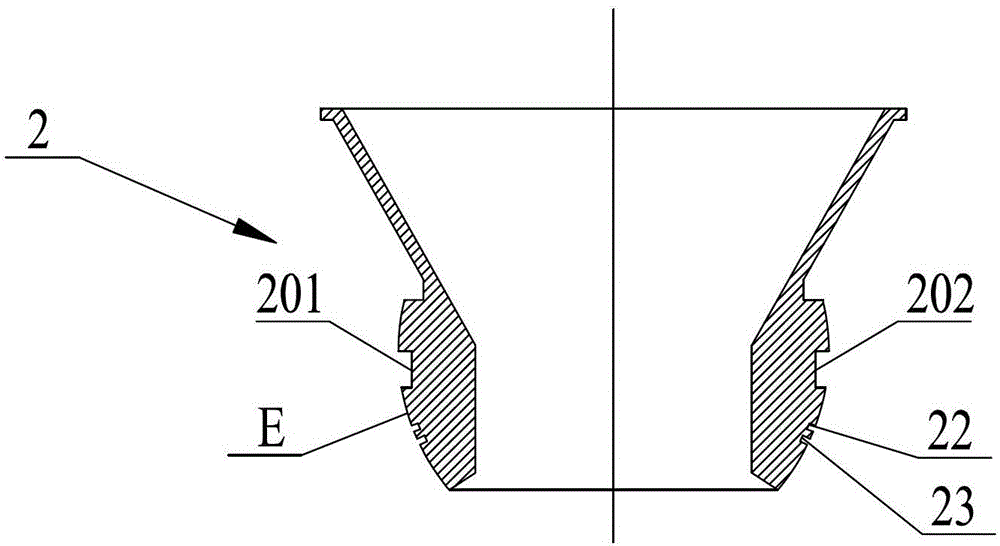

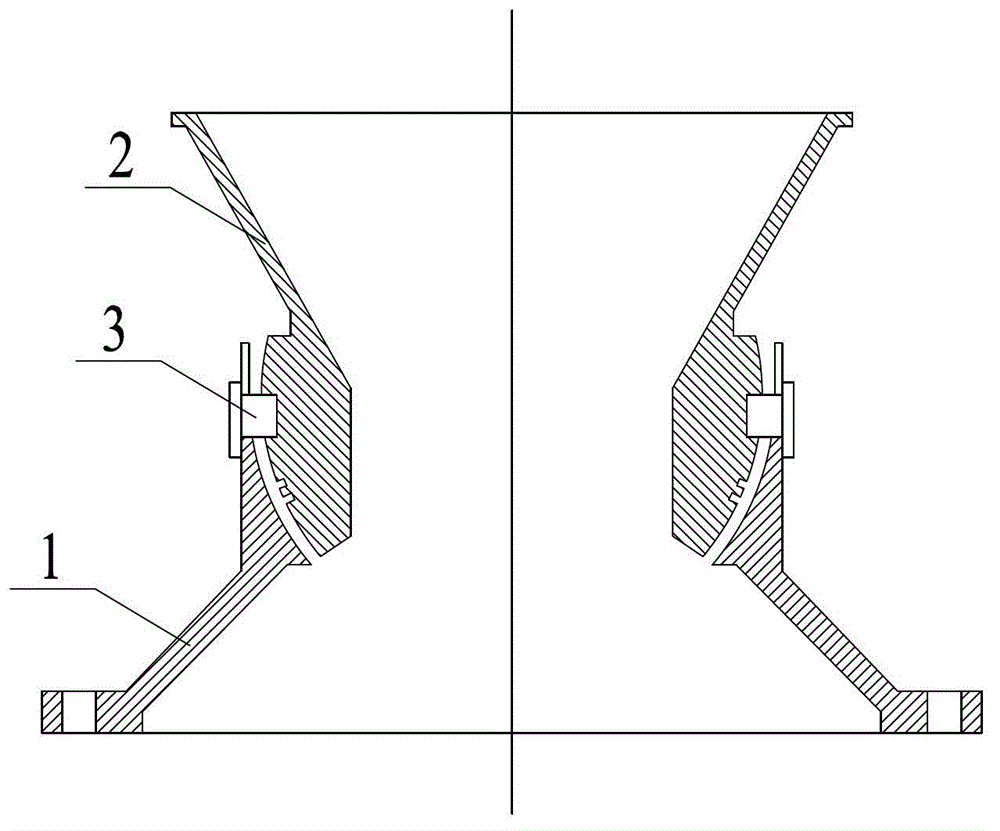

[0034]For a bearing ball-socket oscillating nozzle housing, the inner spherical diameter of the fixed nozzle housing is SR130 mm ± 0.05 mm, and the unilateral gap between the fixed nozzle housing 1 and the movable nozzle housing 2 is required to be 0.1 mm to 0.2 mm , The spherical center of the fixed nozzle shell, the installation hole in the swing shaft, the center axis of the movable nozzle shell and the mounting hole outside the swing shaft coincide, and the positional degree does not exceed ±0.03mm.

[0035] The combined milling method for bearing ball and socket swinging nozzle casing comprises the following steps:

[0036] 1) Install and process the fixed nozzle shell: such as Figure 5 As shown, the fixed nozzle shell blank 10 flange 11 is fixed downward on the fixture, connected and fixed with the fixture, and 12 M15 screws are tightened symmetrically to ensure a firm connection. The fixture is provided with a support ring 7, and the support ring 7 The inner wall has ...

Embodiment 2

[0046] For a bearing ball-socket swinging nozzle housing, the inner spherical diameter of the fixed nozzle housing is SR200 mm ± 0.08mm, and the unilateral gap between the fixed nozzle housing 1 and the movable nozzle housing 2 is required to be 0.15mm to 0.3mm , the center axis of the fixed nozzle shell, the inner mounting hole of the swing shaft, the center axis of the movable nozzle shell, and the outer mounting hole of the swing shaft coincide, and the positional degree does not exceed ±0.05mm.

[0047] The combined milling method for bearing ball and socket swinging nozzle casing comprises the following steps:

[0048] 1) Install and process the fixed nozzle shell: such as Figure 5 As shown, the fixed nozzle shell blank 10 flange 11 is fixed downward on the fixture, connected and fixed with the fixture, and 12 M15 screws are tightened symmetrically to ensure a firm connection. The fixture is provided with a support ring 7, and the support ring 7 The inner wall has an up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com