Power transformer overheating fusing protective device

A technology for power transformers and protection devices, applied in the direction of emergency protection circuit devices, electrical components, electrical component structure associations, etc., can solve problems such as burnt coils, high overcurrent insurance setting, and shortened life, and achieve the effect of avoiding burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

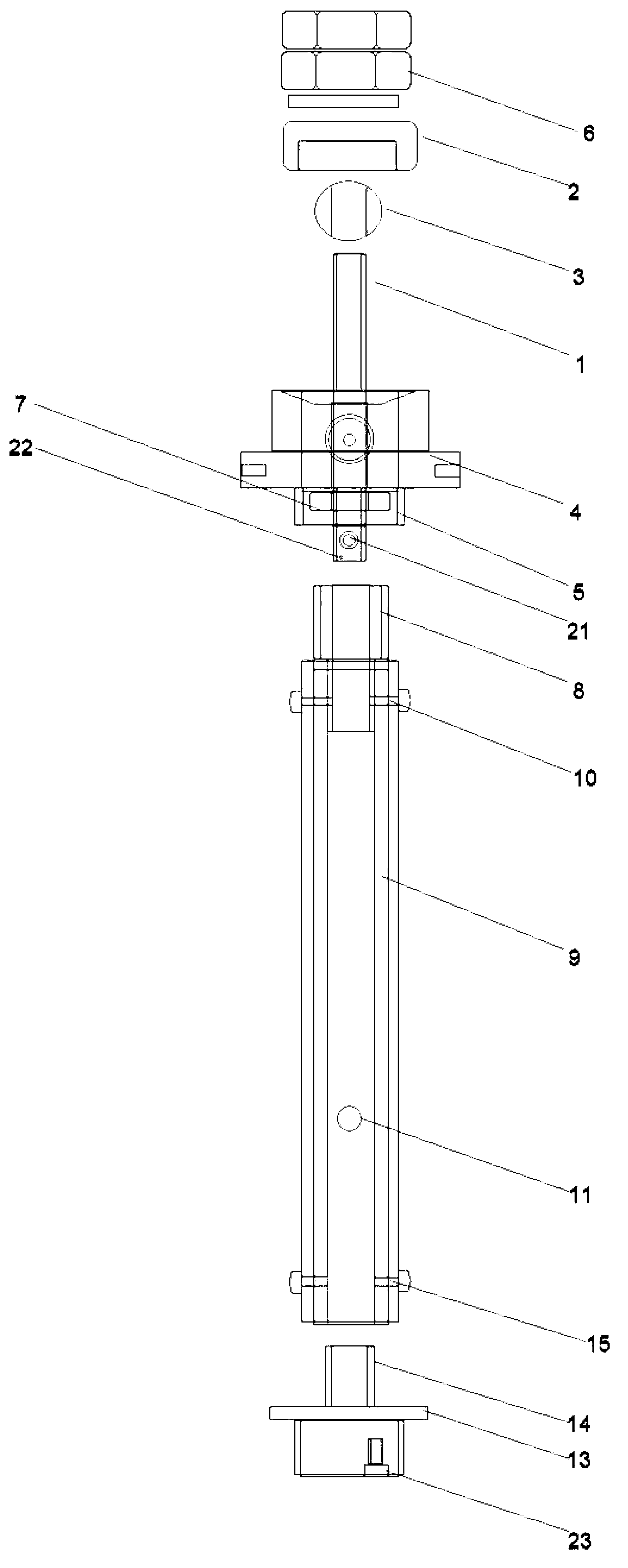

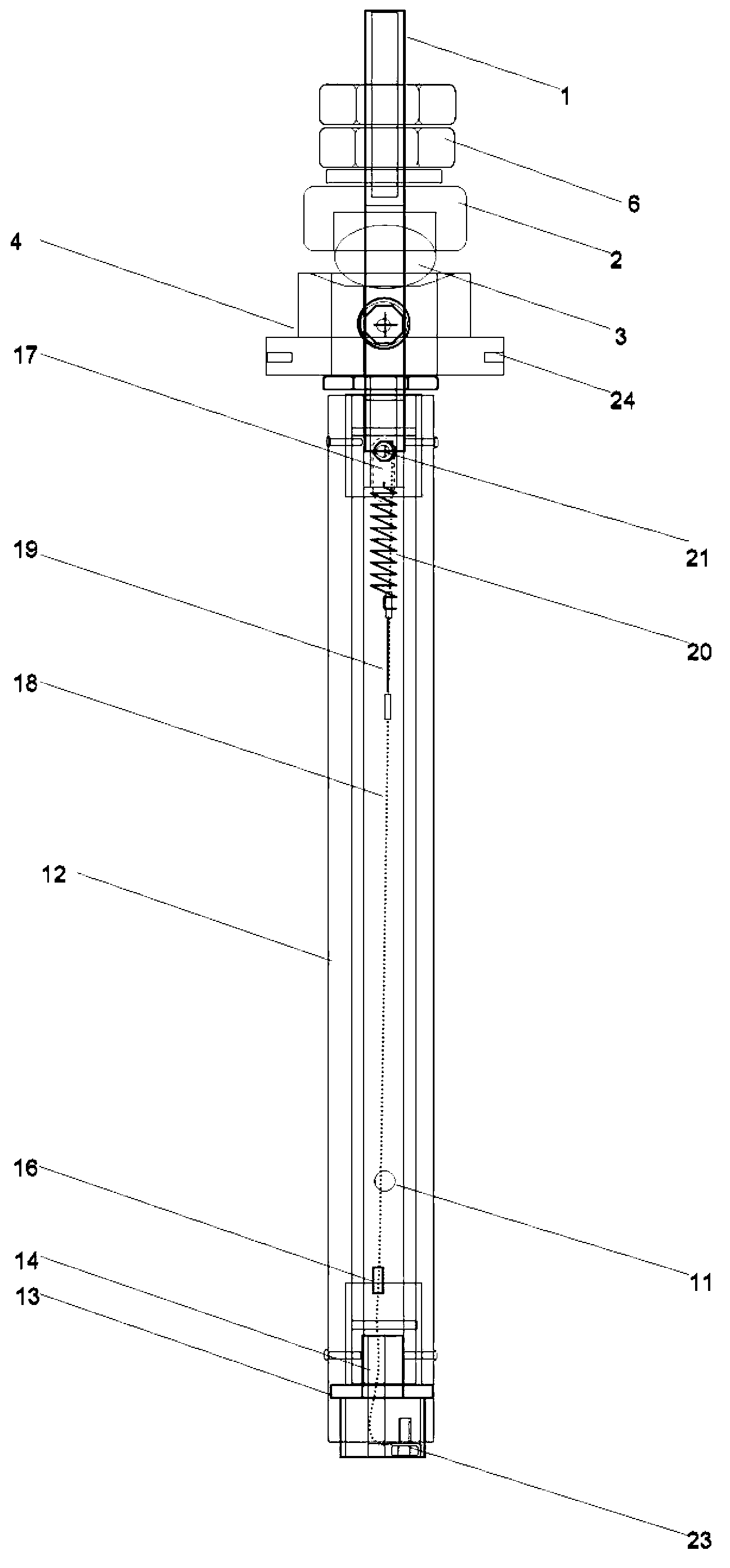

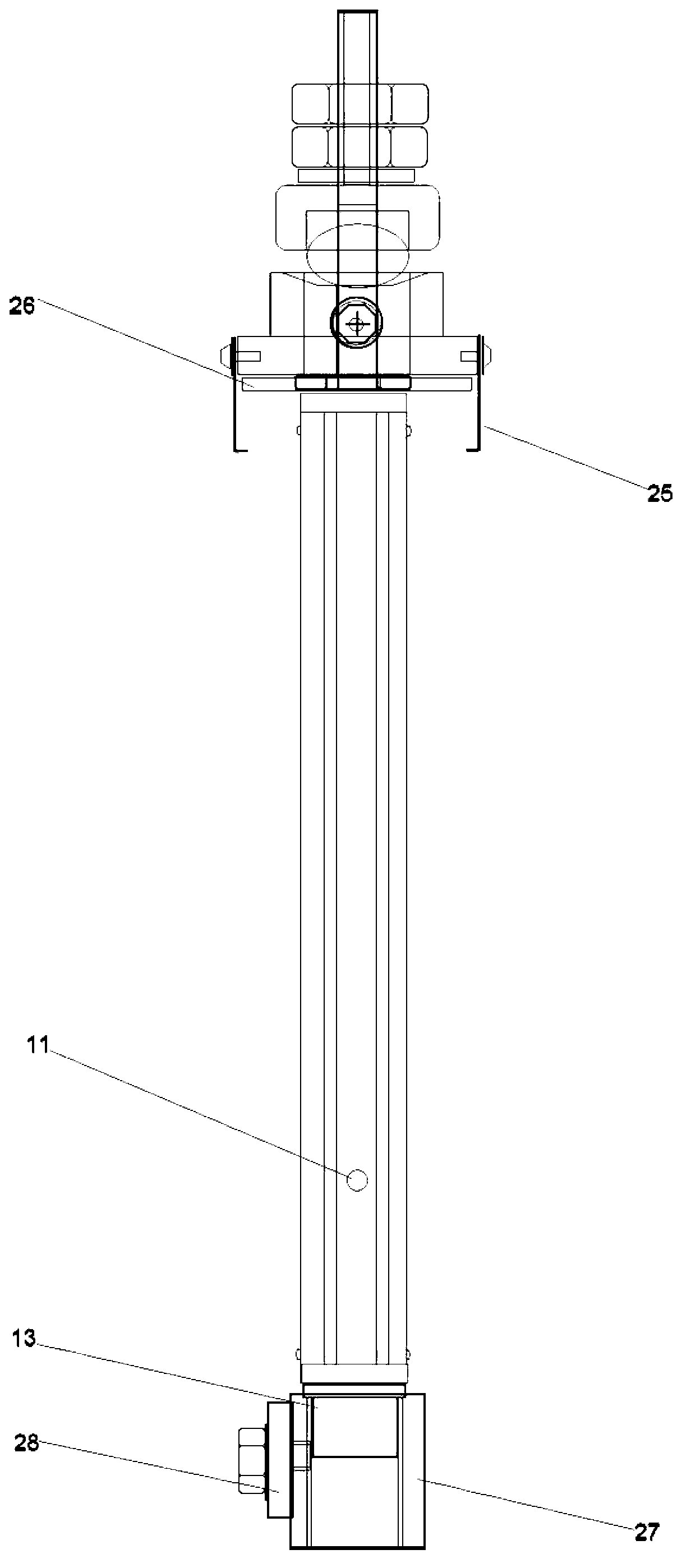

[0015] Below in conjunction with accompanying drawing, the present invention will be further described:

[0016] Power transformer overheating fuse protection device, including conductive rod 1, insulating tube 9 and wiring sleeve 29;

[0017] combine figure 1 : The conductive rod 1 is sequentially covered with a ceramic gland 2, a sealing rubber ball 3, a sleeve gland 4 and a fixed sleeve 5 from top to bottom, and the compression nut group 6 at the upper end of the ceramic gland 2 and the conductive rod 1 Screw connection and the screw connection of the fixed sleeve 5 and the locking fixing nut 7 to fasten each device on the conductive rod 1, the fixed sleeve 5 is screwed to the threaded side of the pup joint 8 through the internal thread provided at the lower end , the unthreaded side of the puppet 8 is inserted into the upper end of the insulating tube 9, and connected by rivets through the puppet connection hole 10 opened on the upper end of the insulating tube 9, the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com