tools for machining workpieces

A technology of tools and components, which is applied in the field of tools for metal workpieces, can solve problems such as mechanical deformation of workpieces, and achieve the effects of cheap manufacturing, simple structure, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

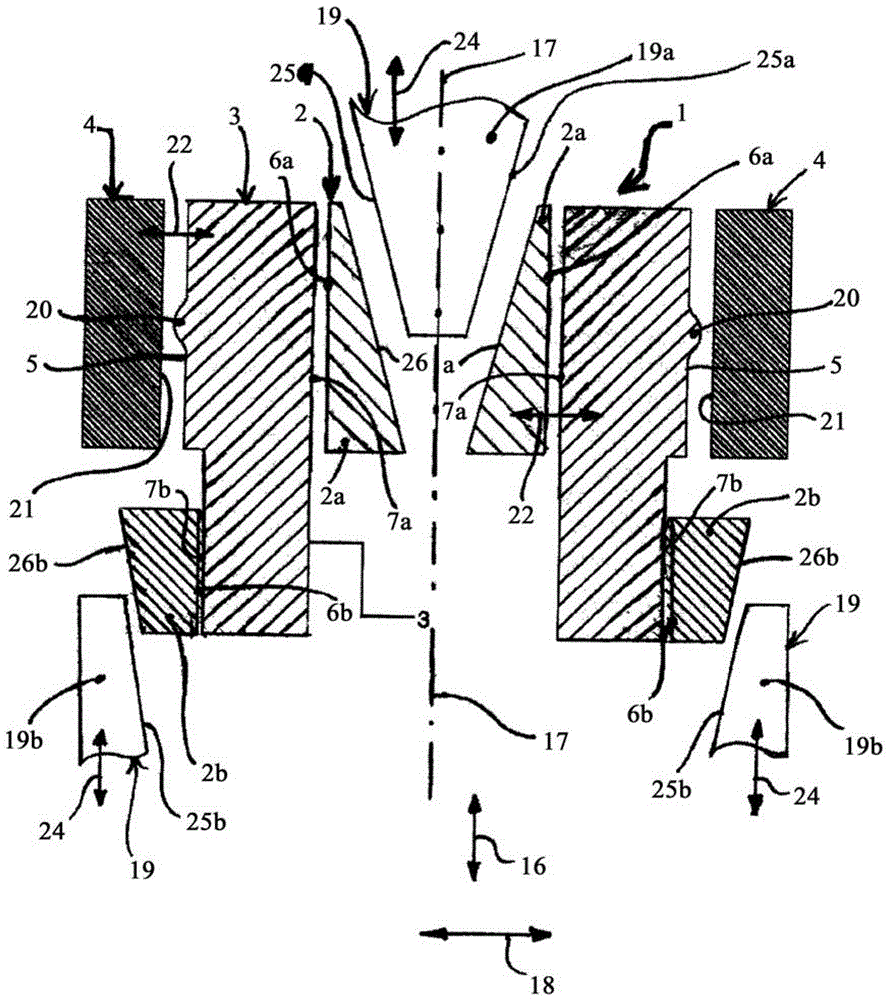

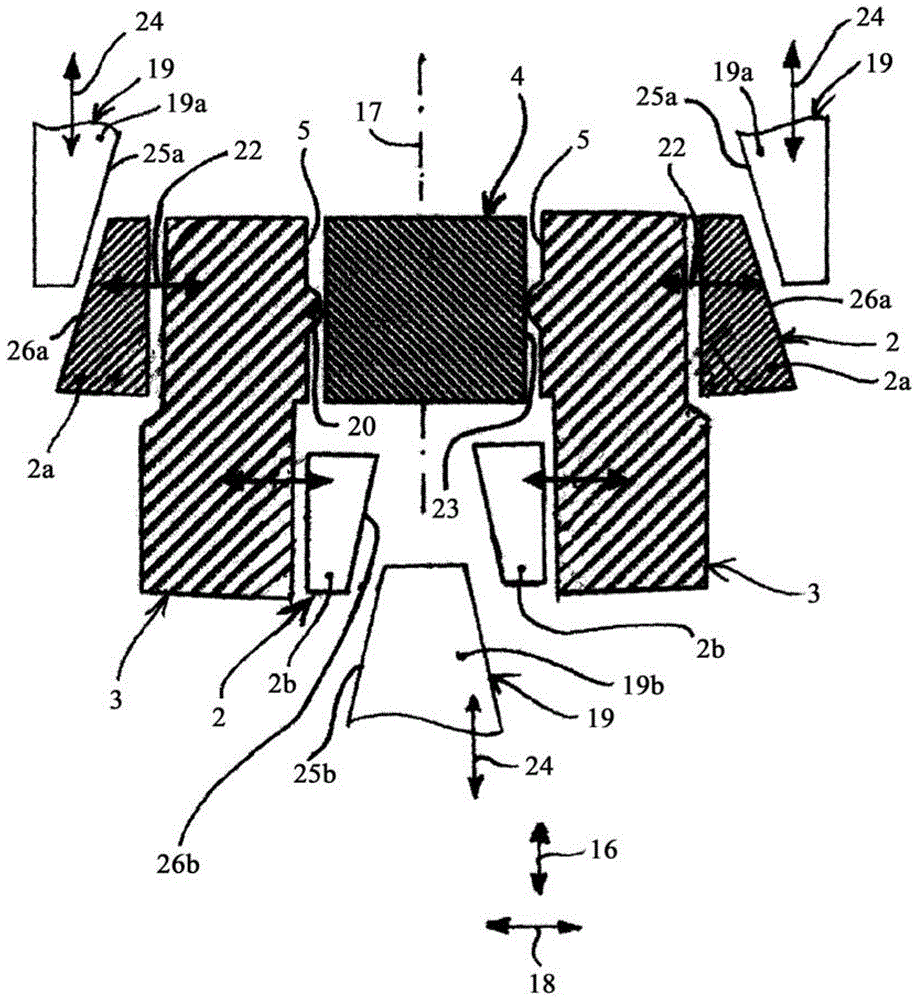

[0069] according to figure 1 , the tool 1 for forming has a transmission part 2 and a forming part 3 . The transmission part 2 comprises a first transmission part part 2a and a second transmission part part 2b. The two transmission element parts 2 a and 2 b are arranged at a distance from each other in the axial direction 16 of the tool 1 , ie along the central longitudinal axis 17 of the tool 1 . The radial extension of the profiled part 3 can vary in the radial direction 18 . For this purpose, the movement of individual or all transmission element parts 2 a , 2 b in radial direction 18 is controlled. by means of only figure 1 The movement control is carried out by corresponding drive members 19a, 19b schematically shown in .

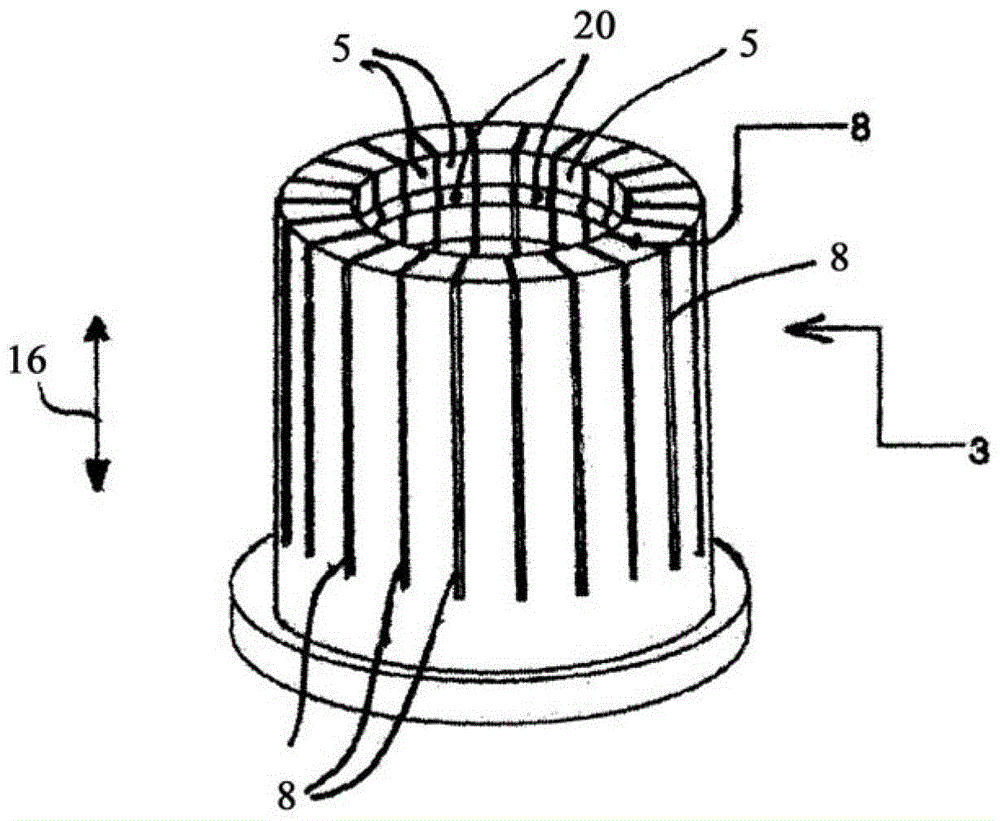

[0070] The profiled part 3 has a contact surface 5 with a profiled relief 20 for a provided radially inner surface 21 of the annular workpiece 4 that is to be profiled in the working direction 22 . The working direction 22 runs substantially in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com