Friction clutch

A technology of friction clutches and clutches, which is applied in the direction of friction clutches, clutches, mechanically driven clutches, etc., and can solve problems such as shortened service life, limited usability and usability, and reduced module accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

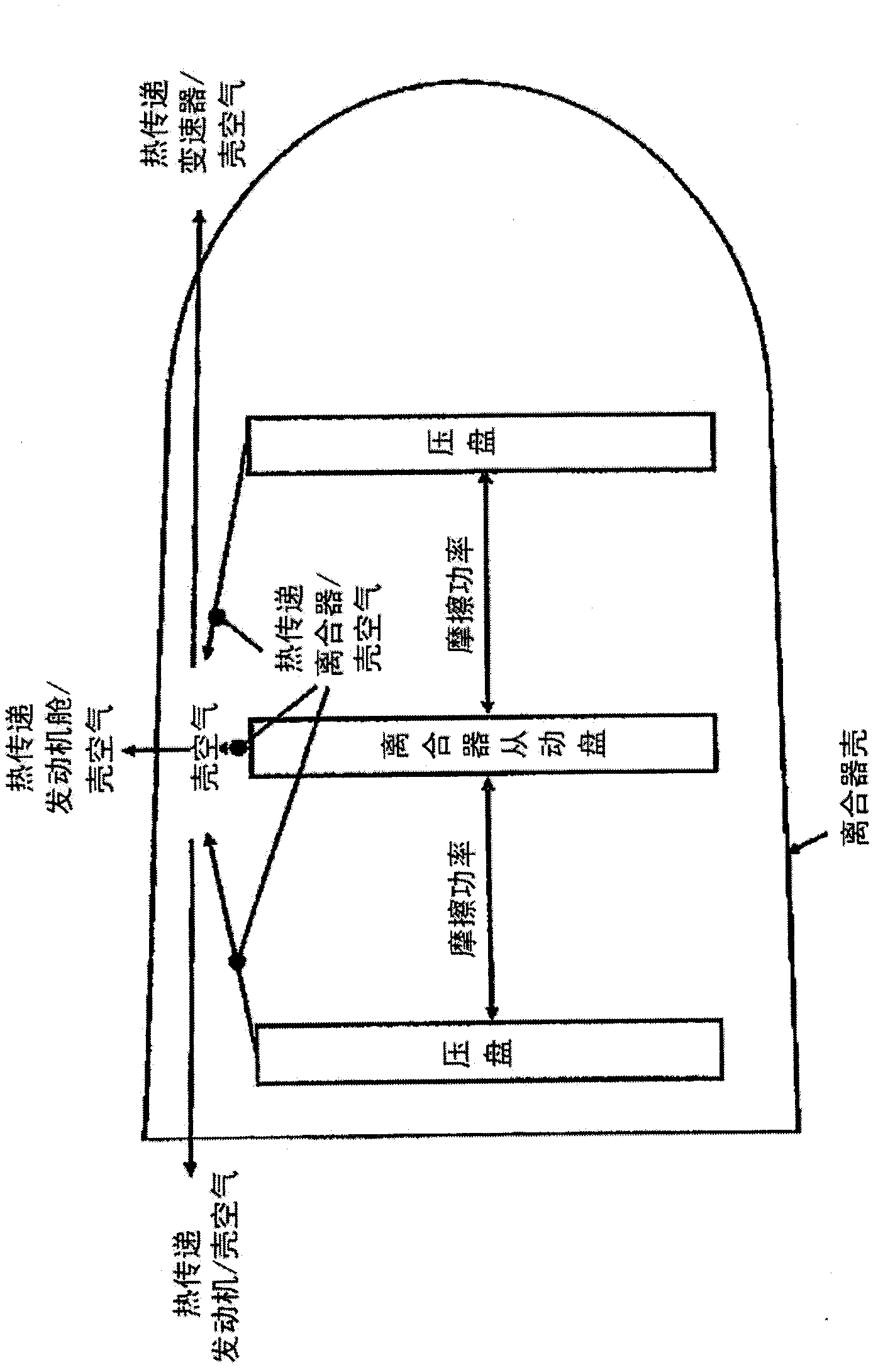

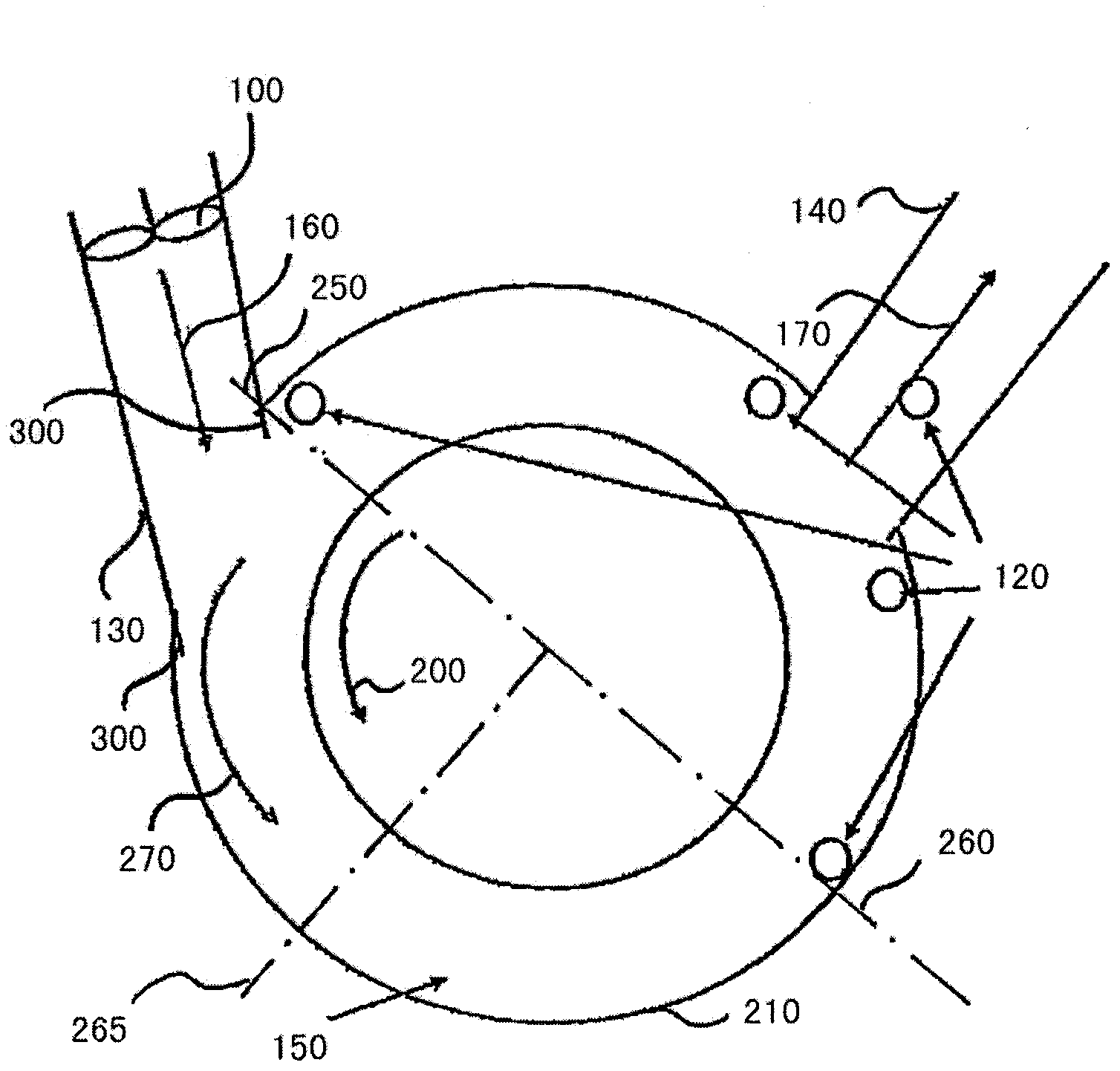

[0031] In order to determine the clutch temperature when active shell air cooling 100 is used, a temperature sensor 120 is arranged in shell air volume 150 . The reference numeral 120 designates not only the temperature sensor but also its position. figure 2 Some examples are given in . Particularly suitable sensor locations 120 can be determined from detection of the flow conditions within the clutch or clutch housing. Viewed from the intake channel 130 , in the flow direction 270 of the air conveyed through the intake channel 130 , favorable sensor positions 120 are the angular range between 90° (reference number 265 ) and 360° (reference number 250 ), especially 180° degrees (reference number 260 ) to 360 degrees (reference number 250 ), or the temperature sensor 120 is arranged in the air outlet channel 140 . An advantageous measuring position is therefore generally provided where the clutch housing interior air 150 has not yet been mixed with fresh air 160 , ie is not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com