Determination of media characteristics during filling level measurement

A material level measurement and material level technology, which is applied in the field of medium characteristics determination, and can solve the problems of inaccurate material level measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]If the same reference signs are used in different figures in the following description of the figures, they indicate identical or similar elements. However, identical or similar elements can also be identified by different reference signs.

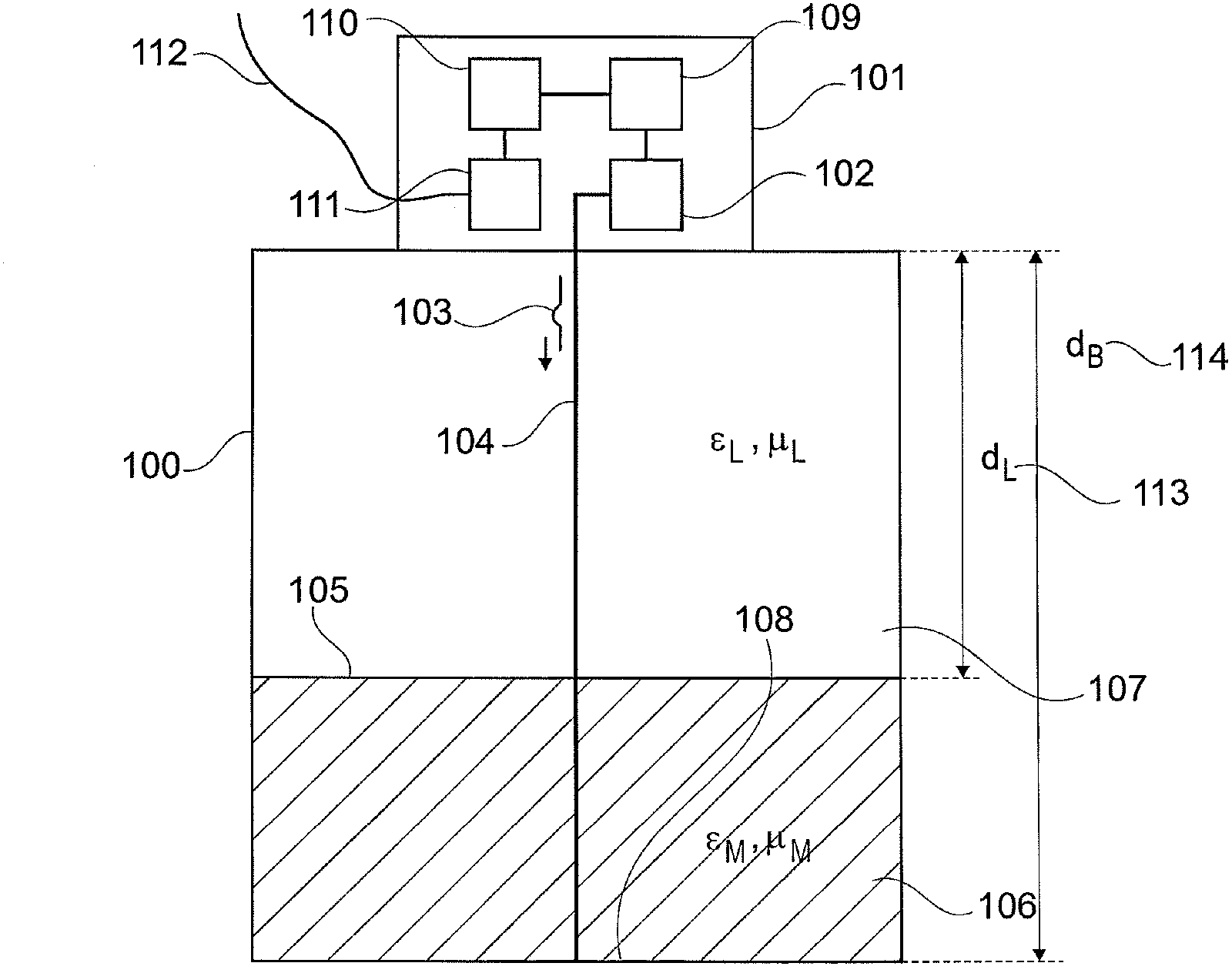

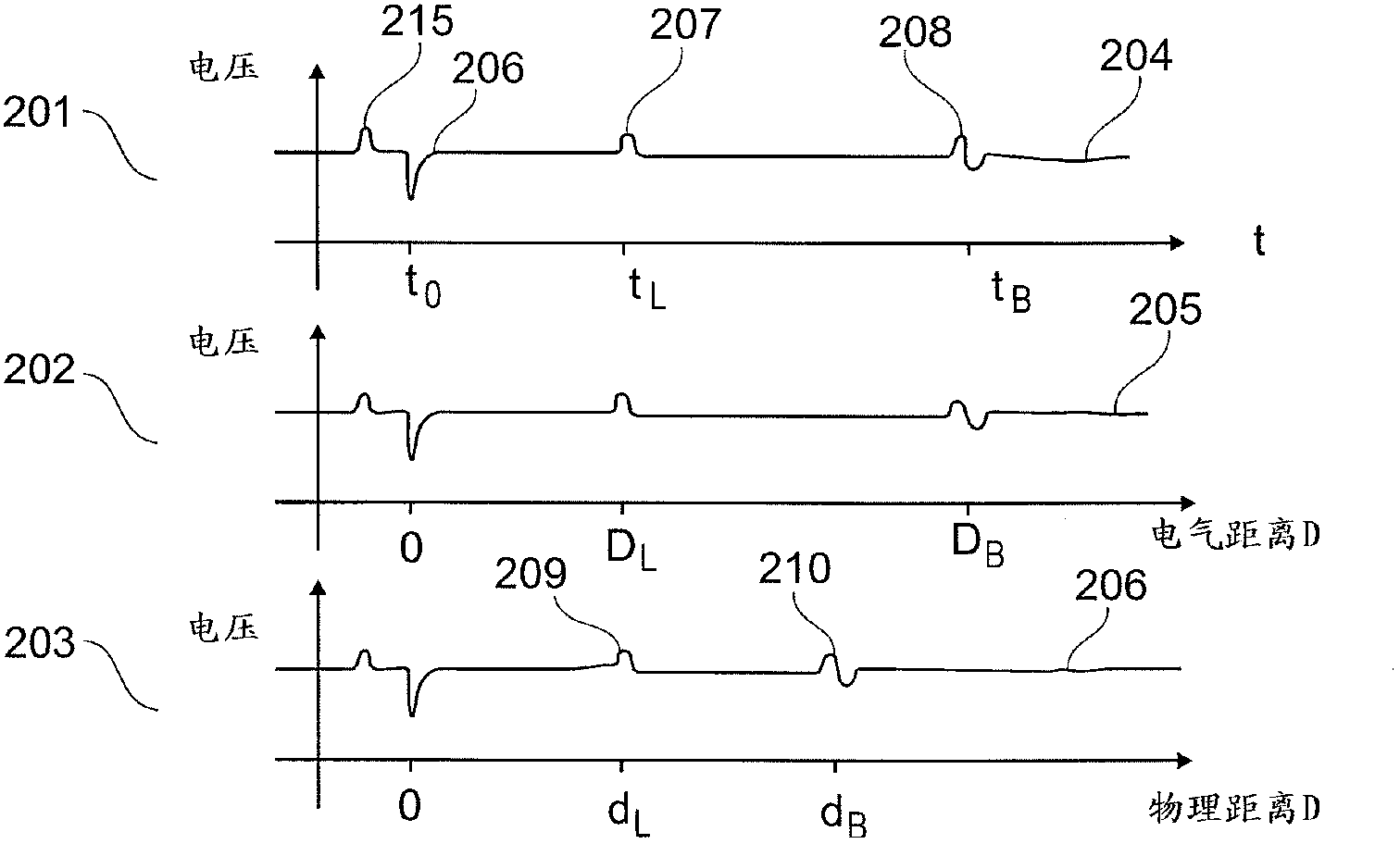

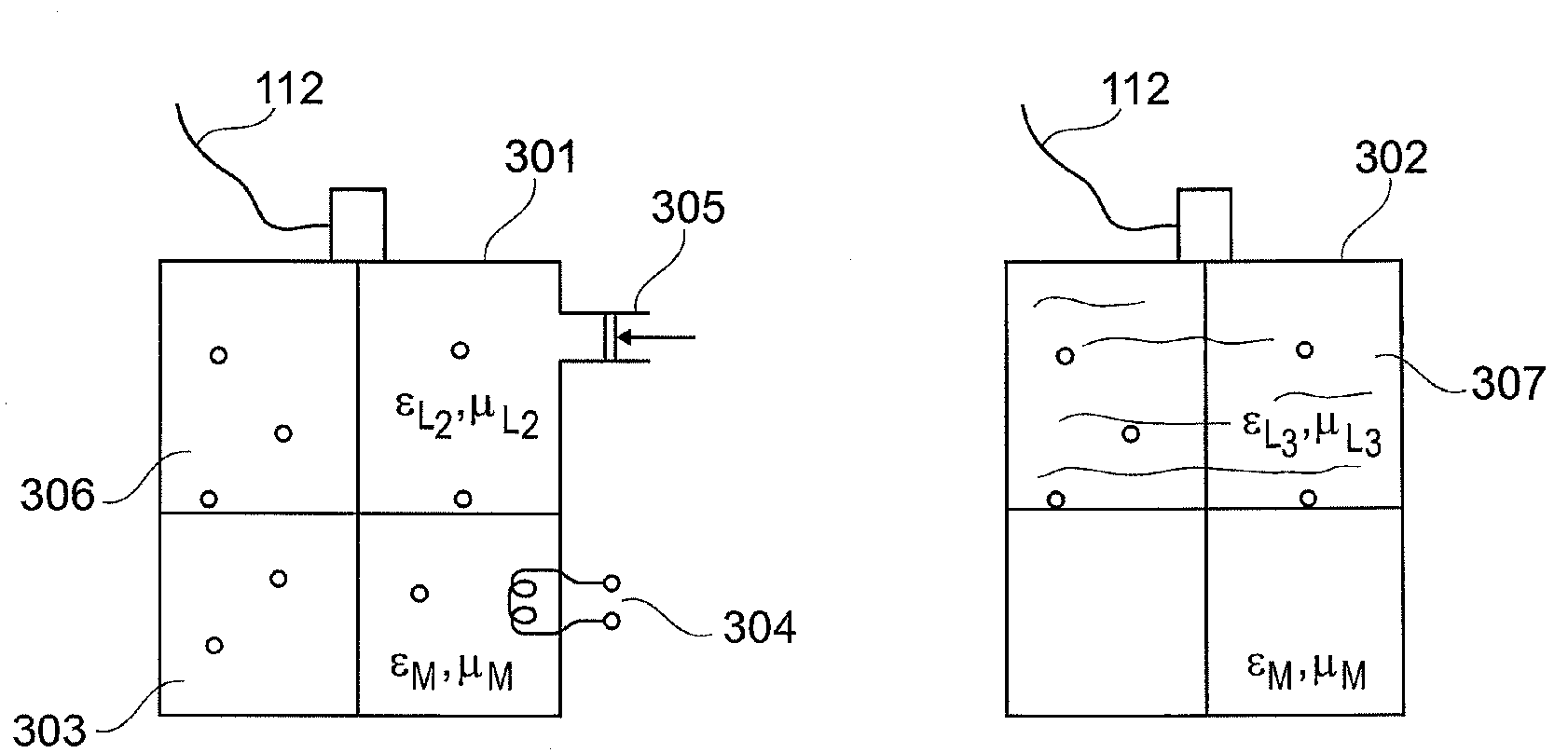

[0050] Common to all methods is that the signal used for the measurement is normally located in the area of influence of another medium, which shall subsequently be referred to as superimposed medium, on its way from the filling level measuring device to the filling surface and / or interface layer surface.

[0051] A superimposed medium is a medium or a mixture of different media which is located between the point of emission of the measuring signal of a level measuring device (for example an antenna of a filling level measuring device) and the surface of the medium to be measured or between the surface of the medium to be measured. Between the point of emission of the measuring signal of a level measuring device (eg an antenna of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com