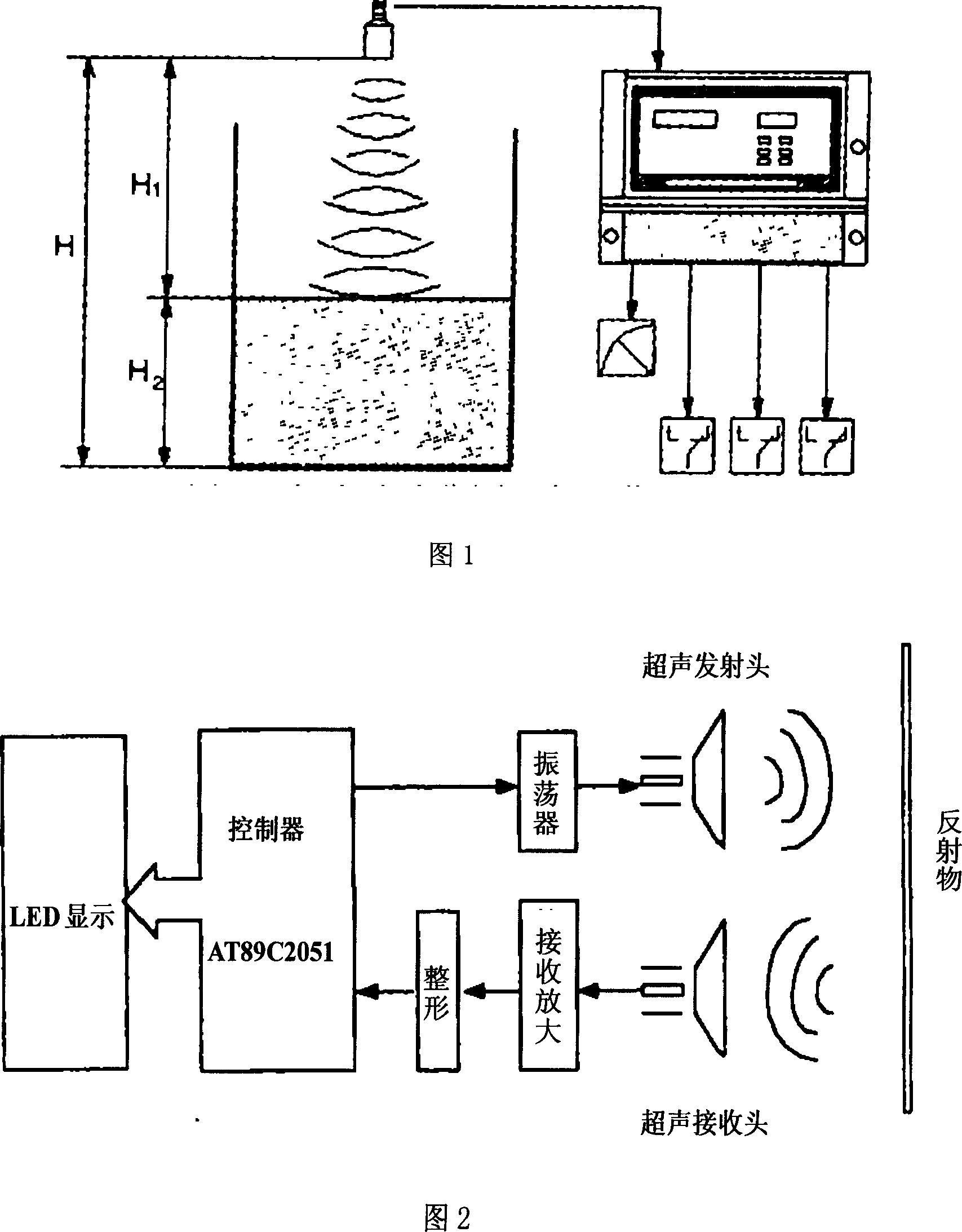

Device for ultrasonic measuring liquid level and method thereof

An ultrasonic measurement and ultrasonic technology, applied in the field of liquid level gauges, can solve problems such as inaccurate measurement, large errors, and measurement errors, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

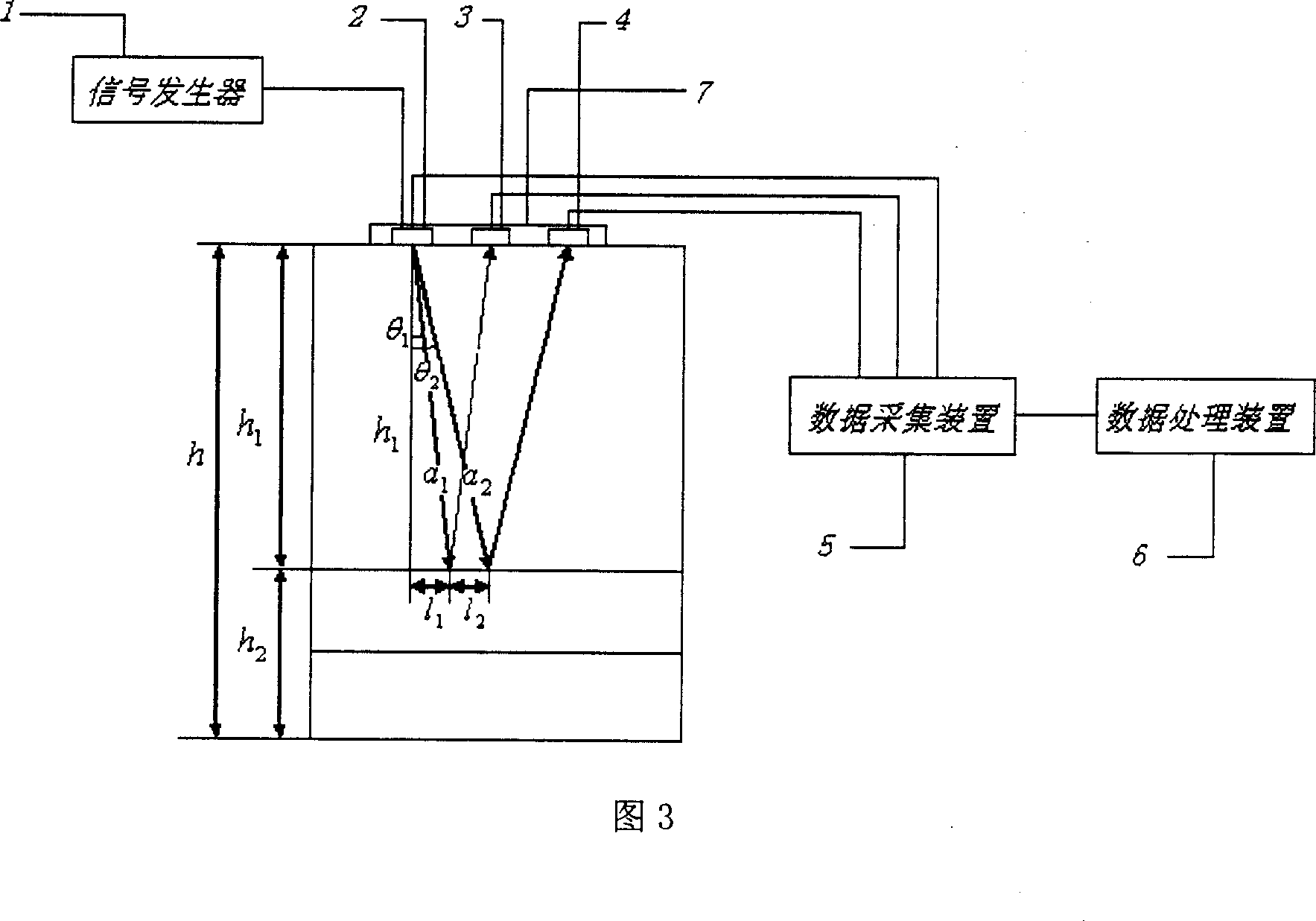

Method used

Image

Examples

Embodiment Construction

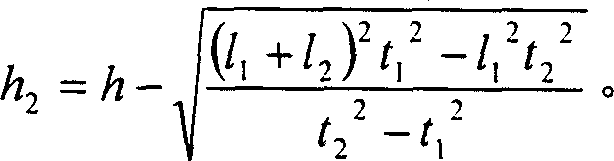

[0038] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0039] In the present invention, a plurality of probes are placed on the same plane above the liquid surface, one emits ultrasonic waves, and the rest receive the emitted ultrasonic waves. Due to the different positions of the receiving probes, the propagation paths of the received sound waves are different, that is, the propagation times are different. The data acquisition device is used to determine the propagation time of the signals received by each receiving probe, so as to determine the angular relationship between the propagating sound rays. Connect the connection lines between the probes and the propagation trajectory of the sound rays, etc., and the calculation of the height of the liquid level is equivalent to the calculation of the height of the triangle. The distance between the probes is a preset fixed value, that is, the base of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com