Pump block tilter

A technology for turning over machines and pump bodies, which can be applied to assembly machines, metal processing equipment, manufacturing tools, etc. It can solve problems such as damage to pump bodies, personnel damage, and low efficiency, and achieve increased assembly speed, reduced labor intensity, and reduced safety risks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

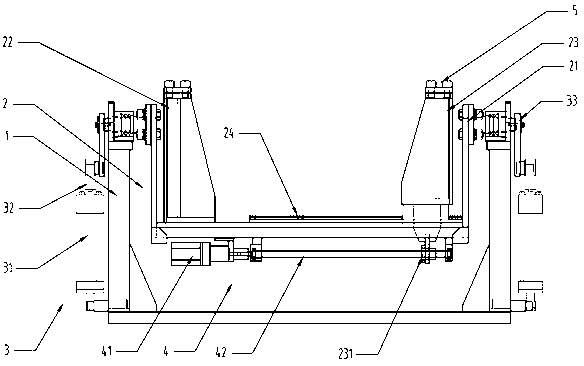

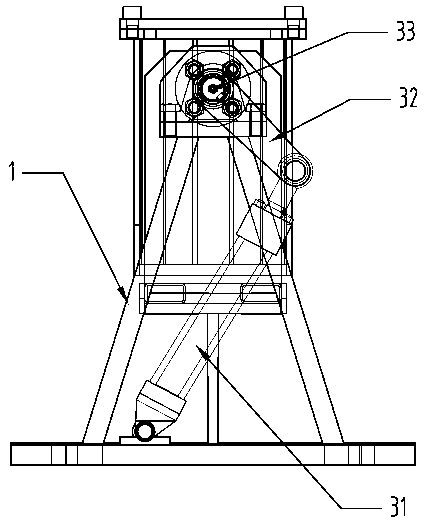

[0015] See figure 1 with figure 2 As shown, the present invention provides a pump body turning machine for clamping and turning the pump body. In particular, the pump body turning machine includes a bracket 1, a clamping unit 2 and a turning unit 3. The clamping unit 2 uses the bracket 1 as The fulcrum is axially connected with the turning unit 3, and the clamping unit 2 fixes and clamps the pump body and is driven by the turning unit 3. The clamping unit 2 turns 360° under the driven state to achieve the effect of the pump body turning.

[0016] Among them, the clamping unit 2 includes a bracket 21, a clamping column 22, a mobile clamping column 23 and a sliding rail 24, the clamping column 22 and the sliding rail 24 are fixedly attached to the bracket 21, and the mobile clamping column 23 is movably attached On the slide rail 24, the pump body is slidably clamped by moving the clamping column 23. Both the clamping column 22 and the moving clamping column 23 are provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com