Equipment for one-time pile forming into rock of screw pile driver and pile forming method

A screw pile driver and pile forming technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of easy collapse of the pile hole wall, poor drilling quality and high drilling cost, shorten the construction period and improve the pile formation. Quality, effect of simplified pile-forming process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

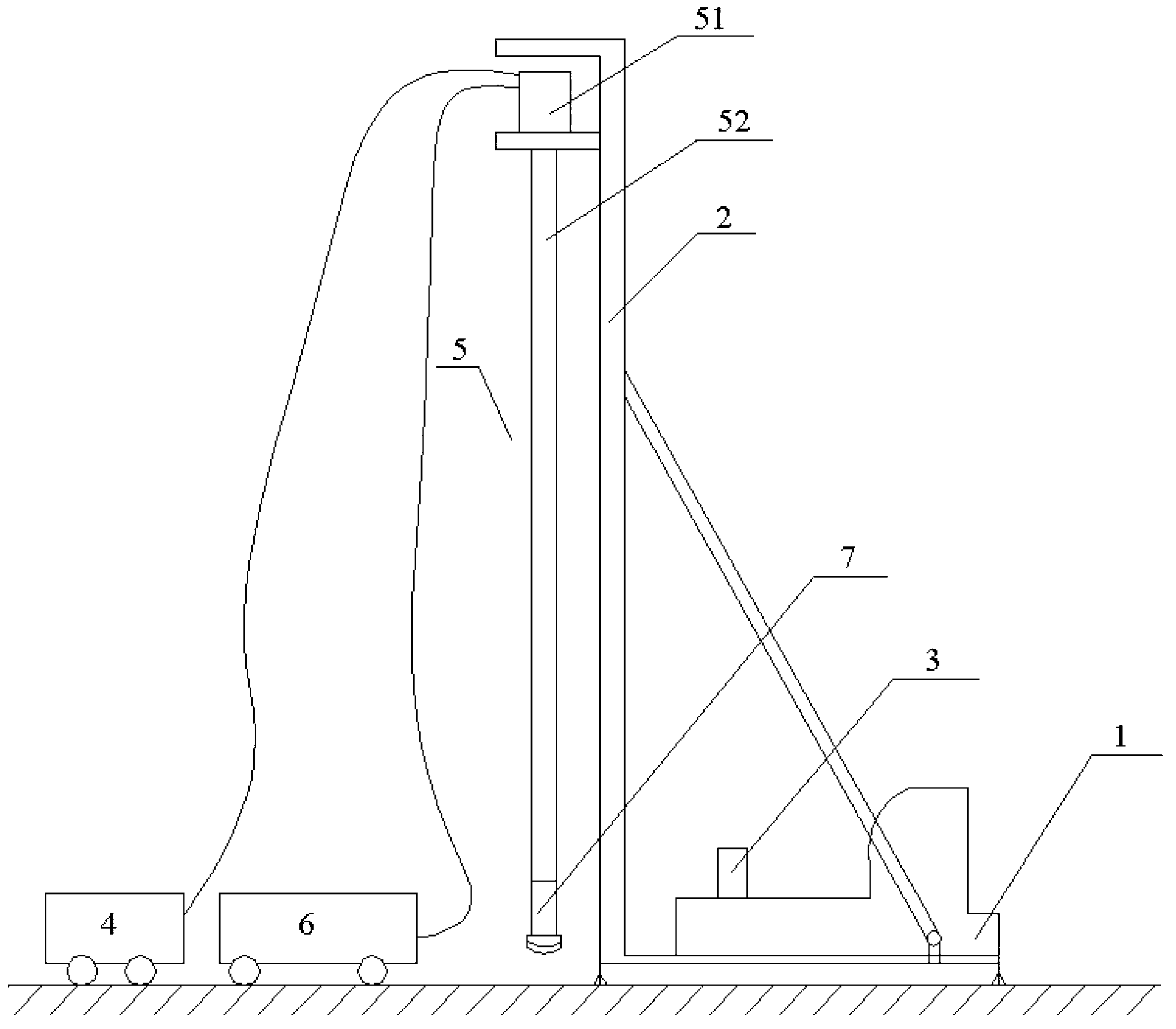

[0040] One-time pile forming equipment for screw pile machine into rock, its structure is as follows figure 2 Shown; comprise machine base 1, guide column 2 is installed on the machine base 1, the side of guide column 2 is provided with hammer chisel mechanism 5 and drive motor 3 and air compressor 4 that provide power for hammer chisel mechanism; Wherein hammer chisel The mechanism 5 includes a rotary machine tool 51 , an auger rod 52 and a pneumatic down-the-hole hammer 7 .

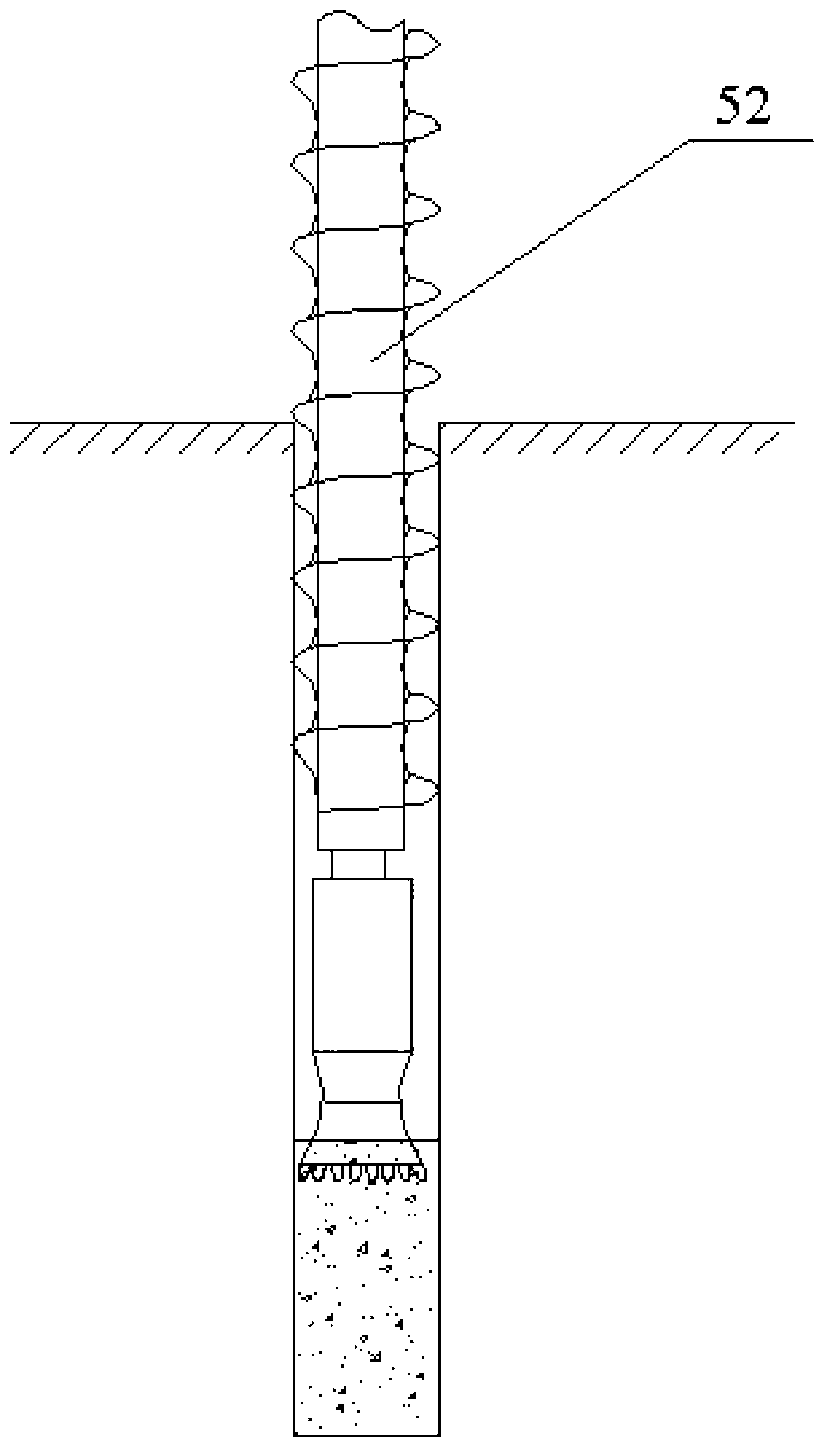

[0041] Among them, the auger drill rod is a hollow drill rod with convex helical blades, and its structure is as follows: image 3 As shown, the outer diameter of the helical blade on the auger rod 52 corresponds to the inner diameter of the pile hole to be processed; that is, the outer edge of the convex helical blade is in contact with the wall of the pile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com