System and method for efficiently generating power from steam

A power generation system and water vapor technology, which is applied in steam applications, steam engine devices, machines/engines, etc., can solve the problems of large cooling power consumption, waste of latent heat of water vapor, and no water vapor utilization, and achieve effective utilization and improved utilization. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

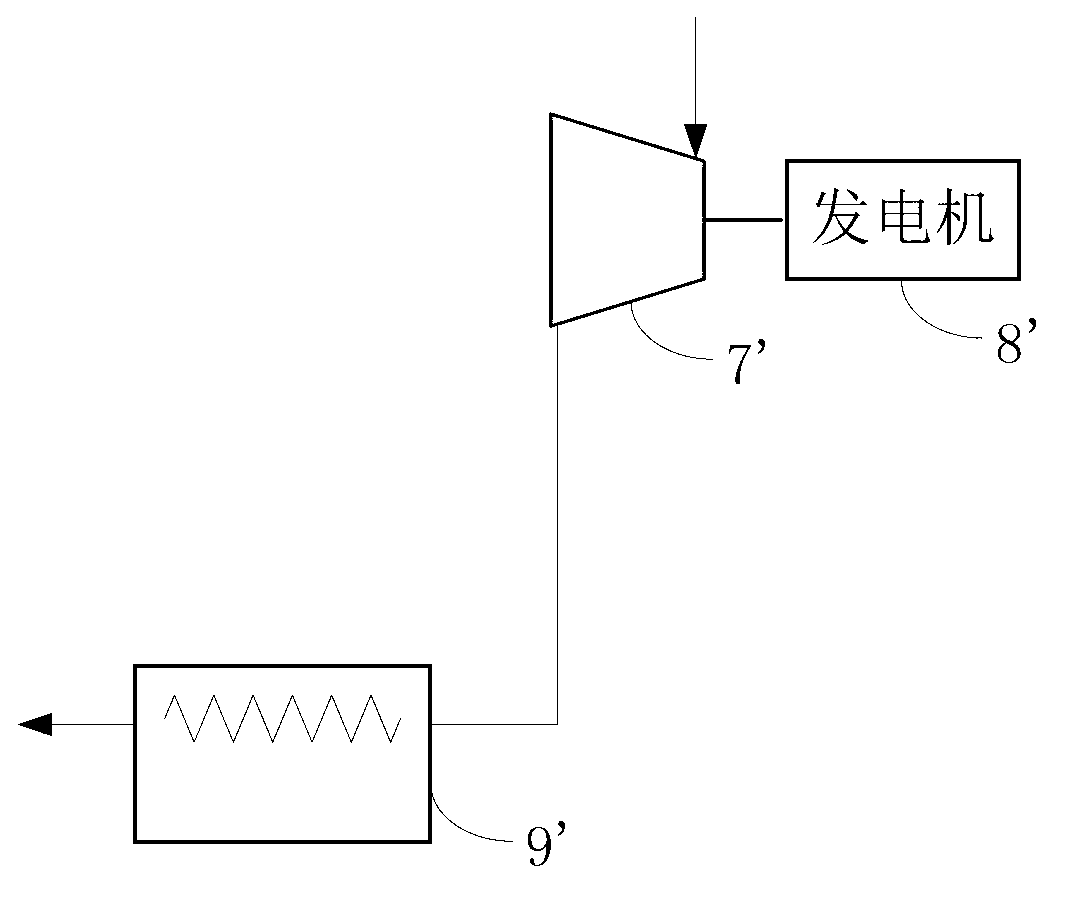

Image

Examples

Embodiment 1

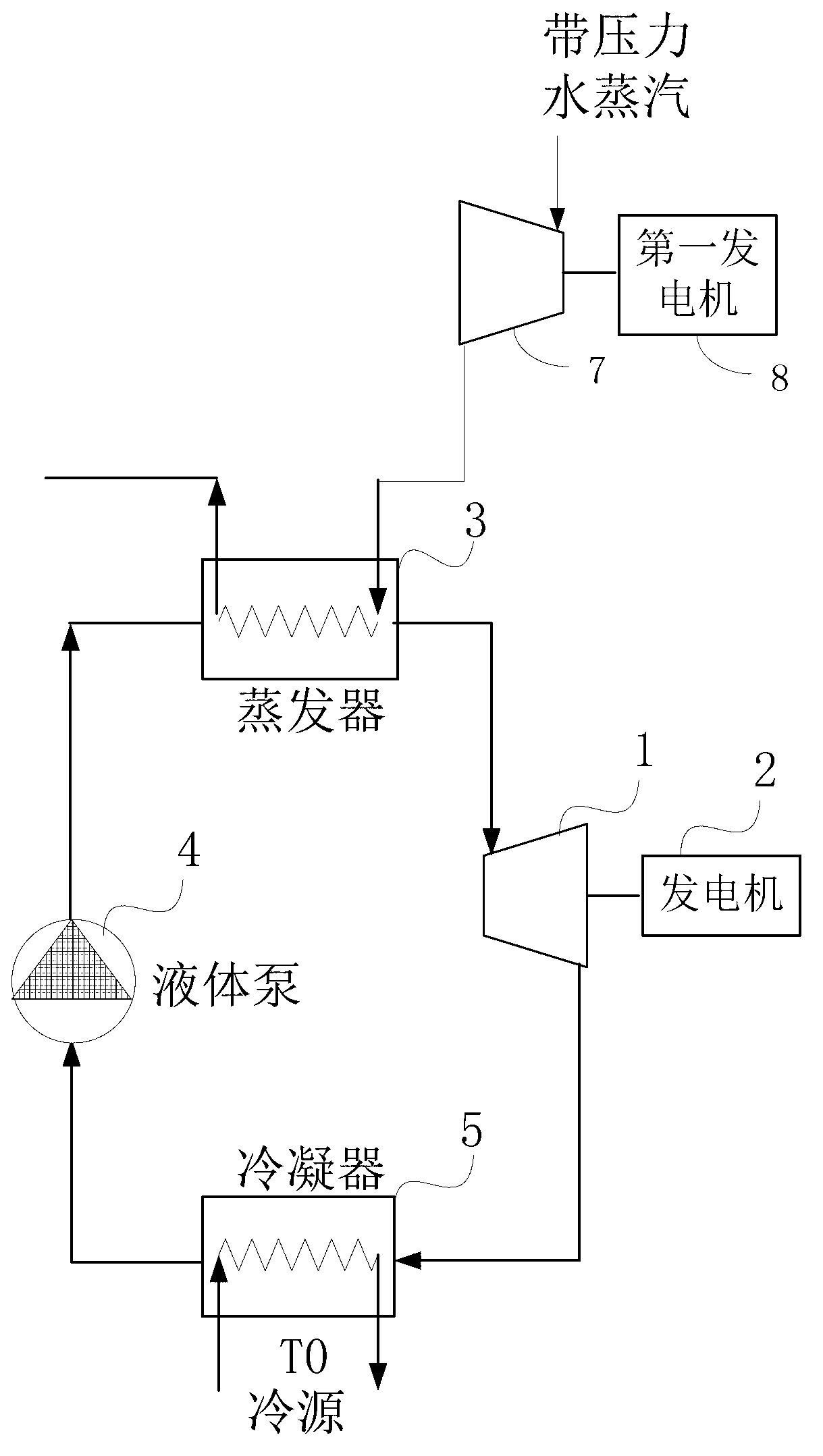

[0034] see figure 2 , the present invention discloses a high-efficiency power generation system for water vapor. The system includes a first power generation system and a second power generation system. The first power generation system includes one or more first power generation devices, and the second power generation system includes one or more An organic Rankine cycle system. In this embodiment, the first power generation system includes a first power generation device, and the second power generation system includes an organic Rankine cycle system.

[0035] The first power generation device includes a steam expander 7, a first generator 8 connected to the steam expander 7, steam with pressure (steam is superheated or saturated steam, usually residual pressure steam, Its pressure is generally required to be greater than or equal to 2 barG, that is, the gauge pressure per square centimeter is 2 kg) connected to the inlet of the steam expander 7, and the steam expander 7 u...

Embodiment 2

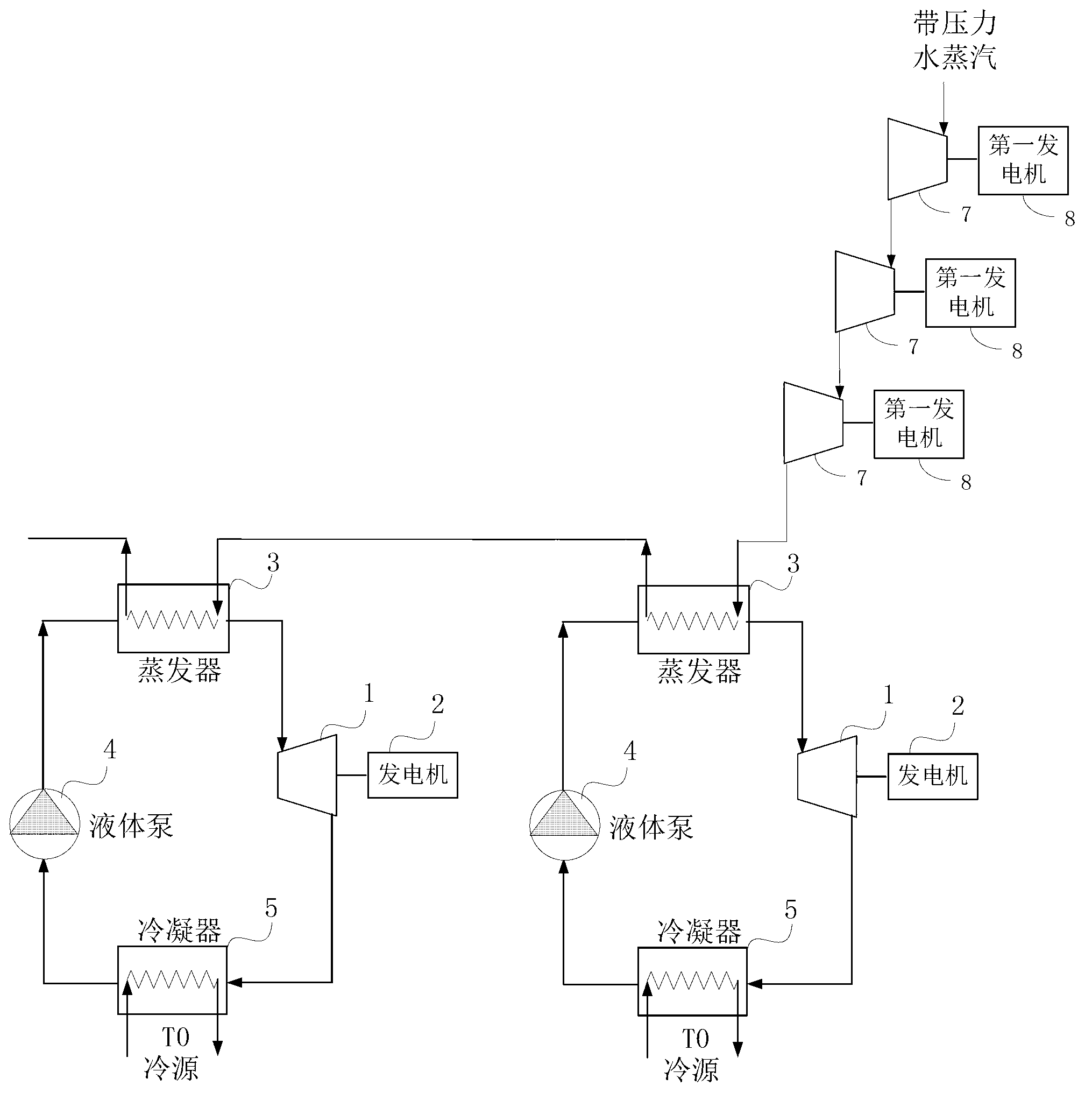

[0041] see image 3The difference between this embodiment and Embodiment 1 is that in this embodiment, the first power generation system includes a plurality of first power generation devices connected in series, and the second power generation system includes a plurality of organic Rankine cycle systems connected in series.

[0042] The steam with pressure is connected to the inlet of the steam expander 7 of the first power generation device as the first stage, and the water vapor is discharged from the outlet of the steam expander 7 of the first power generation device as the last stage, and enters the second power generation system, The pressure of the water vapor discharged from the last-stage steam expander 7 is greater than or equal to -0.6 barG and less than or equal to 1 barG.

[0043] The evaporators 3 of each organic Rankine cycle system are sequentially connected in series to form multi-stage expansion; except for the last stage, the pressure of the water vapor disc...

Embodiment 3

[0057] see Figure 4 , The difference between this embodiment and Embodiment 1 is that in this embodiment, the first power generation system includes a plurality of parallel first power generation devices, and the second power generation system includes a plurality of organic Rankine cycle systems, some of which are organic Rankine cycle systems. Ken circulation system in parallel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com