Gear shifting method using economy shift schedule of blade electric vehicle

A pure electric vehicle and shifting regularity technology is applied in the shifting field that utilizes the economical shifting regularity of pure electric vehicles. It can solve the problems that are rarely studied and affect the performance of the whole vehicle, so as to reduce the number of charging times, prolong the life, The effect of saving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. In order to realize the optimal economical shift control, it is necessary to first obtain the optimal economical shift schedule curve:

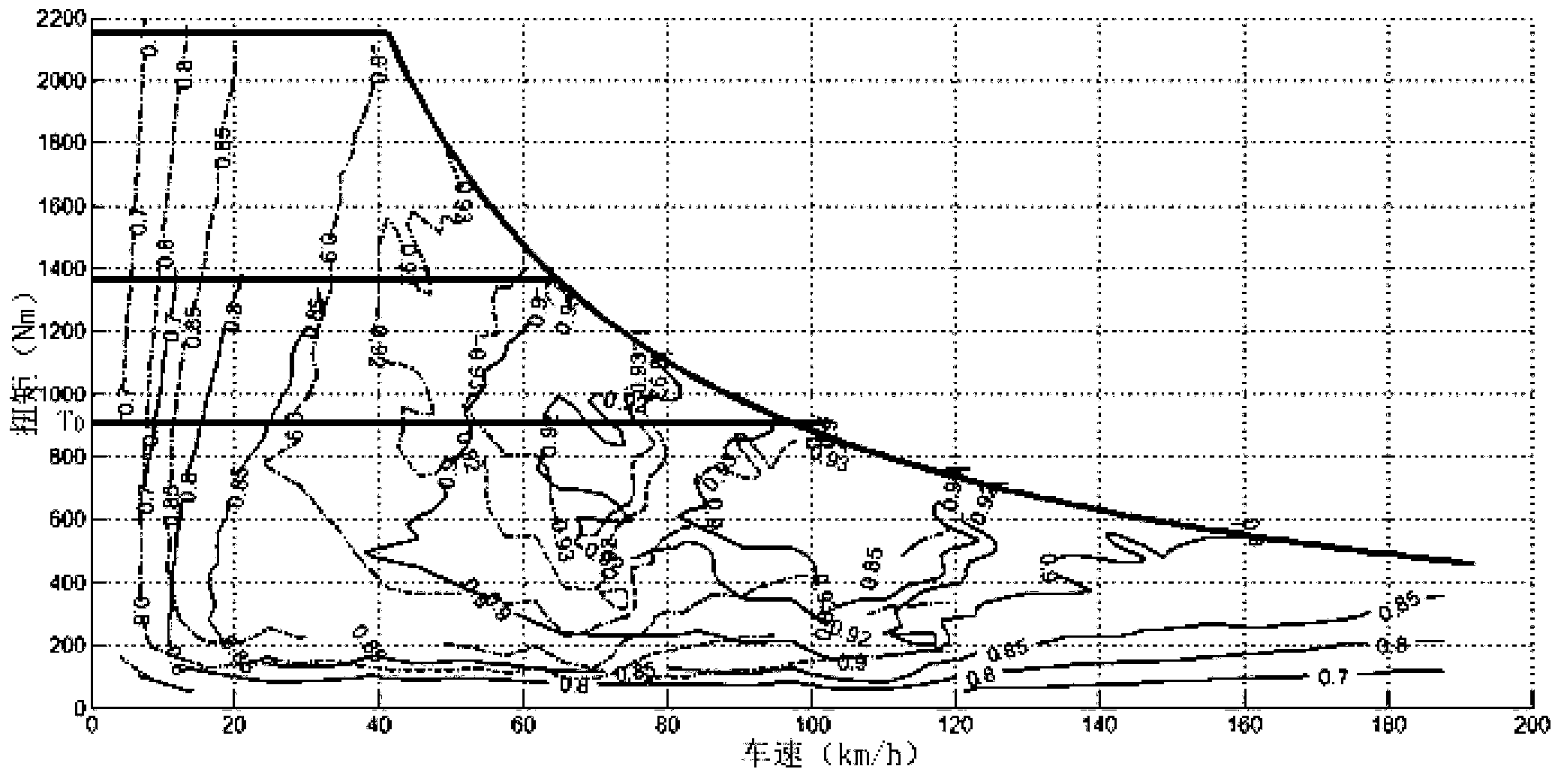

[0020] 1. Draw the driving characteristic curve and efficiency relationship graph of the motor at the first gear and the second gear on the same graph, such as figure 1 As shown in , take the vehicle speed as the abscissa, and the torque at the output end of the gearbox as the ordinate;

[0021] 2. Draw a horizontal line of constant driving force torque T0 in the overlapping area of the 1st gear and 2nd gear efficiency diagram in the figure, that is, when the output driving force is T0, there are two choices of 1st gear and 2nd gear;

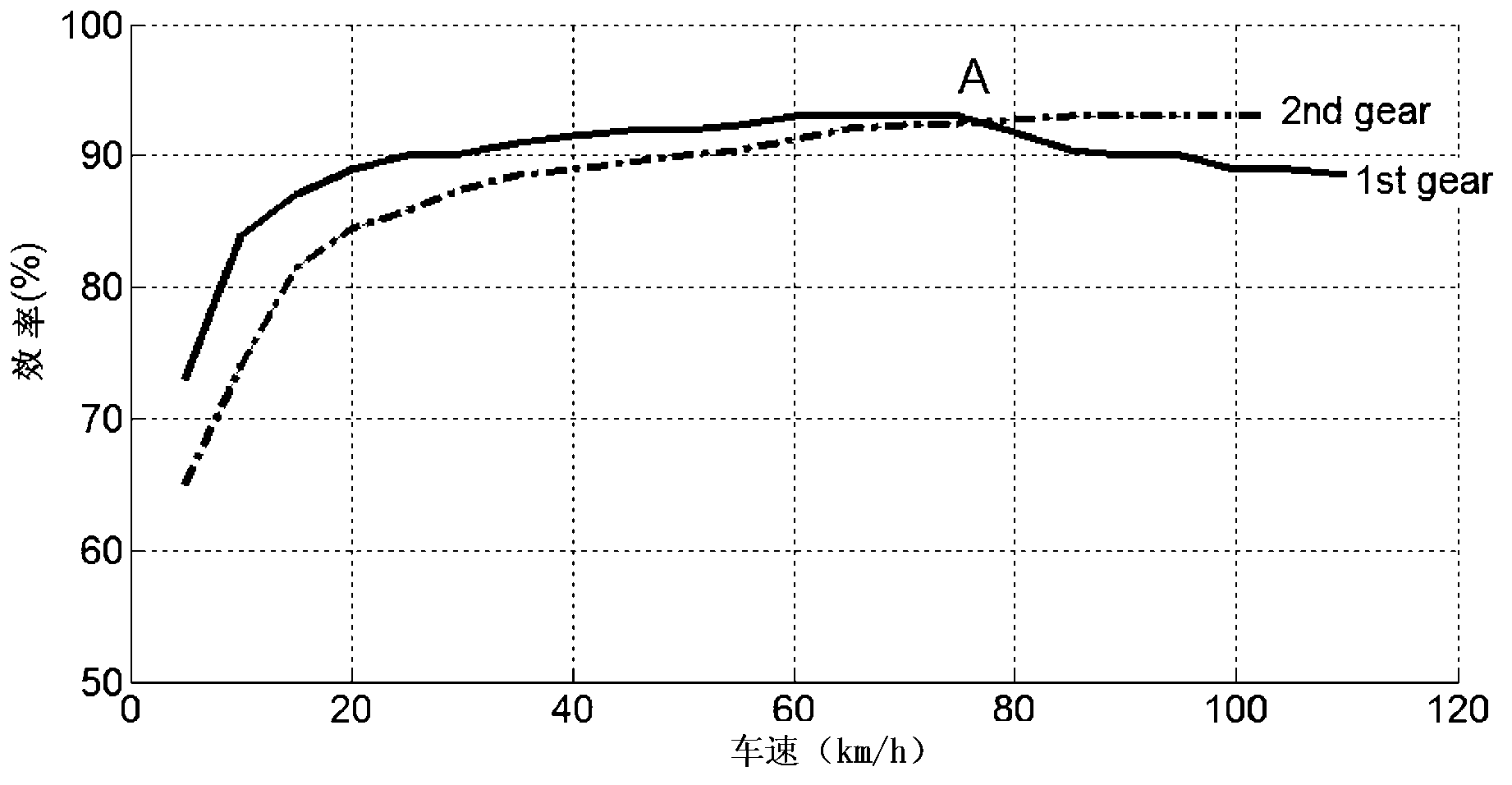

[0022] 3. Draw the efficiency value curves corresponding to the traction force T0 at different speeds of the 1st gear and 2nd gear in the same graph, as shown in figure 2 As shown, the intersection point A of the two curves, that is, at the vehicle speed before point A, the driving motor efficienc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com