Battery and battery pack

A battery and cell technology, applied in battery pack components, secondary batteries, circuits, etc., can solve the problems of short service life, reduced service life, poor sealing performance, etc. Group Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

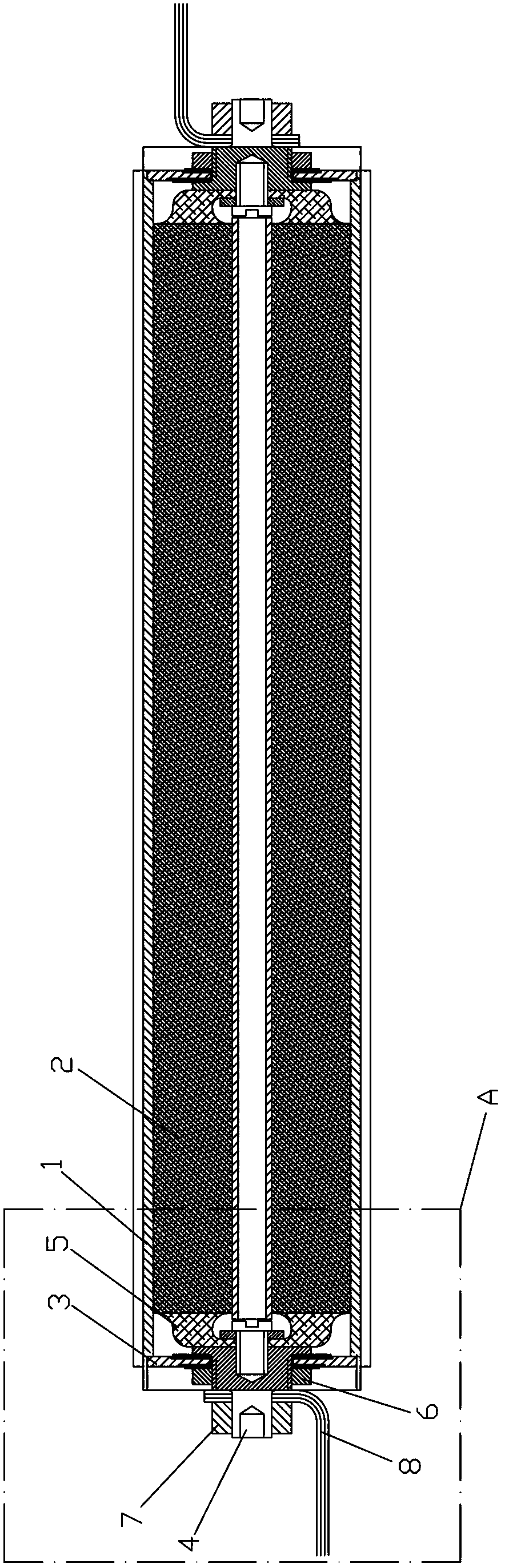

[0051] Embodiment 1: as Figure 1-4 As shown, the battery includes a casing 1 and a cell 2 , the casing 1 is cylindrical, and the casing 1 contains the cell 2 . Openings are formed at both ends of the casing 1 to lead out the positive and negative electrodes of the battery respectively. The structures of the two ends are the same or symmetrical, and the structure of one end will be described below.

[0052] The opening of the housing is covered by the end cover 3, the middle part of the end cover 3 passes through the pole 4, and the two are sealed and fitted. The inner side of the pole 4 is connected to the cell 2 through the pole lug 5 , the pole 4 and the pole lug 5 are connected by bolts, and the outside of the pole 4 is screwed to the end cover 3 by the nut 6 . The outer end of the pole 4 is also connected to the conductive strip 8 through the nut 7 .

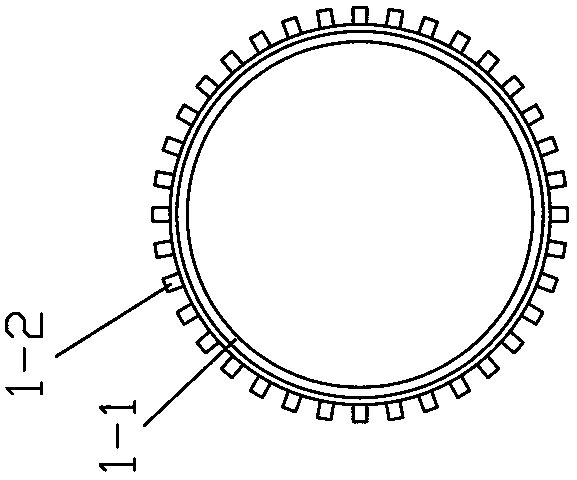

[0053] The two ends of the housing 1 respectively form an annular notch 11 along the inner wall, which is used for embe...

Embodiment 2

[0057] Embodiment 2: as Figure 8-11 As shown, the battery includes a casing 1, which is cylindrical, and contains an electric cell 2 inside the casing 1, and the middle part of the electric cell 2 supports an inner support tube 3 along the axial direction. Openings are formed at both ends of the casing 1 to lead out the positive pole and the negative pole of the battery respectively. The structures of the two ends of the battery are the same or symmetrical, and the structure of the negative pole will be described in detail below.

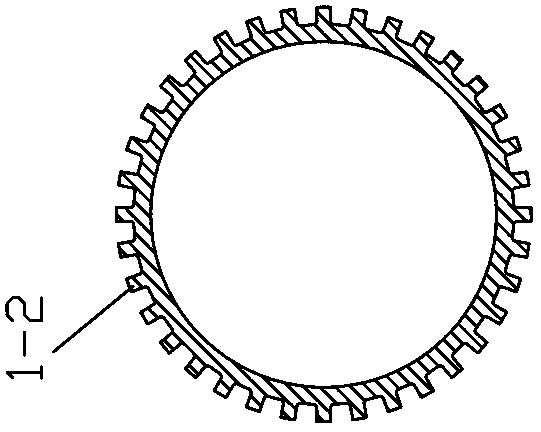

[0058]An annular notch 1 - 1 is formed along the inner wall at the end of the housing 1 , which is used for sealing and matching with the end cap 12 . The outer wall of the housing 1 is uniformly distributed with heat dissipation ribs 1-2 along the height direction, so that the housing can dissipate heat easily.

[0059] The end cap 12 is made of a circular aluminum alloy, and the outer periphery of the end cap 12 is sheathed with an insulating se...

Embodiment 3

[0069] Embodiment 3: as Figure 12 As shown, the open end of the shell 1 is covered with a threaded ring 18 , and the threaded ring 18 is welded with the outer wall of the shell 1 to form a welded part 19 of a circle.

[0070] The outer diameter of the port of housing 1 is smaller than the outer diameter of end cap 12, and the outer diameter of end cap 12 is corresponding to the outer diameter of threaded ring 18, and the port of housing 1 is covered with end cap 12, and then screwed with nut 17 and threaded ring 18. Tightly fix the end cap 12 , and the outer wall of the housing end in contact with the end cap 12 is sleeved with a sealing ring 16 .

[0071] Other content of this embodiment can refer to Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com