Energy recycling system for a construction apparatus

A technology of energy regeneration and variable flow, which is applied to fluid pressure actuation devices, fluid pressure actuation system components, earth movers/shovels, etc., and can solve the problem of deterioration of stick extension operation and inability to supply sticks Oil cylinder and other problems, to achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

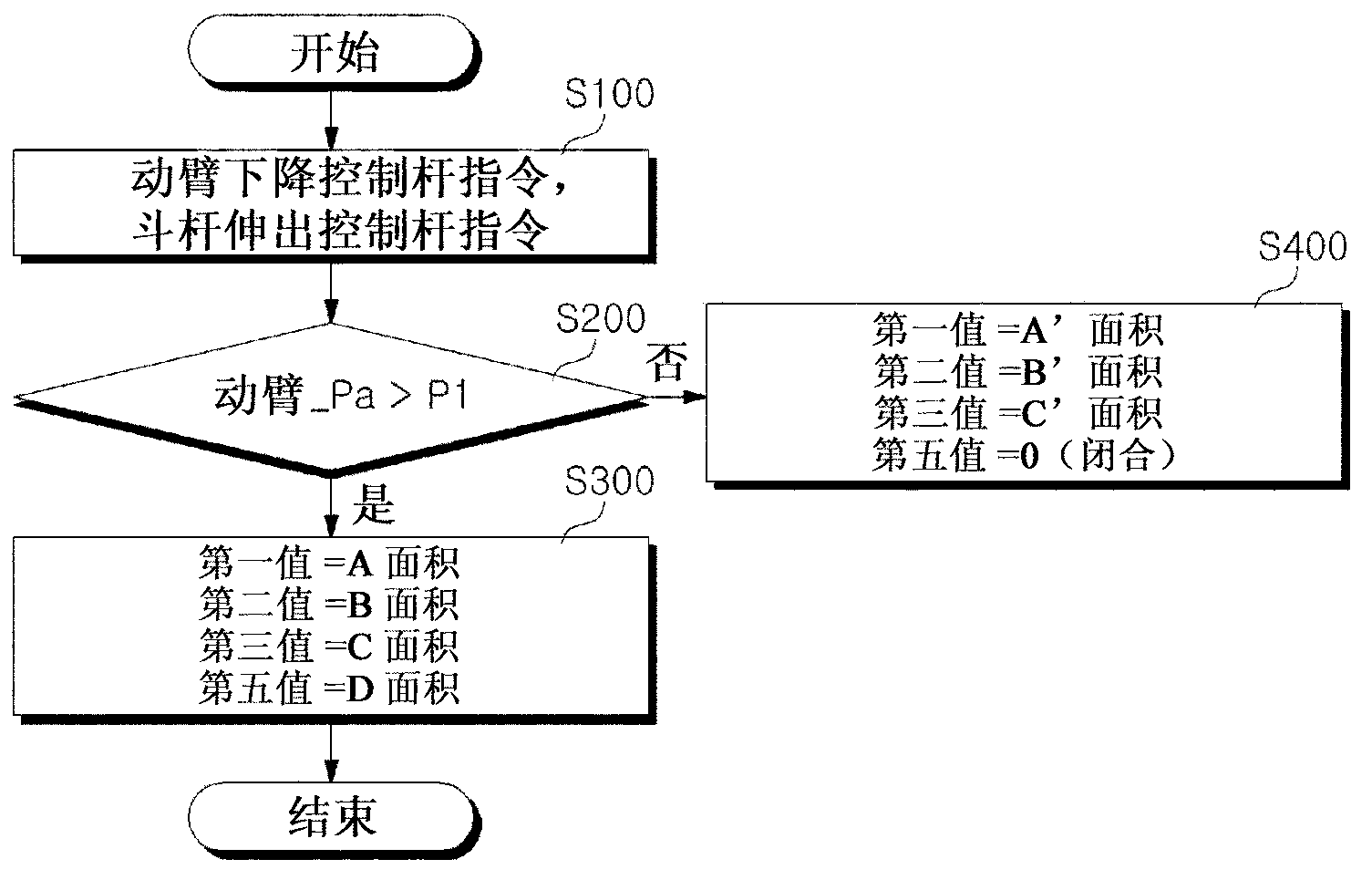

[0058] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings. Objects defined in the detailed description, such as detailed configurations and elements, are merely specific details provided to assist those skilled in the art in a comprehensive understanding of the present invention, and the present invention is not limited to the embodiments disclosed below.

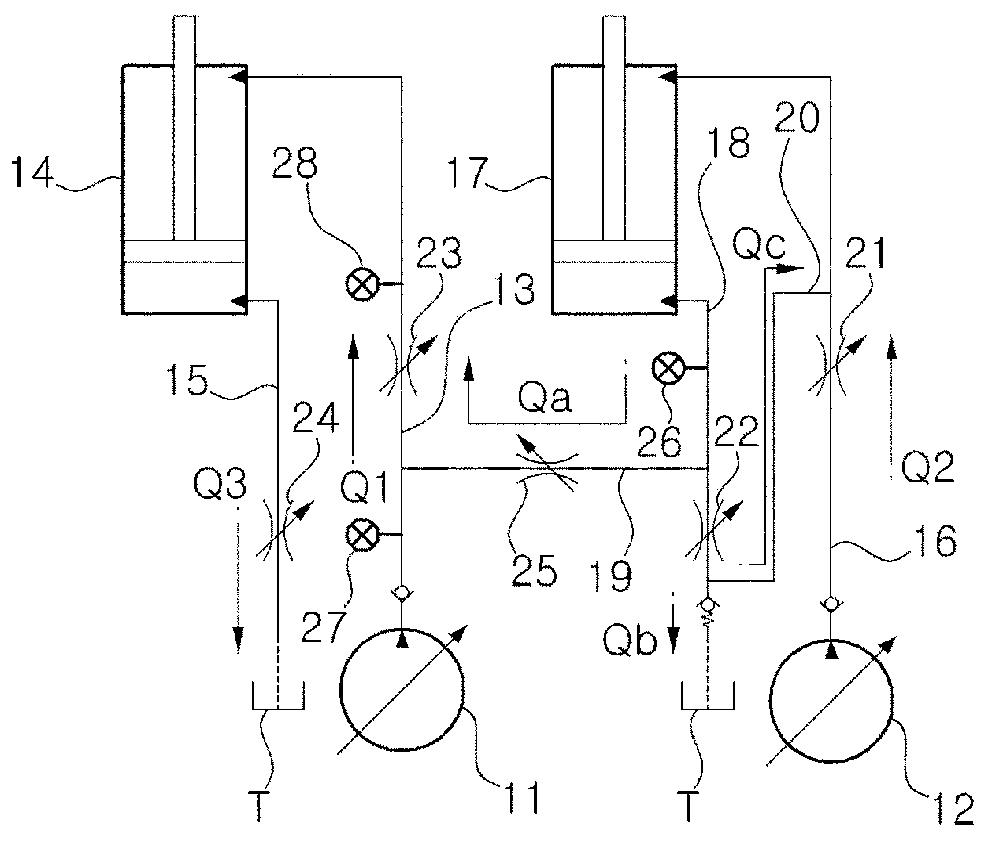

[0059] Such as figure 2 As shown, the energy regeneration system for construction machinery according to an embodiment of the present invention includes:

[0060] first and second variable displacement hydraulic pumps (hereinafter referred to as "first and second hydraulic pumps") 11 and 12, the first and second hydraulic pumps 11 and 12 are connected to an engine (not shown);

[0061] Arm cylinder 14, which has a low-pressure chamber (referred to as a small chamber), which is connected to the first hydraulic pump 11 through the arm extension supply flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com