Application of biogas slurry in shiitake

A technology of shiitake mushroom sticks and biogas slurry, which is applied in the fields of application, horticulture, and botany equipment and methods, and can solve problems such as waste of resources and secondary pollution of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

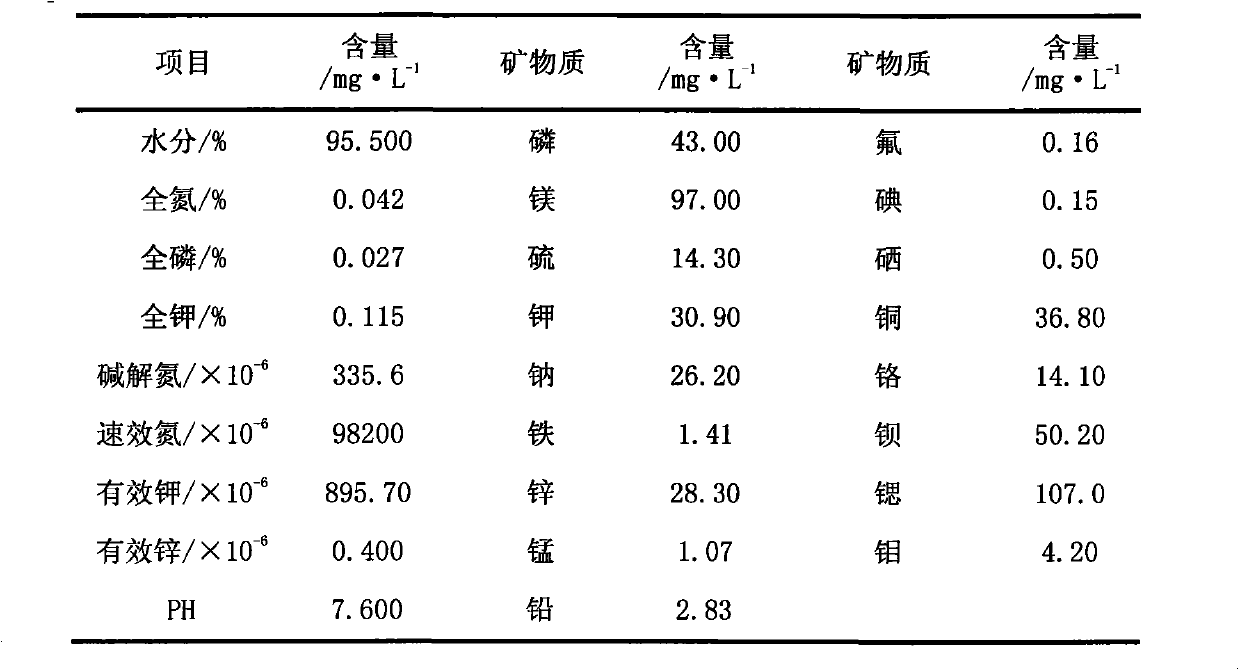

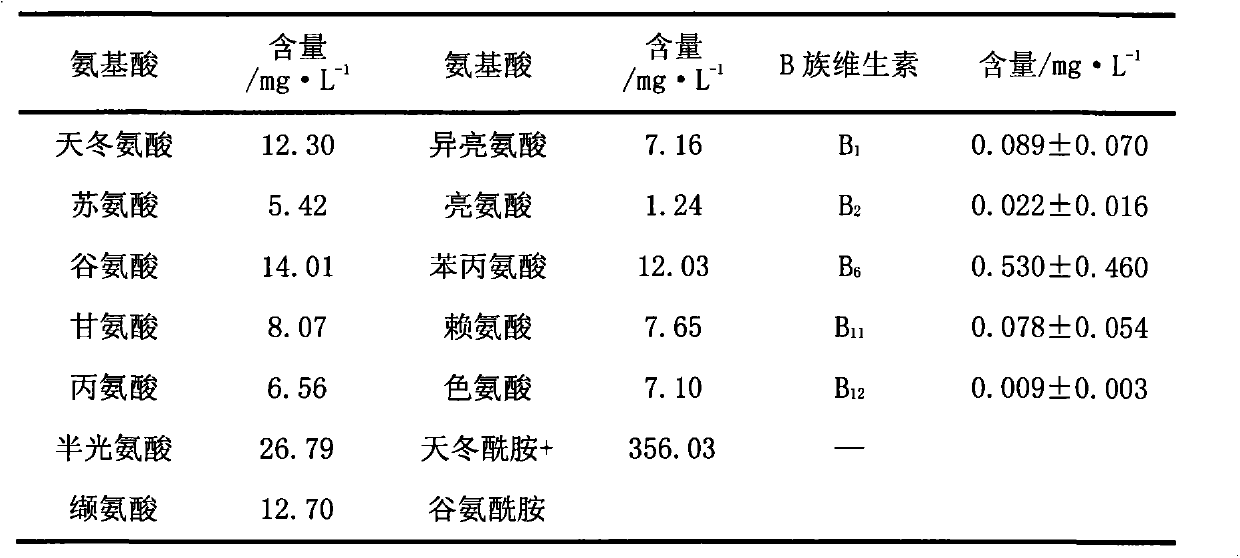

[0020] Mushroom substitute mushroom sticks, compost formula: miscellaneous wood chips 40%, cottonseed hulls 38%, bran 20%, gypsum powder 1%, sugar 1%; use a high-pressure polyethylene bag with a folding width of 15cm, a length of 60cm, and a thickness of 0.05mm Cylinder and stick standard are the length of the column (45±1) cm and the weight of the bag (2.3±0.1) kg; the sticks were made on September 7, the bag was removed on October 15, and the fruiting began in early November.

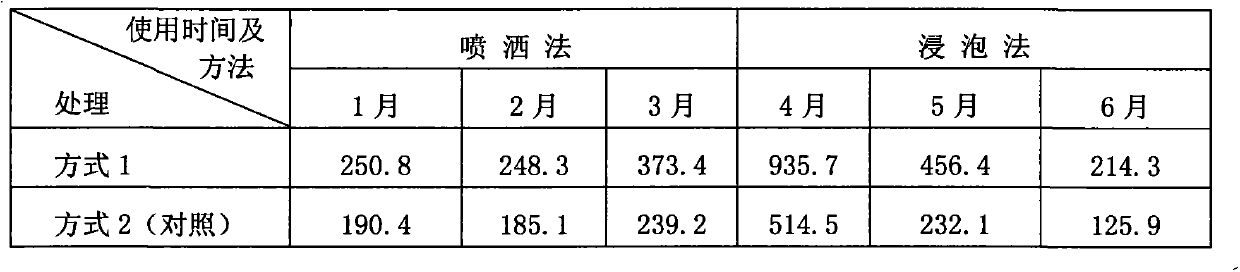

[0021] Method 1: In this embodiment, the mushroom sticks made of the above-mentioned cultivation materials are used for fruiting management. Spray with biogas slurry diluted 1 times in January, February, and March, spray once every 1 day, and spray each wet mushroom 3 times, and count the output on a monthly basis; use direct soaking in April, May, and June method to supplement water and nutrients, first use No. 8 iron wire to punch a few 15cm deep holes at both ends of the fungus sticks, move the fun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com