A rapid film coating device and method in a laboratory

A coating device and laboratory technology, applied in the field of rapid coating devices in the laboratory, can solve the problems of inability to adapt to rapid coating, occupy a large space, and use a large amount of coating agent, so as to improve efficiency, reduce occupied space, The effect of short coating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

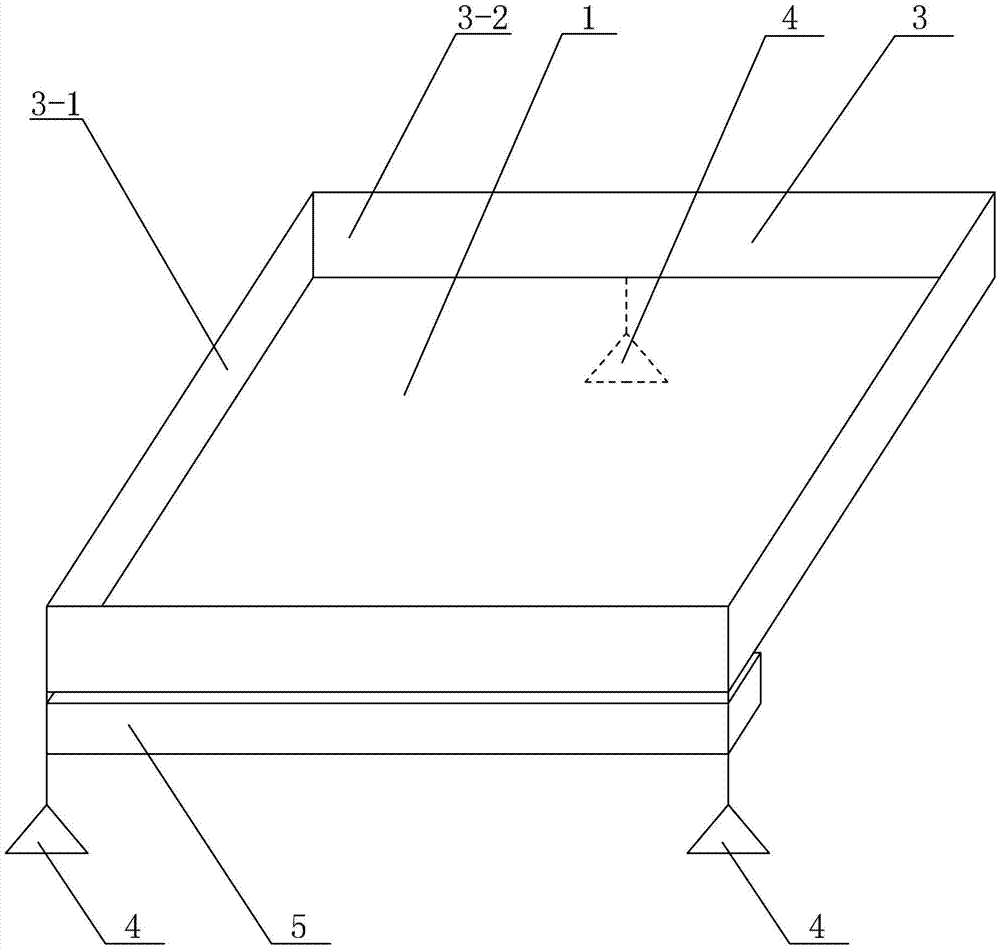

[0013] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, a kind of rapid film coating device in the laboratory described in this embodiment includes a support plate 1, a coating rod 2, a pasting frame 3, a liquid receiving tank 5 and three balance supports 4, and the support plate 1 is horizontally arranged. Paste frame 3 is installed on the upper surface of support plate 1, three balance brackets 4 are arranged on the lower surface of support plate 1 in an equilateral triangle, liquid receiving tank 5 is arranged below support plate 1, and coating rod 2 is used for The paint is dipped from the support plate 1 for coating.

specific Embodiment approach 2

[0014] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the pasting frame 3 of a rapid film coating device in a laboratory described in this embodiment is a rectangular frame composed of two long pasting boards 3-1 and two short pasting boards 3-2.

[0015] The technical effect of this embodiment is: the rectangular frame composed of two long pasting boards 3-1 and two short pasting boards 3-2 can be set and adjusted according to the thickness of the required coating film. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0016] Specific implementation mode three: combination figure 1 with figure 2 Illustrate this embodiment, the support plate 1 of a kind of rapid film coating device in the laboratory described in this embodiment is a glass plate or a stainless steel plate, the length of the support plate 1 is 310mm, the width of the support plate 1 is 220mm, and the length of the support plate 1 The thickness is 15mm-20mm.

[0017] The technical effect of this embodiment is: the support plate 1 is made of glass plate or stainless steel plate, so that the support plate 1 is not easily corroded, prolongs the service life of the support plate 1, and avoids the coating film pollution caused by the support plate 1 corrosion. Other components and connections are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com