Amphibious vehicle suspension folding and unfolding mechanism

A vehicle suspension and folding mechanism technology, which is applied in the field of vehicle engineering, can solve the problems of slow response speed, large space occupation, and complex structure of wheel folding, and achieve the effect of quick action, small space occupation, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

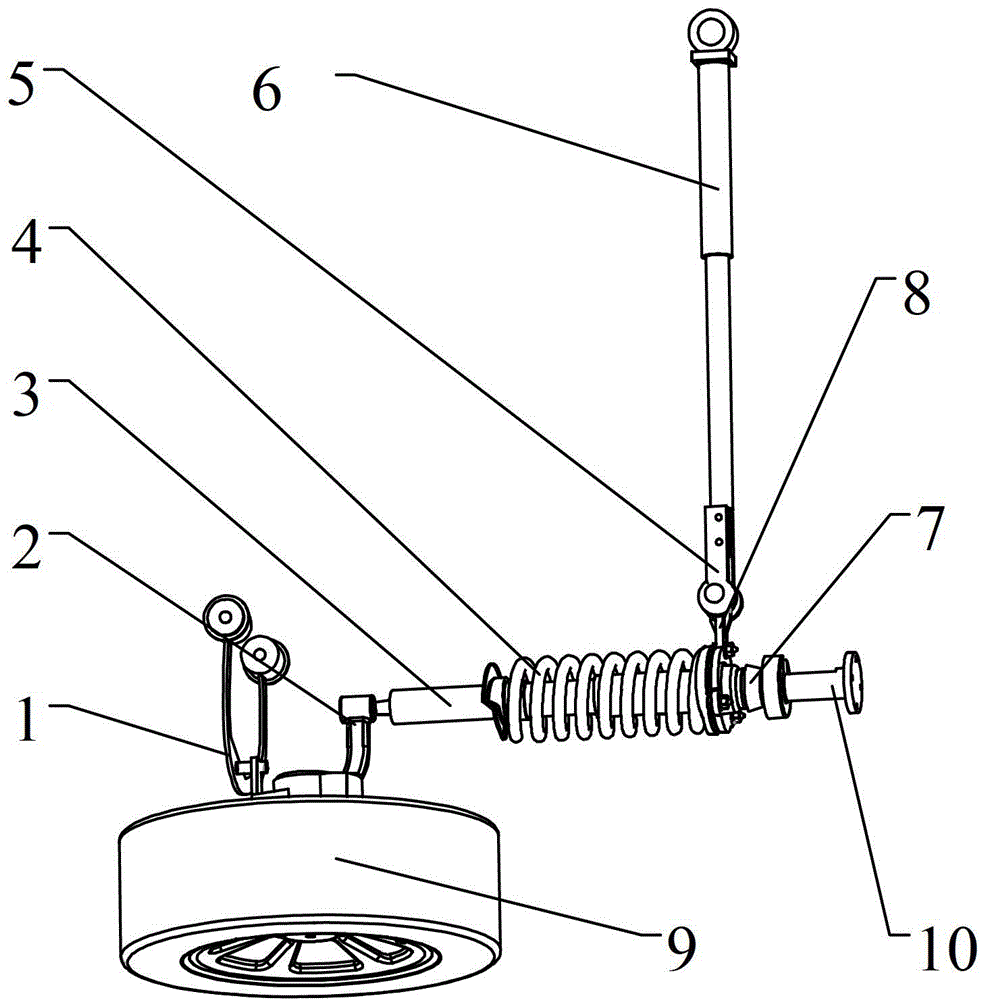

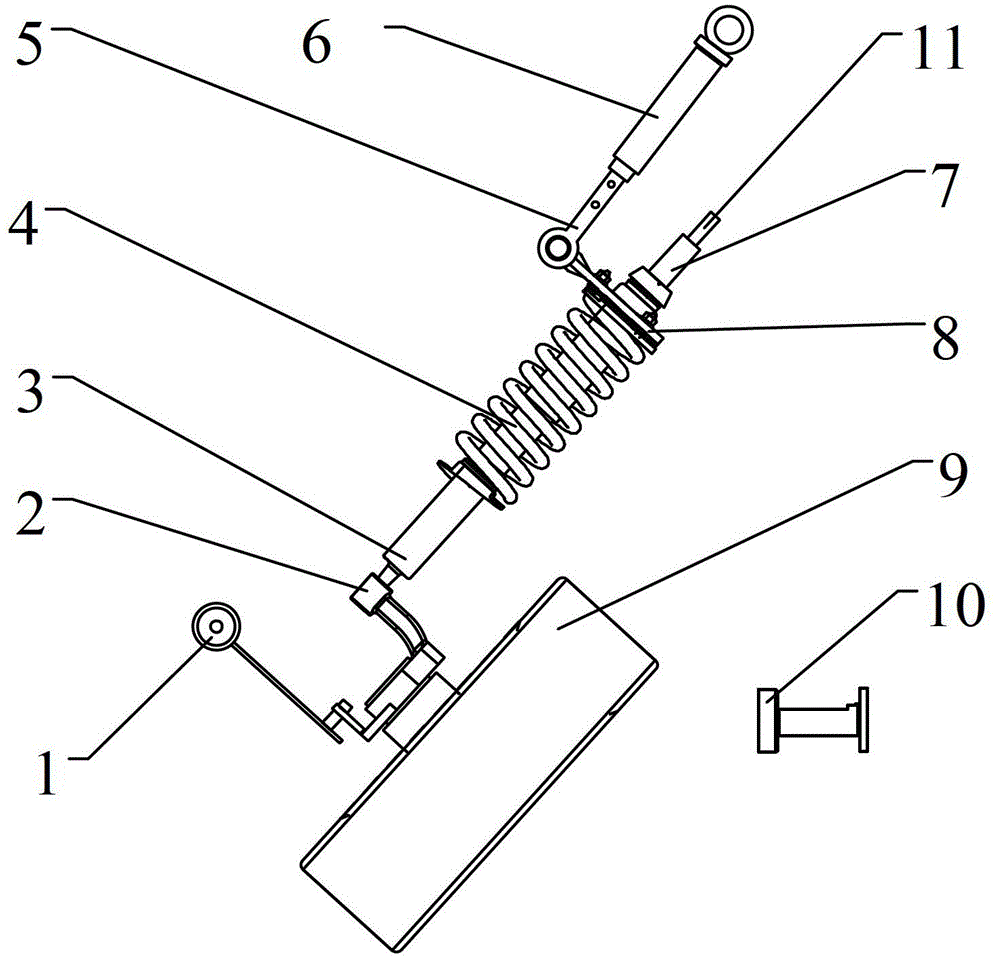

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

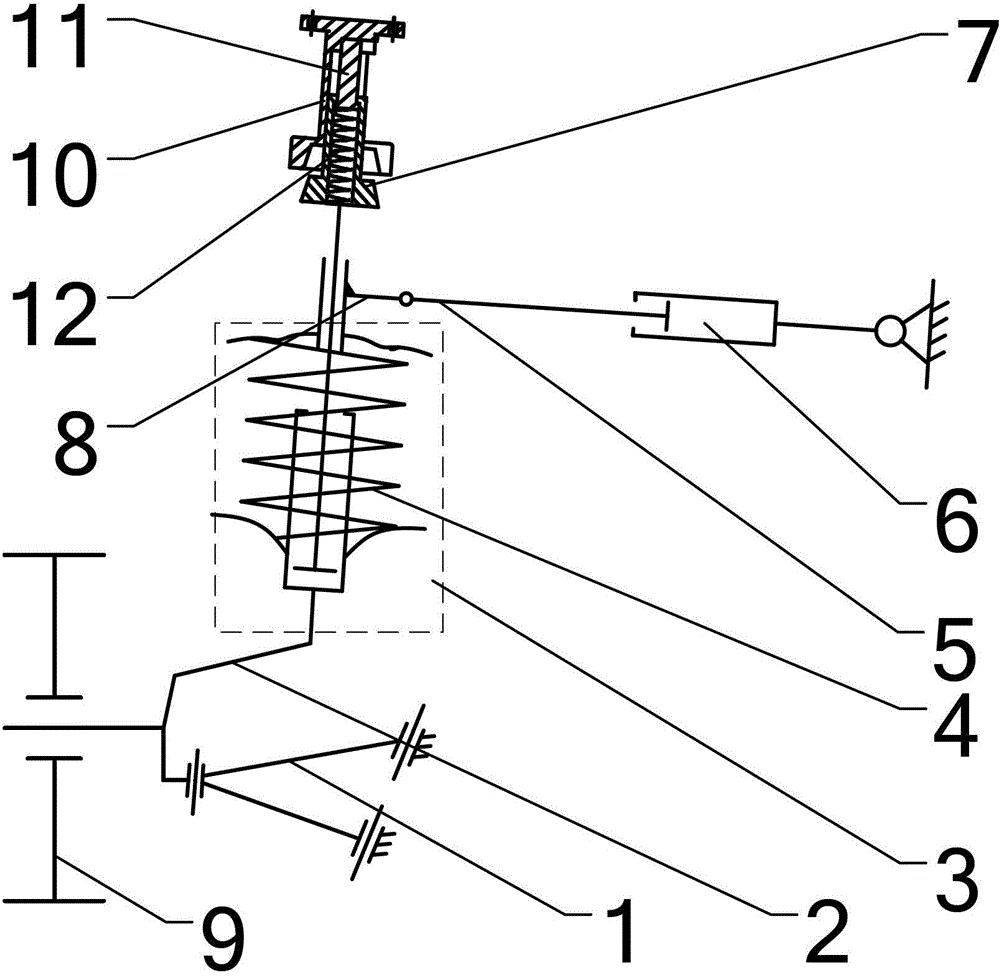

[0018] Such as figure 1 , figure 2 and image 3 As shown, the suspension folding mechanism of an amphibious vehicle includes an A-shaped lower support arm 1, a steering knuckle 2, a shock absorber 3, a connecting rod 5, a driving cylinder 6, a locking cone head 7, a connecting plate 8, a wheel 9, and a locking cone Cover 10, locking push rod 11 and taper spring 12.

[0019] The two ends of the bottom of the A-shaped lower support arm 1 are respectively hinged on the vehicle frame, and the top is hinged with the bottom of the steering knuckle 2. The A-shaped lower support arm is set horizontally as a whole; , the top is affixed to the shock absorber cylinder of the shock absorber 3;

[0020] The shock absorber 3 includes a shock absorber cylinder, a shock absorber piston rod and a coil spring 4, and the shock absorber is vertically arranged as a whole; one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com