Guide frame type middle-turning dumper carriage

A diversion edge and frame-type technology, which is applied to vehicles with loading ramps and vehicles with inclined load movement, etc., can solve the problems of easy damage to the sub-frame, time-consuming and labor-intensive unloading, and weak support of the bottom plate and sub-frame. , to achieve the effects of not being easily damaged, improving the service life and smooth unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

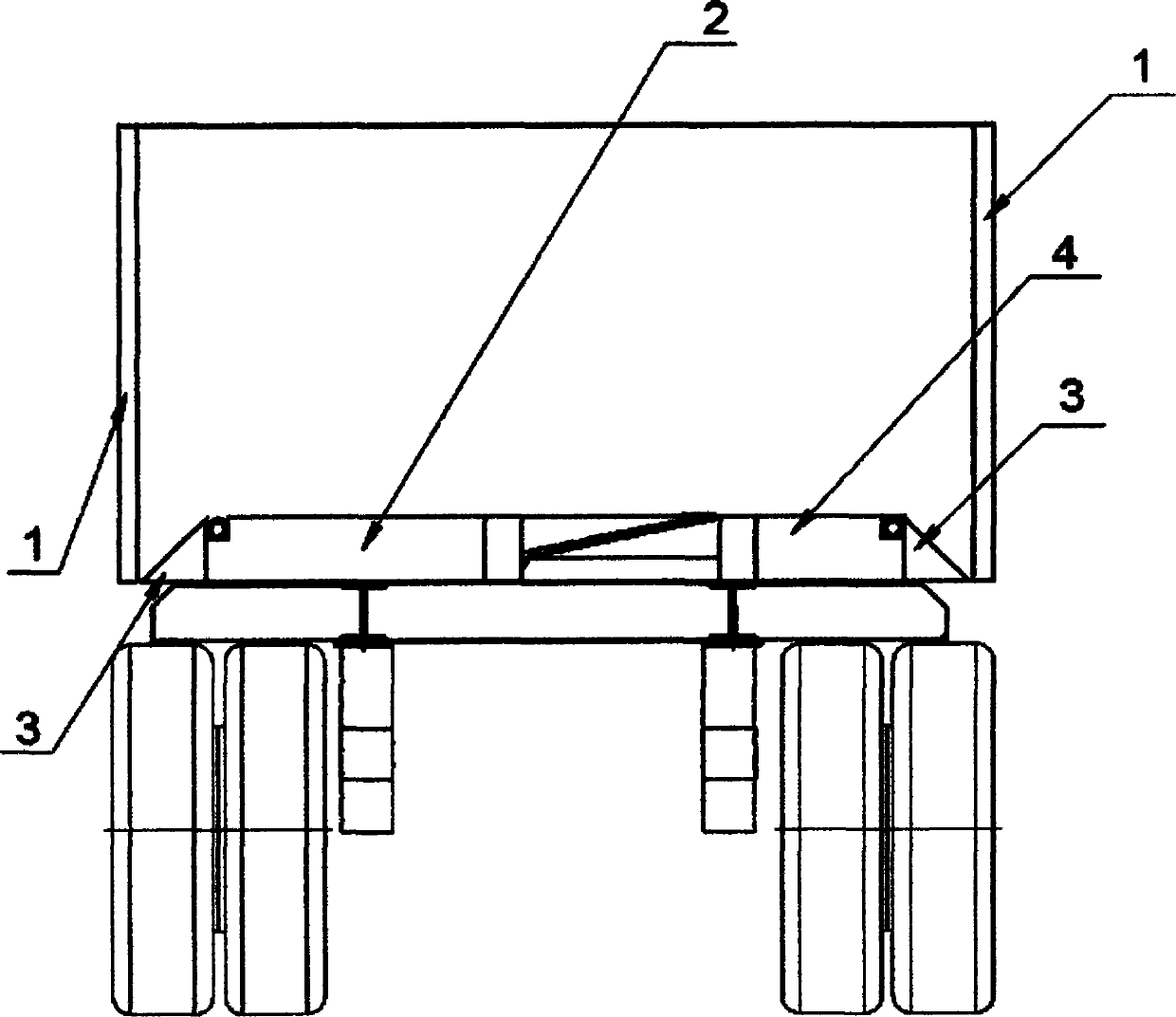

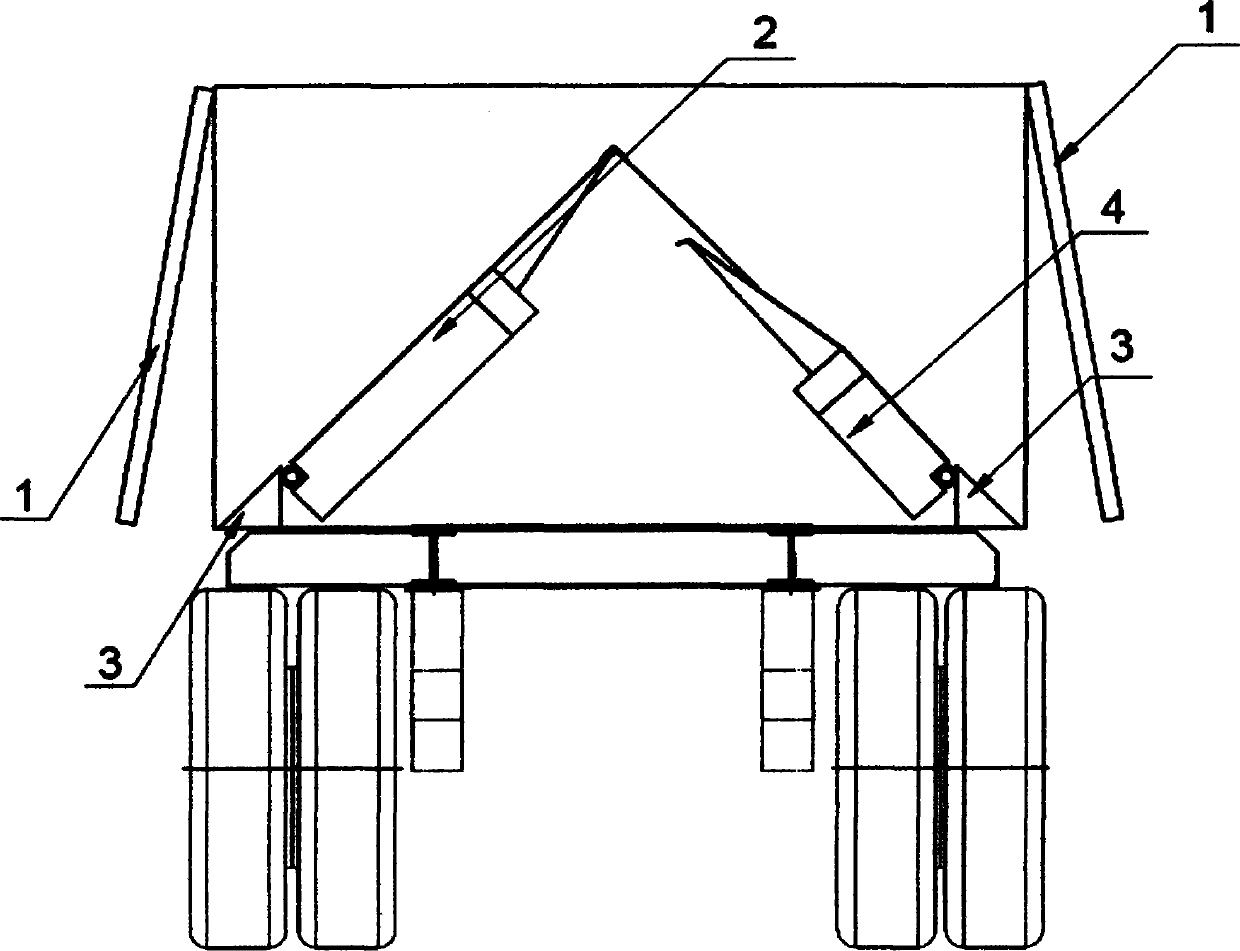

[0023] According to an embodiment of the present invention, a guide frame type dump truck is provided. Such as figure 1 with figure 2 As shown, the diversion frame type dump truck of the present embodiment includes a bottom plate, symmetrical side plates (such as side plates 1) vertically installed on both sides of the bottom plate, and cooperatingly installed between the bottom plate and the side plates. Fixed air guide frame (such as fixed air guide frame 3). Here, the side plates are vertically arranged on both sides of the bottom plate, which can be opened and closed for loading and unloading.

[0024] In the above-described embodiment, the base plate includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com