Packaging production line for toy blocks

A technology for packaging production lines and building blocks, which is applied to the field of packaging production lines for toy building blocks, can solve the problems of incorrect number of building block components, high labor intensity of workers, low production efficiency, etc., and achieves the effects of high production efficiency, saving manpower and material resources, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

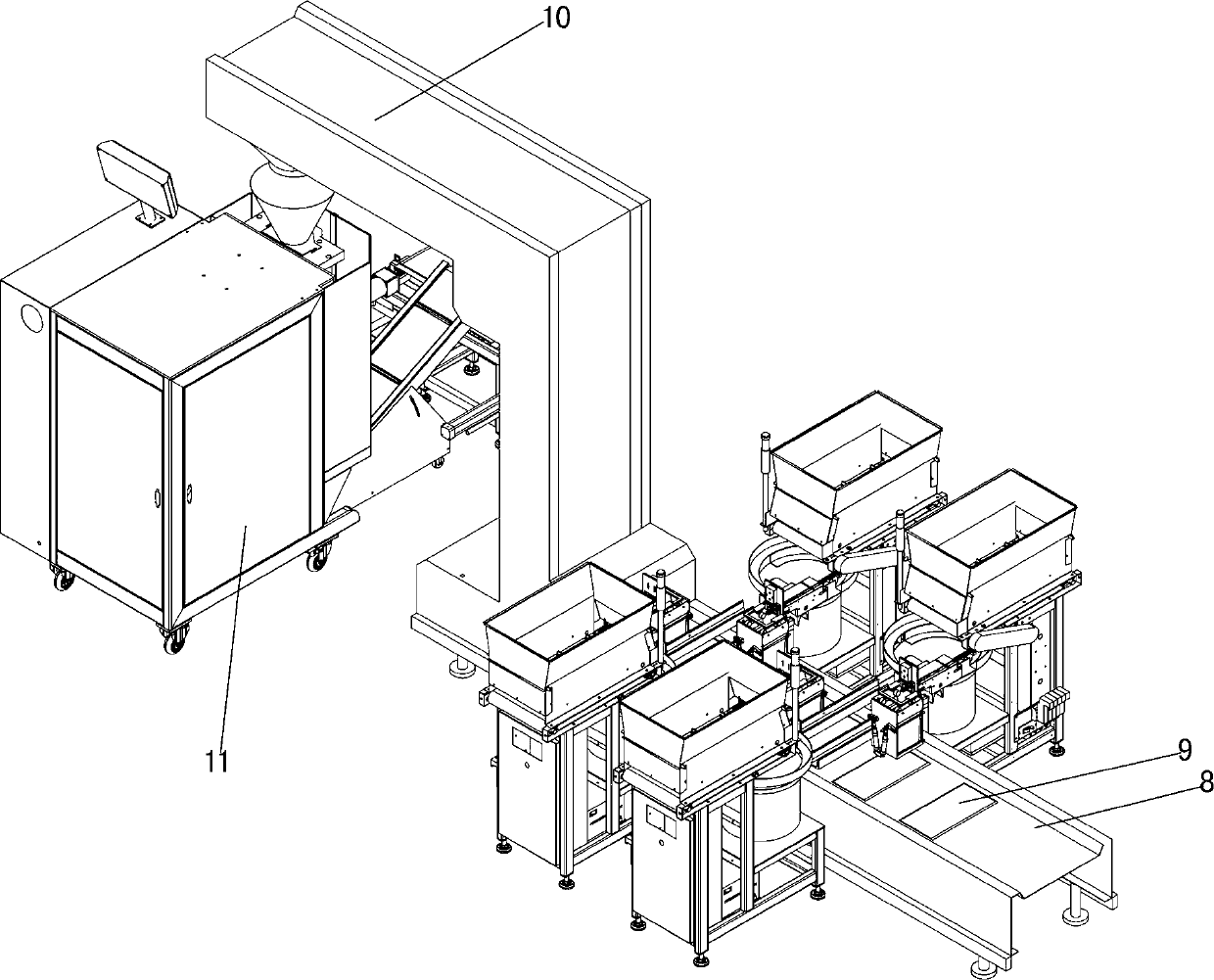

[0022] Such as figure 1 As shown, the packaging production line of toy building blocks in this preferred embodiment includes a filling mechanism 10, a bag making machine 11, a conveyor belt 8 and 4 blanking mechanisms that are provided with a storage tank 9 for collecting various building block assemblies, and Each blanking mechanism is distributed along the conveyor belt 8 in sequence. In this embodiment, in order to reduce the occupied area and make full use of the space, the four blanking mechanisms are located on the left and right sides of the conveyor belt 8 respectively, and are arranged alternately in sequence. The filling mechanism 10 is located at the conveyor belt outlet 8, and the bag making machine 11 is located below the filling port of the filling mechanism.

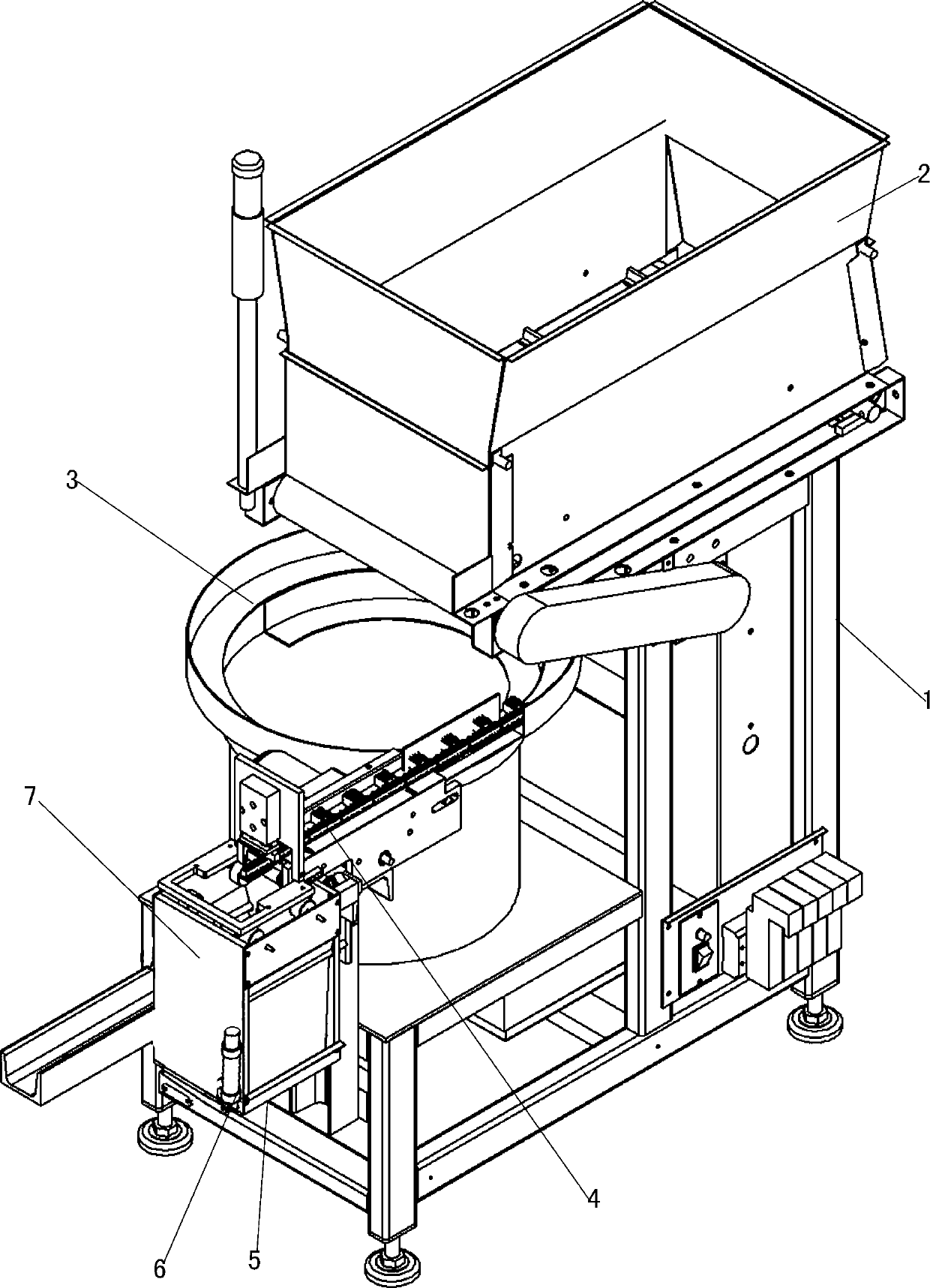

[0023] Such as figure 2 As shown, the blanking mechanism includes a frame 1, a hopper 2, a vibration plate 3, and a quantitative storage hopper 7.

[0024] The hopper 2, the vibrating plate 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com