Cement concrete strength improver

A technology of cement concrete and enhancer, applied in the field of cement concrete strength enhancer, can solve problems such as difficulty in enhancing strength and increase production cost, and achieve the effects of reducing production cost and improving cement strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

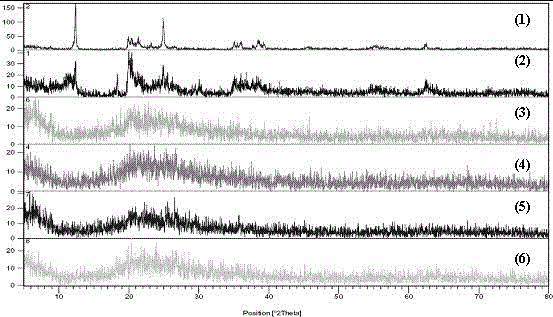

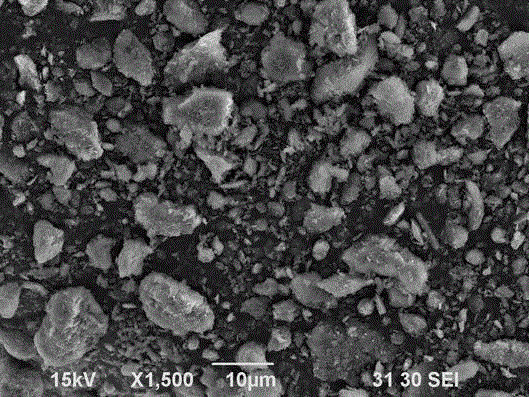

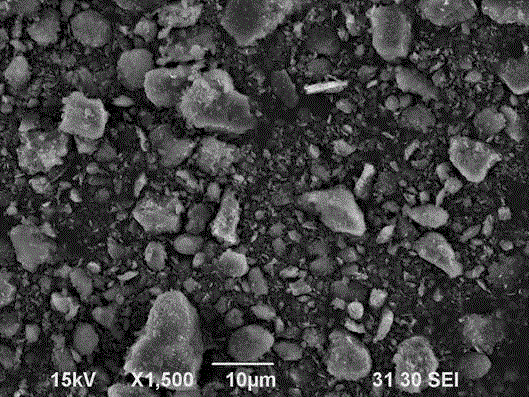

Image

Examples

Embodiment 1

[0027] A cement concrete strength enhancer, in parts by weight, its preparation raw materials include 90 parts of granular metakaolin with a particle size of 10-3 μm, 10 parts of needle-shaped and long columnar metakaolin with a particle size of 10-3 μm; wherein, the granular metakaolin The aspect ratio of acicular and long columnar metakaolin is 2.9; the aspect ratio of metakaolin is 3.1;

[0028] The preparation method of metakaolin is:

[0029] (1) In parts by weight, weigh 80 parts of granular kaolinite with a particle size of 20 to 3 μm, and 20 parts of acicular and elongated columnar halloysite with a particle size of 10 to 3 μm; the aspect ratio of the granular kaolinite is 2.9; The aspect ratio of acicular and long columnar halloysite is greater than 4.6;

[0030] (2) Add the granular kaolinite and acicular and columnar halloysite weighed in step 1 into the mixer according to the proportion and mix until uniform;

[0031] (3) The mixture obtained in step 2 is roasted...

Embodiment 2

[0034] The same part of this example and Example 1 will not be repeated, the difference is: in parts by weight, weigh 90 parts of granular kaolinite with a particle size of 20-3 μm, and acicular and long columnar stones with a particle size of 10-3 μm Halloysite 10 parts.

Embodiment 3

[0036] The same parts of this example and Example 1 will not be repeated, the difference is: in parts by weight, weigh 50 parts of granular kaolinite with a particle size of 20-3 μm, and acicular and long columnar stones with a particle size of 10-3 μm Halloysite 50 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap