Improved Z-pin method for two-dimensional ceramic matrix composite

A technology of composite materials and composite material boards, applied in the field of Z-pin, can solve the problems of not being able to fully exert mechanical properties, achieve the effect of not losing shear strength, improving Z-direction strength, and reducing fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

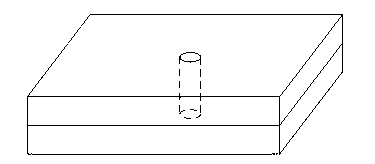

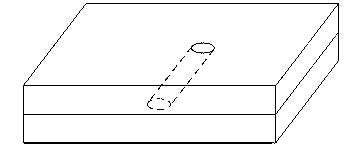

Image

Examples

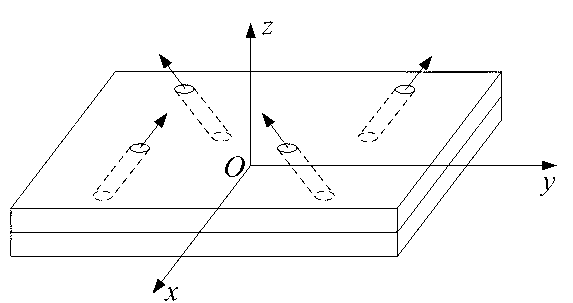

Embodiment 1

[0036] (1) Prepare a two-dimensional carbon fiber plain weave preform, the size of which is 50×50×5mm 3 ;

[0037](2) The carbon fiber Z-pin component is prepared by pultrusion molding process, and the carbon fiber Z-pin component with the design length and diameter (0.2-1.0mm) is obtained after the heating mold is solidified and cut. Carbon fiber Z-pin components, using 3k carbon fibers to prepare carbon fiber Z-pin components with a diameter of 0.50mm;

[0038] (3) The oblique holes are drilled on the two-dimensional carbon fiber plain weave prefabricated body. The distribution rules of the oblique holes on the two-dimensional carbon fiber plain weave prefabricated body are as follows: Define the oblique hole axial direction and the two-dimensional carbon fiber plain weave prefabricated body method The angle included in the direction is the oblique angle θ, the center of the lower surface of the two-dimensional carbon fiber plain weave prefabricated body is the origin O of ...

Embodiment 2

[0059] Described θ=15 °, all the other are the same as embodiment 1

Embodiment 3

[0061] Described θ=30 °, all the other are the same as embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com