Eccentric type self-locking nut

A self-locking nut, eccentric technology, applied in the direction of nuts, screws, bolts, etc., to achieve the effect of simple processing technology, reasonable force, convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

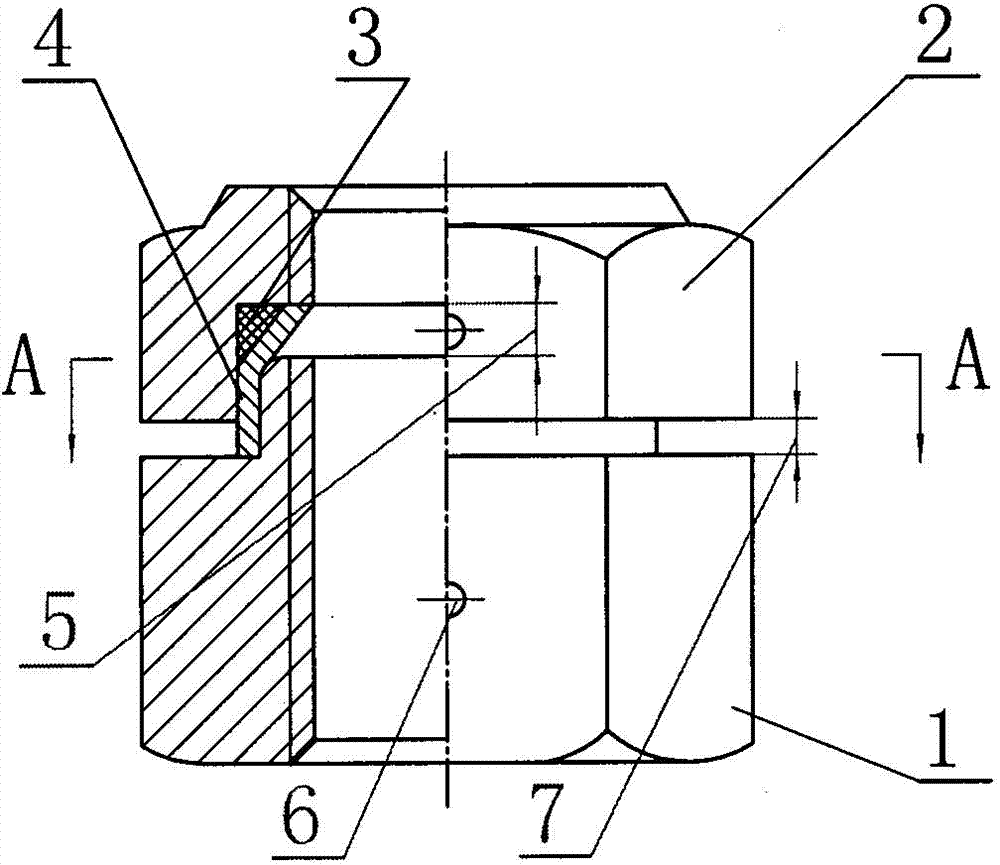

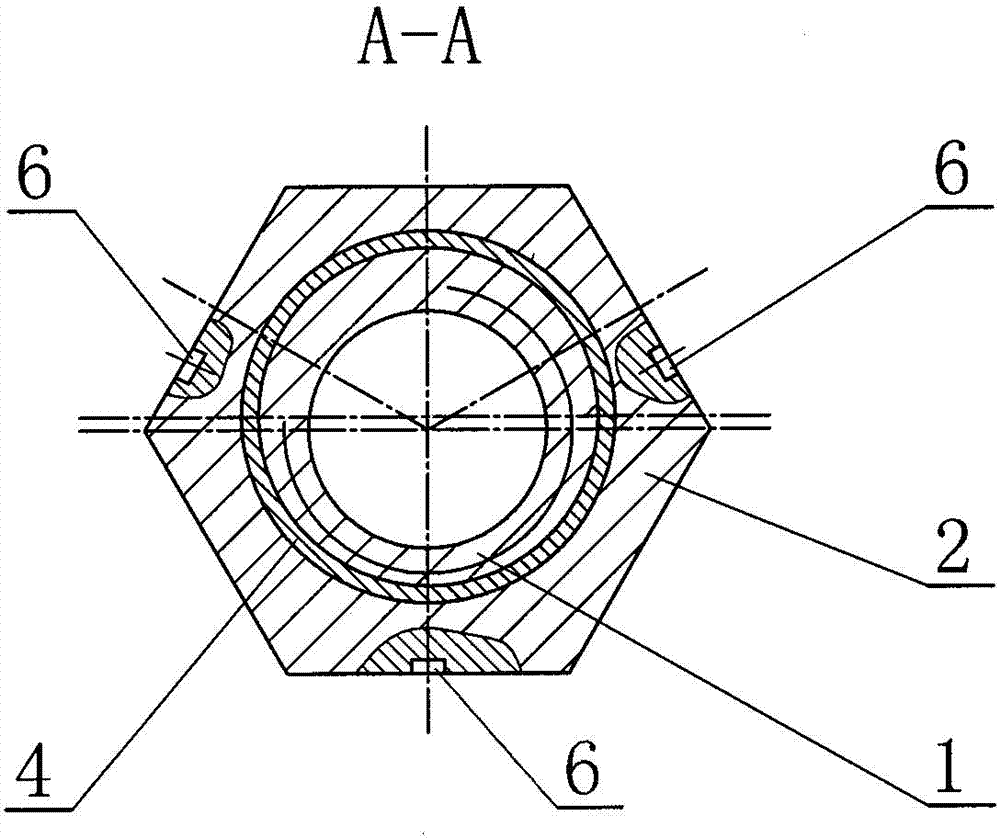

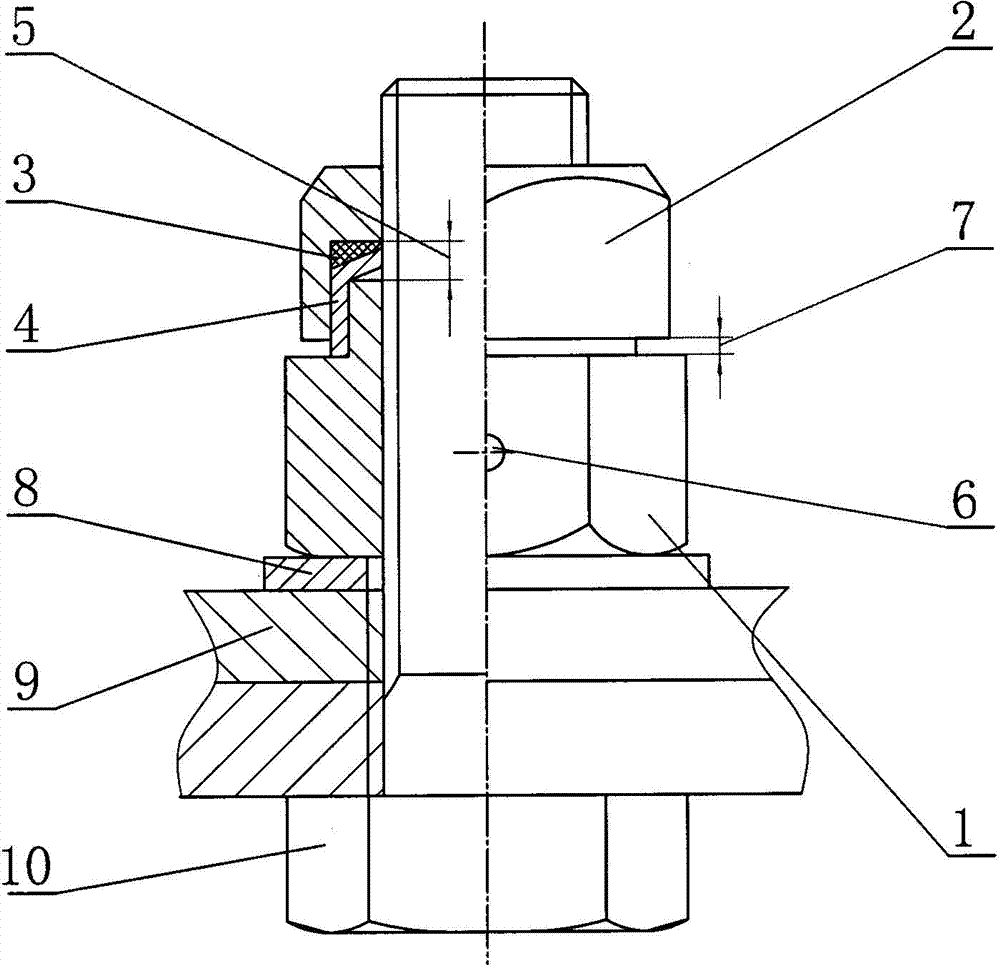

[0015] according to Figure 1 ~ Figure 4 The specific structure of the present invention will be described in detail. The eccentric self-locking nut includes a lower body 1 with an eccentric boss on the upper part, and an upper body 2 with an eccentric hole on the lower part. The upper and lower bodies 2 and 1 have the same internal thread as the connecting bolt 10, and they are on the same axial centerline. superior. Wherein, the eccentric boss of the lower body 1 and the eccentric hole of the upper body 2 are closely fitted and fixed through a thin-walled sleeve 4 with a tapered frustum. In order to meet the needs of different elastic deformation and the formed friction coefficient, the thin-walled sleeve 4 with frustum of cone can be made of metal material or non-metallic material as an integral structure, a split structure or a combined structure composed of at least two sleeves . There are two main functions of the above-mentioned connection and fixation: one is to gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com