Rotary heat engine

A heat engine and rotary technology, applied in the field of internal combustion engines and rotary engines, can solve problems such as inability to exceed performance, and achieve the effect of simple cooling, simple manufacturing or mass production, and high power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Looking at the previous figures, you can see various preferred examples of implementing the present invention according to the numbers used. The present invention includes the various components and elements shown and described.

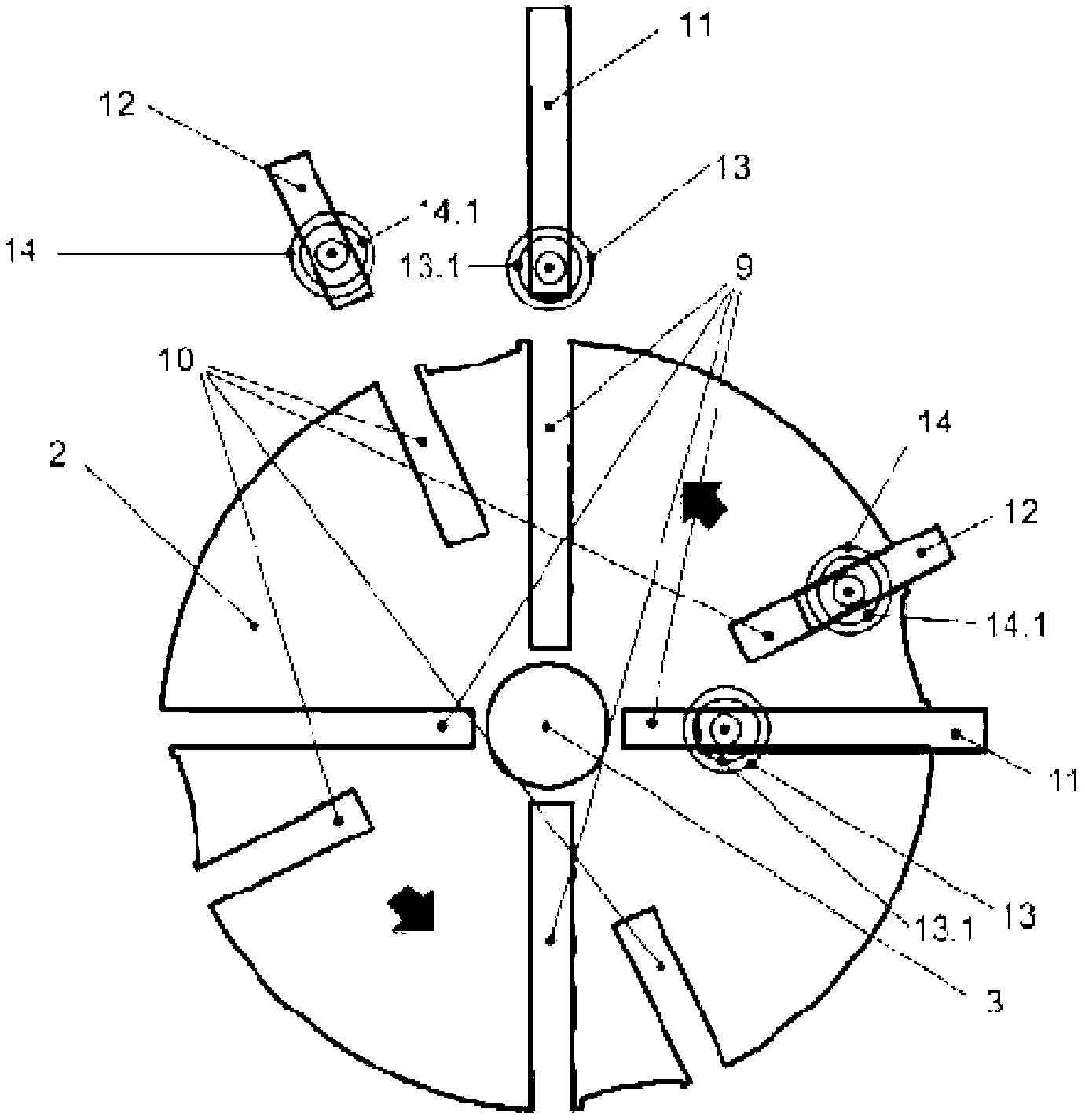

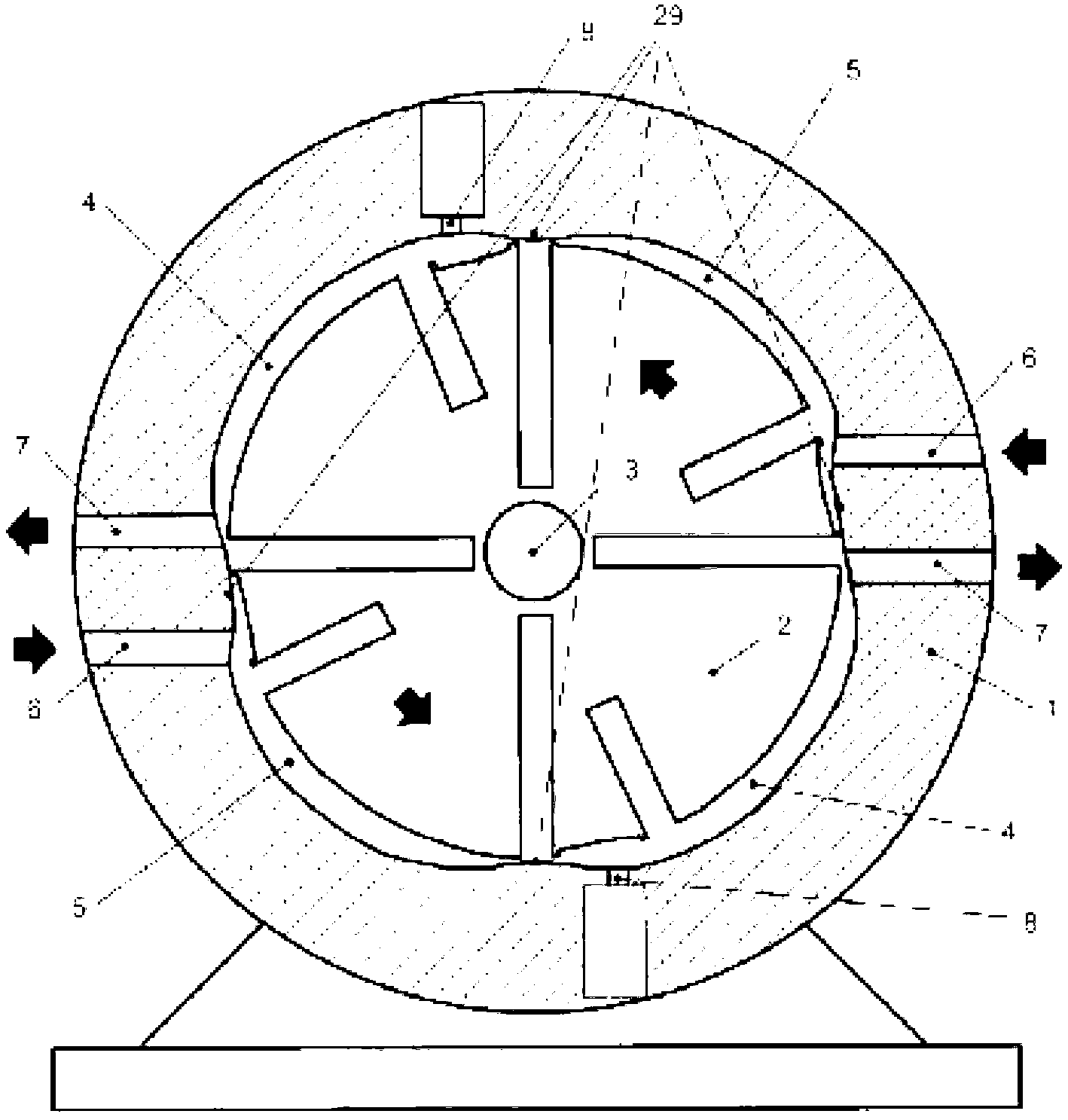

[0058] in figure 1 , The rotor 2 associated with the shaft 3 can be observed. The rotor has a cylindrical structure. There are opposing grooves on its periphery and some diametrically opposing slots 9 and 10, which define four regions.

[0059] These slots are drawn in a radial manner (pointing to the center of the rotor). However, the slots can also take other suitable forms, for example, positioned parallel to each other.

[0060] Each of the four regions defined in the rotor 2 has a slot 9 with a high depth and another slot 10 with a low depth. The pair of slots are respectively used to guide some blades 11 for feeding / compression and some blades 12 for expansion / discharge.

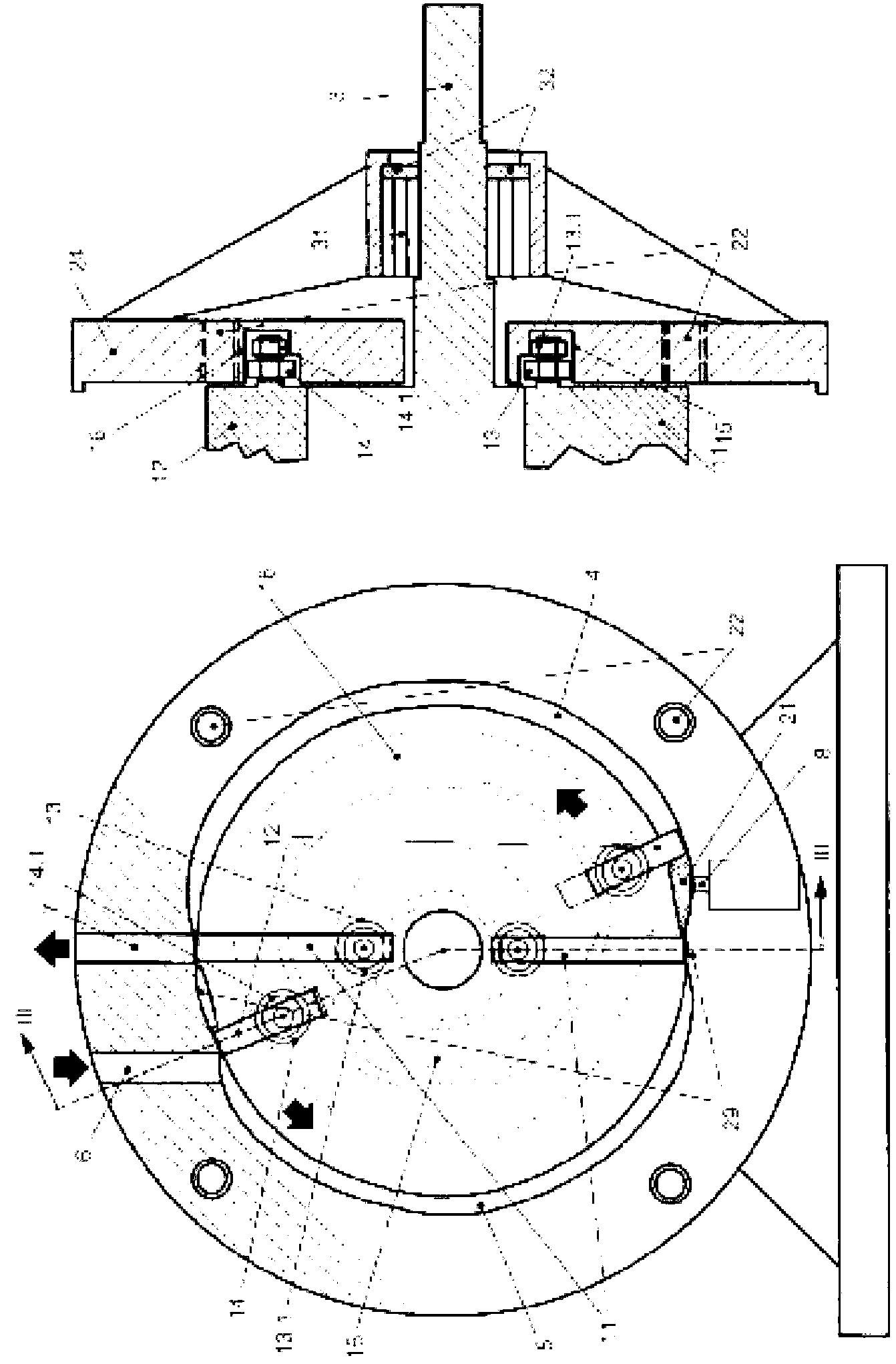

[0061] in image 3 with Figure 4 , The feeding / compression blades 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com