Tire fast pretightening device for passenger car

A passenger car, pre-tightening technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of poor man-machine operability, low efficiency, slow manual tightening speed, etc., and achieve the effect of simple structure and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical problems solved by the present invention, the technical solutions adopted, and the technical effects obtained easy to understand, the specific implementation manners of the present invention will be further described below in conjunction with the specific drawings.

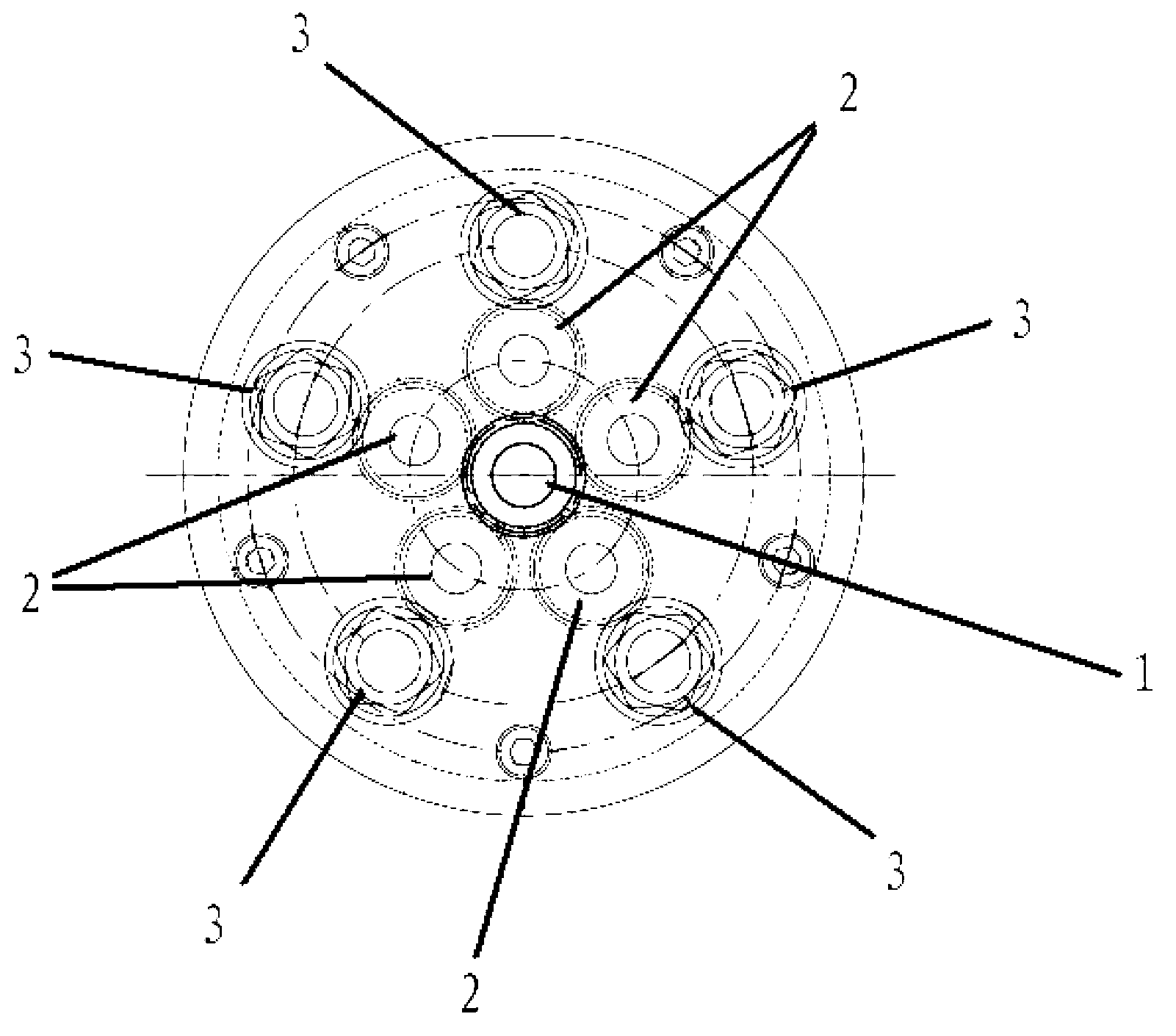

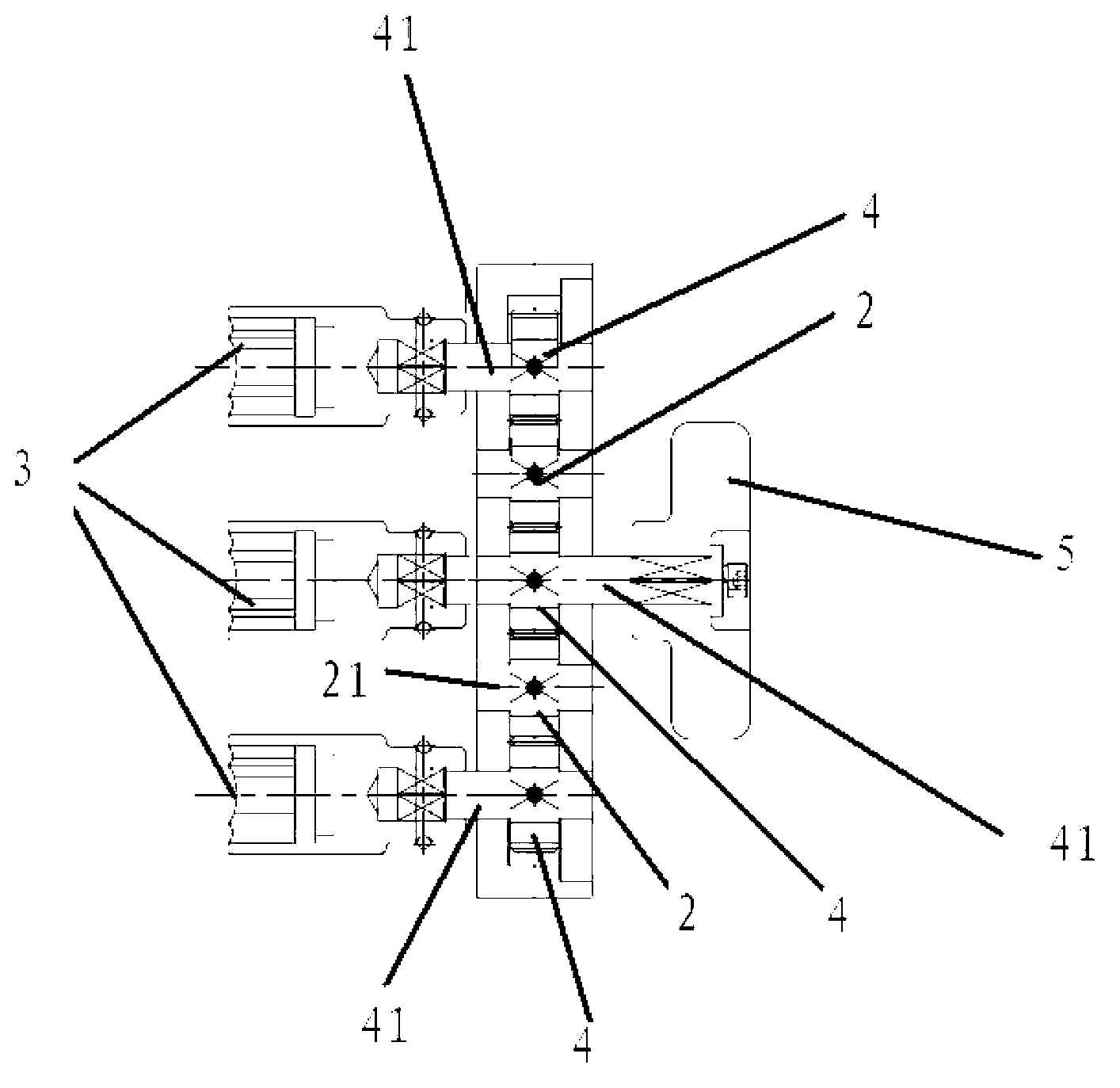

[0013] refer to figure 1 , figure 2 , the invention discloses a quick pre-tightening device for passenger car tires, which comprises a cylindrical shell shell, a drive shaft is rotatably connected to the shell, a drive gear 1 is fixed on the drive shaft, and a plurality of connecting There are driven shafts 41 of the nut sleeve 3. In a specific embodiment of the present invention, five driven shafts 41 are arranged, which are equidistantly distributed in the circumferential direction of the driving shaft. On each driven shaft 41 Fix a driven gear 4 respectively, in a specific embodiment, driven gear 4 of the present invention meshes with driving gear 1 respectively, like thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com