Automatic card cutting device

A cutting device and card technology, applied in metal processing and other directions, can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

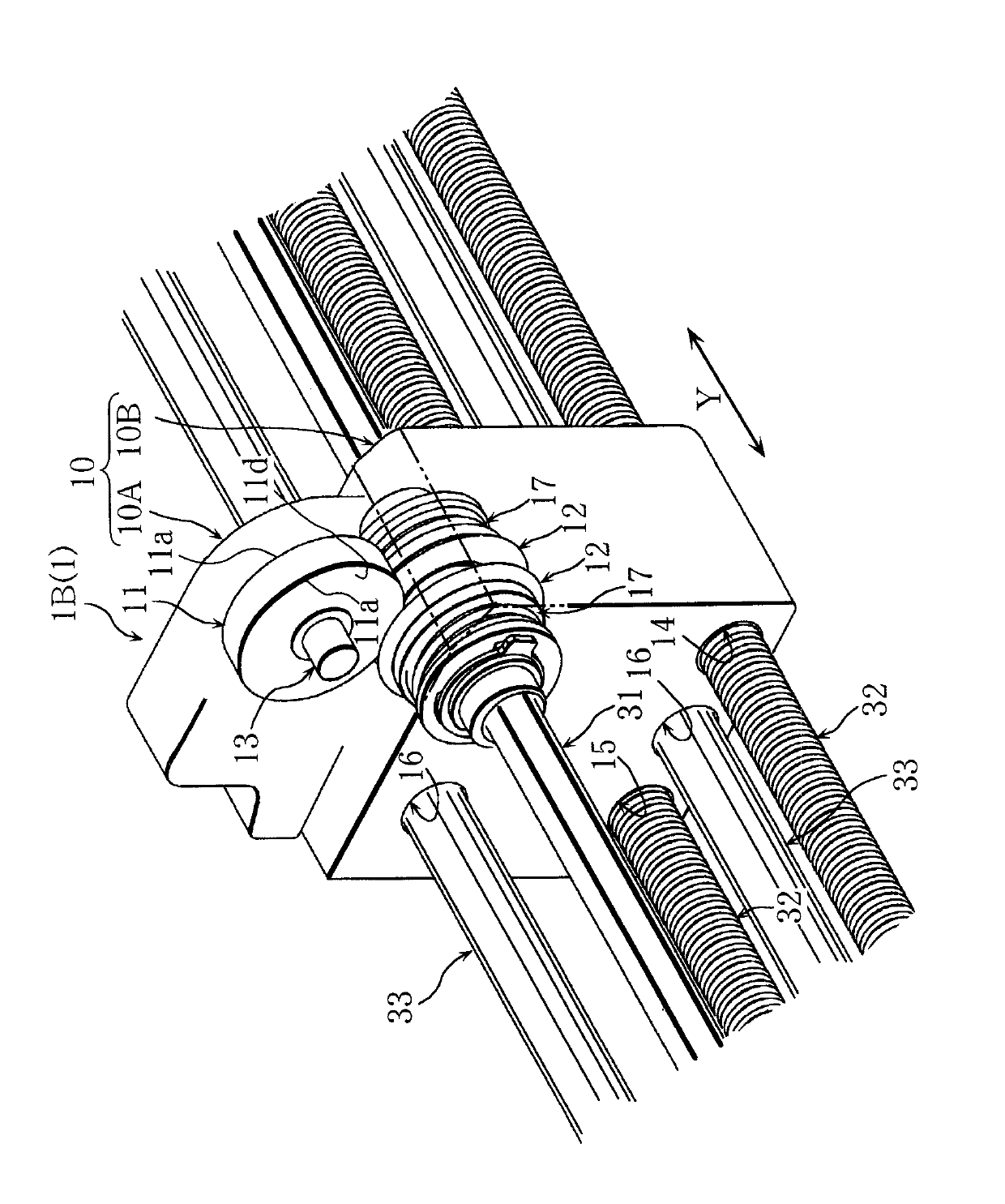

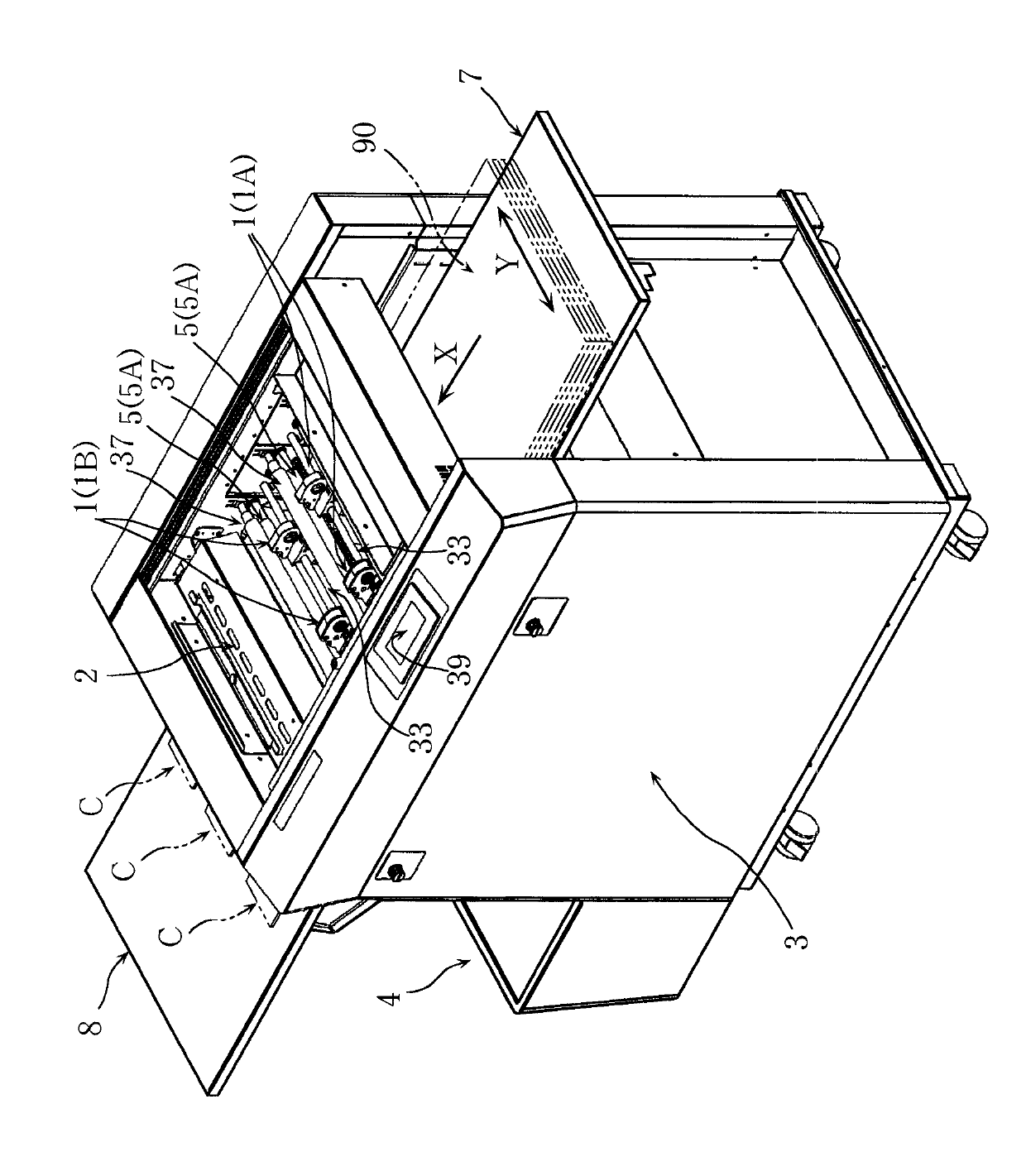

[0020] Preferred embodiments of the present invention will now be described with reference to the accompanying drawings.

[0021] Regarding the automatic card cutting device of the present invention, the main body frame 3 is provided with: a feed table 7, figure 1 The sheets 90 indicated by double-dashed lines are stacked and placed thereon; a plurality of conveying rollers 5 to contact the underside of the sheets 90 and convey the sheets 90 one by one; a plurality of pressing rollers 37 contacting the upper surfaces of the sheets 90, to prevent the paper 90 from floating; a plurality of shear heads 1 to cut the paper 90 in the conveying direction X; and a discharge table 8 on which the cards C formed by cutting the paper 90 and indicated by a two-dot chain line are deposited . Also, a dust box 4 opened upward is provided outside the main body frame 3 .

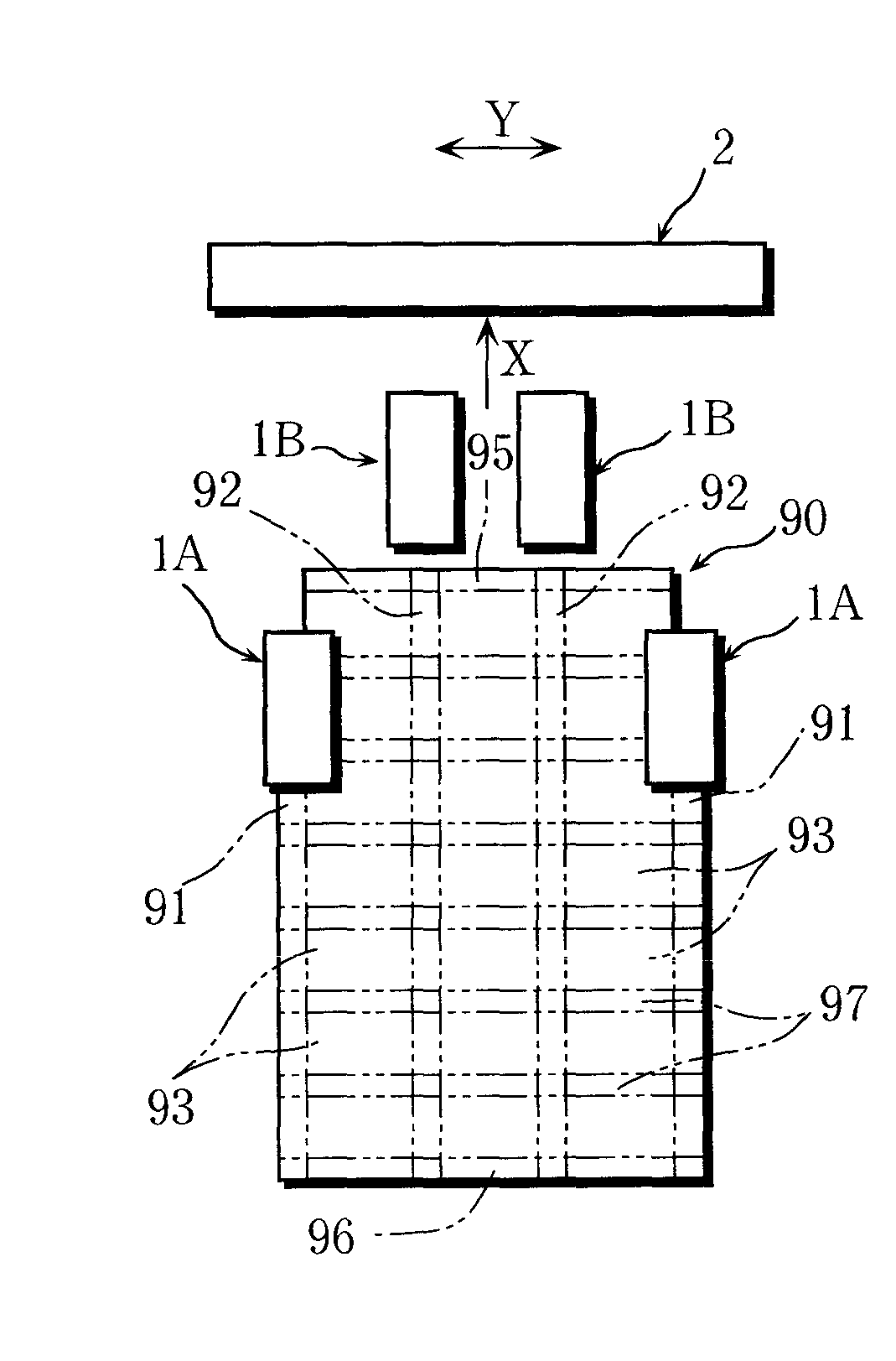

[0022] An example of a cutting plan for paper 90 is taken in the figure 2 shown for ease of interpretation. The sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com