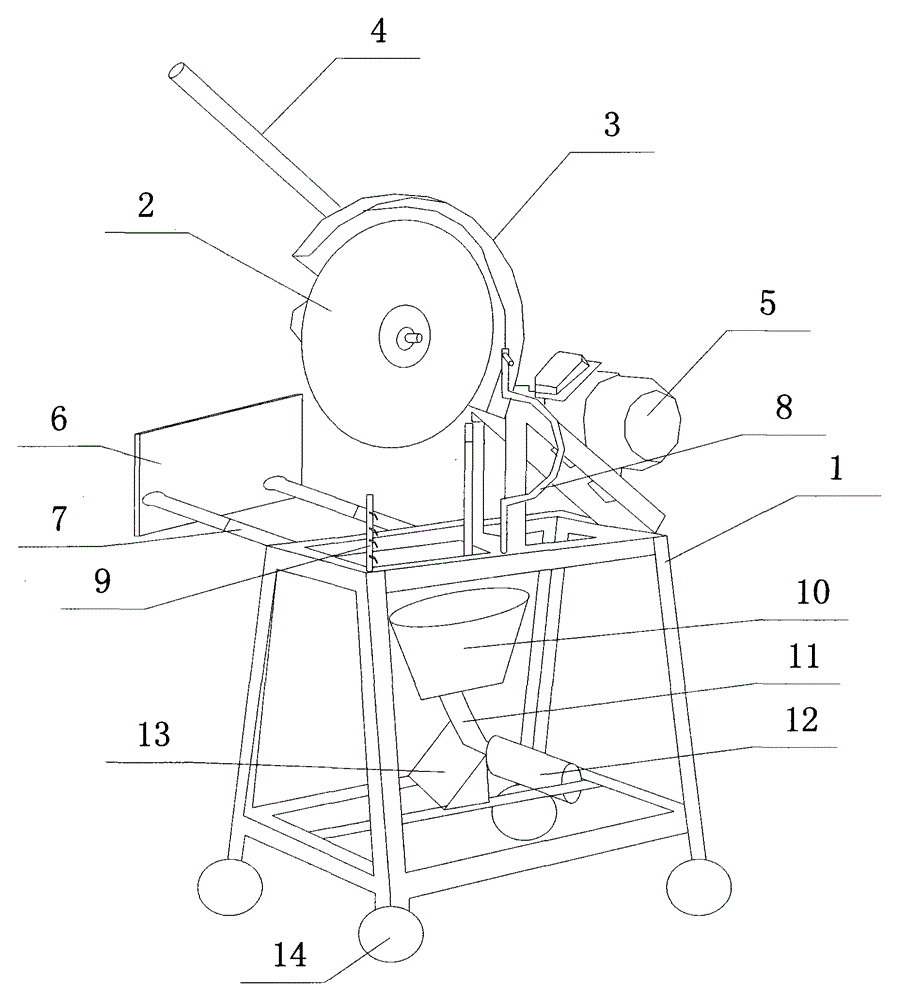

Raw Bamboo Saw Machine

A technology of sawing machine and frame, which is applied in the field of bamboo product production equipment, can solve the problems of wasting manpower, trouble, and generating a lot of debris, etc., and achieves the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Take 10 raw bamboos with different lengths, then place 10 raw bamboos on the rack at the same time, then use a ruler to measure the size to be sawed off, and use the telescopic rod to adjust the position of the baffle after measuring the size, and fix the baffle The position of the board, put the front end of the bamboo against the baffle, and then turn on the power, the knife body rotates at a high speed under the drive of the first motor, and then use the handle to move the knife body down to cut the original bamboo, which will produce a lot of debris Chips, the suction cup at the lower part of the frame will suck the chips into the chip dustbin under the drive of the second motor, and then perform the next round of cutting after cutting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com