Auxiliary paper collecting and lifting device and working method for same

A technology of lifting device and working method, which is applied in the direction of stack receiving device, transportation and packaging, thin material processing, etc., can solve the problems affecting production efficiency, etc., and achieve the effects of simple structure, increased paper delivery space, and convenient manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

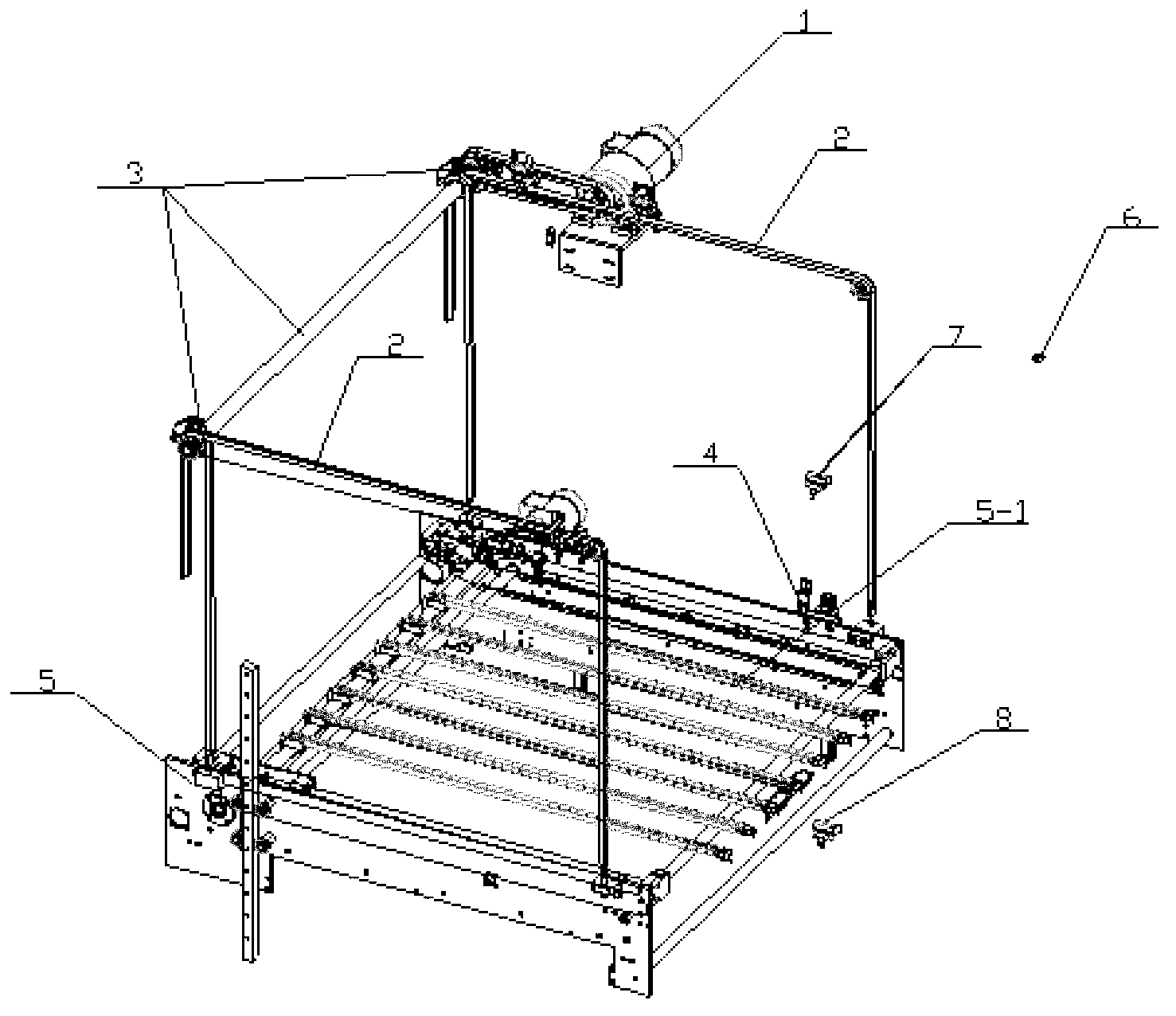

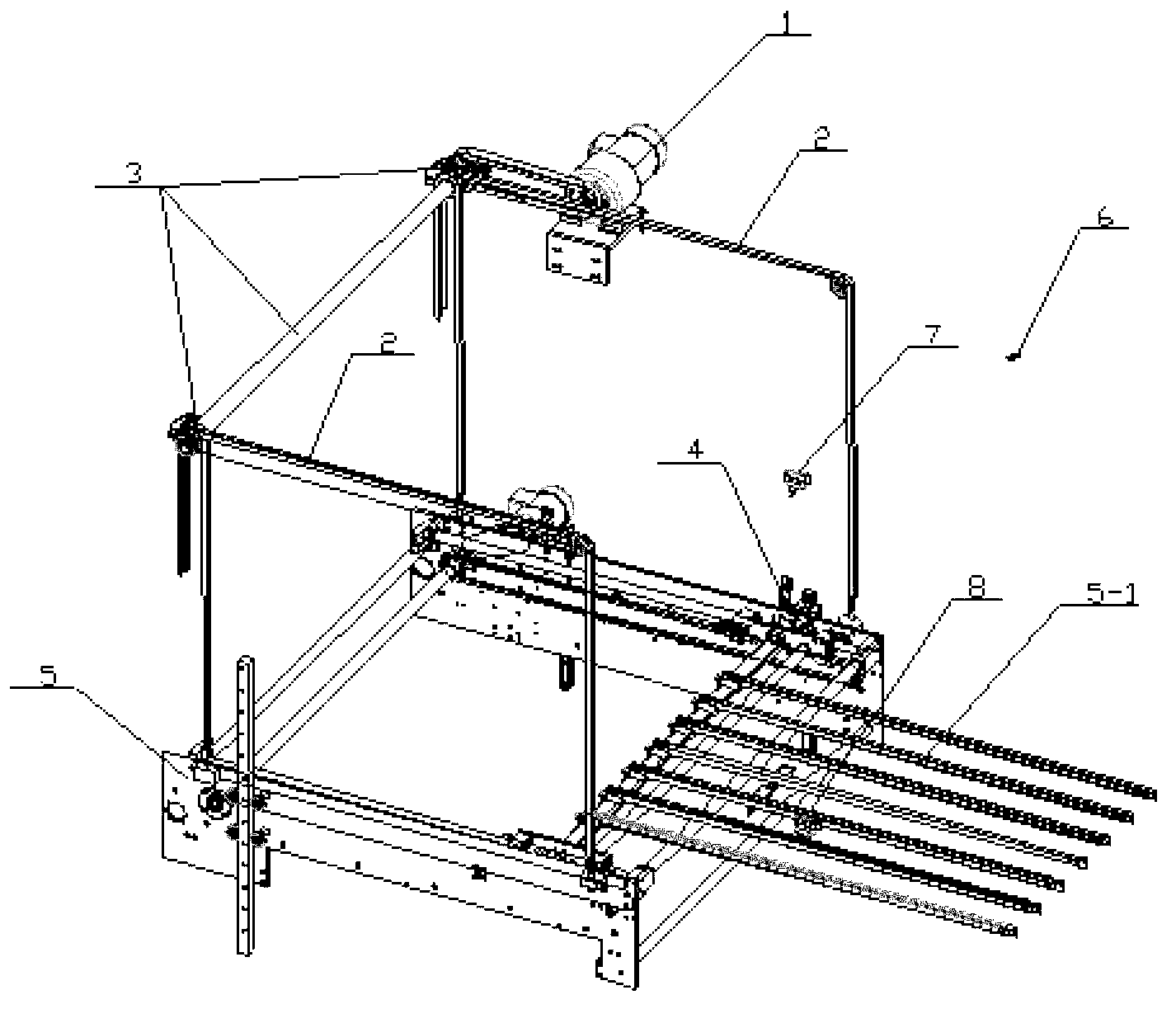

[0024] Embodiment: a kind of auxiliary delivery lifting device (see figure 1 , figure 2 ), which is characterized in that it is composed of a motor 1, a chain 2, a chain transmission device 3, a limit device and an auxiliary delivery device 5; the motor 1 is connected to the chain transmission device 3; the chain transmission device 3 is connected to the chain 2 ; The chain 2 is connected with the auxiliary paper delivery device 5; the limit device is installed at the limit position where the auxiliary paper delivery device 5 moves up and down.

[0025] The limit device is composed of an upper limit switch 7 and a lower limit switch 8; the upper limit switch 7 is located on the upper limit surface of the auxiliary paper delivery device 5 rising, and is fixedly installed on a wallboard or a frame; the lower limit switch 8 Located on the lower limit surface where the auxiliary delivery device 5 descends, it is fixedly installed on a wallboard or a frame; both the upper limit s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com