Oil displacement composition, multi-component thermal fluid oil displacement composition containing same, and displacement method

A multi-component thermal fluid and composition technology, which is applied in the direction of drilling composition, production fluid, chemical instruments and methods, etc., can solve the problem of being unable to become an effective replacement technology for Type II and Type III heavy oil, and cannot be effectively transferred to steam flooding and other problems, to achieve the effects of low production cost, suppression of steam overburden phenomenon, and increase of displacement pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides an oil displacement composition, which includes 15 tons of ammonium bicarbonate, 5 tons of GFPJ-10 high temperature foam agent, 1 ton of high temperature oil displacement agent and 35 tons of water, wherein, the high temperature oil displacement agent is petroleum ring A mixture formed by mixing alkanoic acid diethanolamide and sodium carbonate at a mass ratio of 1:3. The preparation method of the oil-displacing composition comprises the following steps: adding 40°C hot water into ammonium bicarbonate, stirring evenly, adding high-temperature foaming agent and high-temperature oil-displacing agent, and then stirring evenly, that is, the preparation of the present embodiment Oil displacement composition.

[0029] This embodiment also provides a multi-element thermal fluid displacement method, which includes the following steps:

[0030] The above-mentioned oil displacement composition just prepared was transported to Well Du 813-45-91 in Liaohe ...

Embodiment 2

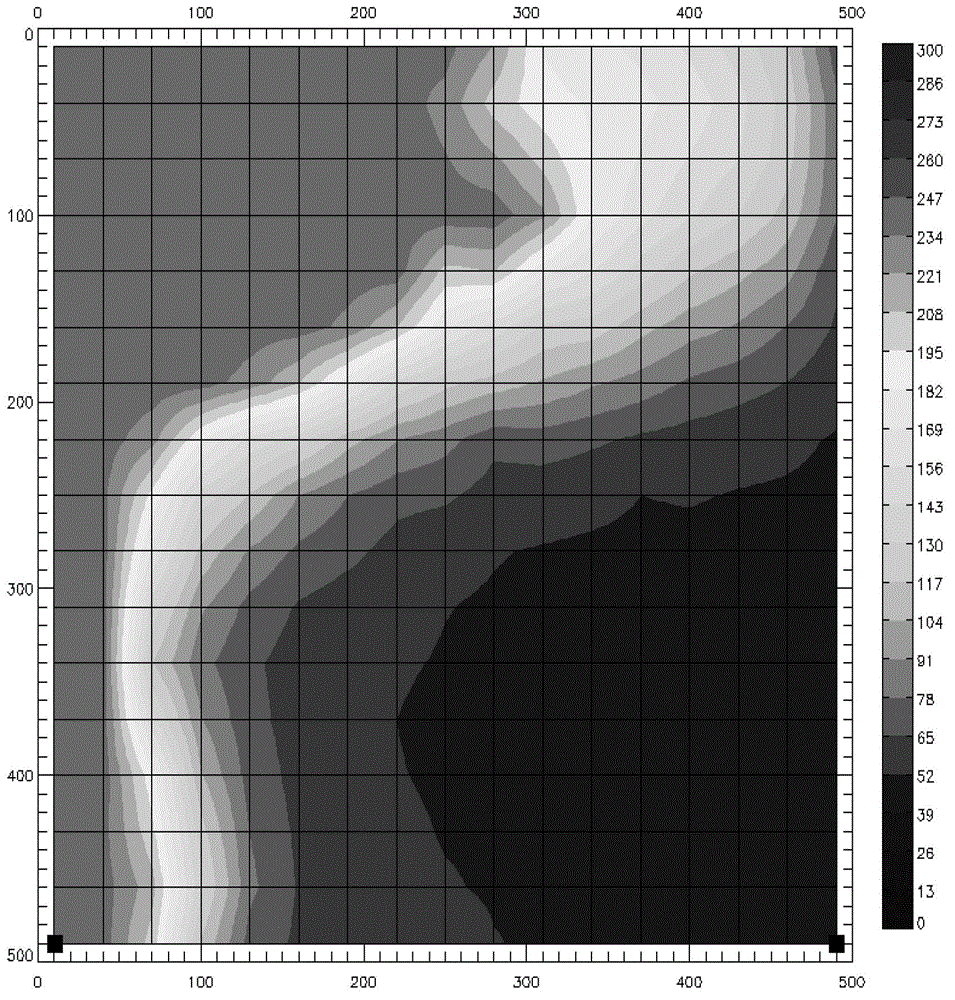

[0036] This example provides a comparison experiment of conventional steam flooding and the multi-element thermal fluid flooding composition of the present invention in a two-dimensional physical simulation model.

[0037] In this flooding experiment, a two-dimensional physical simulation model of 50cm×50cm×4cm was used, and quartz sands of different meshes were loaded into it. The thickness and permeability of the oil layer are consistent with the actual oil layer in Block Jin 45, but the influence of interlayers is ignored. That is to say, only 4 oil layers are filled in the longitudinal direction of the oil layer, the thicknesses are 4.4cm, 7.1cm, 6.5cm, 5.7cm; the permeability is 1.4μm 2 , 2.8 μm 2 , 1.3 μm 2 , 1.7 μm 2 ; The porosity is 22.8%, 26.7%, 23.4%, 24.1%; the rhythm is similar to the actual oil layer; the high permeability layer is located in the upper part of the production layer; the simulated reservoir pressure is 4.0MPa, and the simulated reservoir tempera...

Embodiment 3

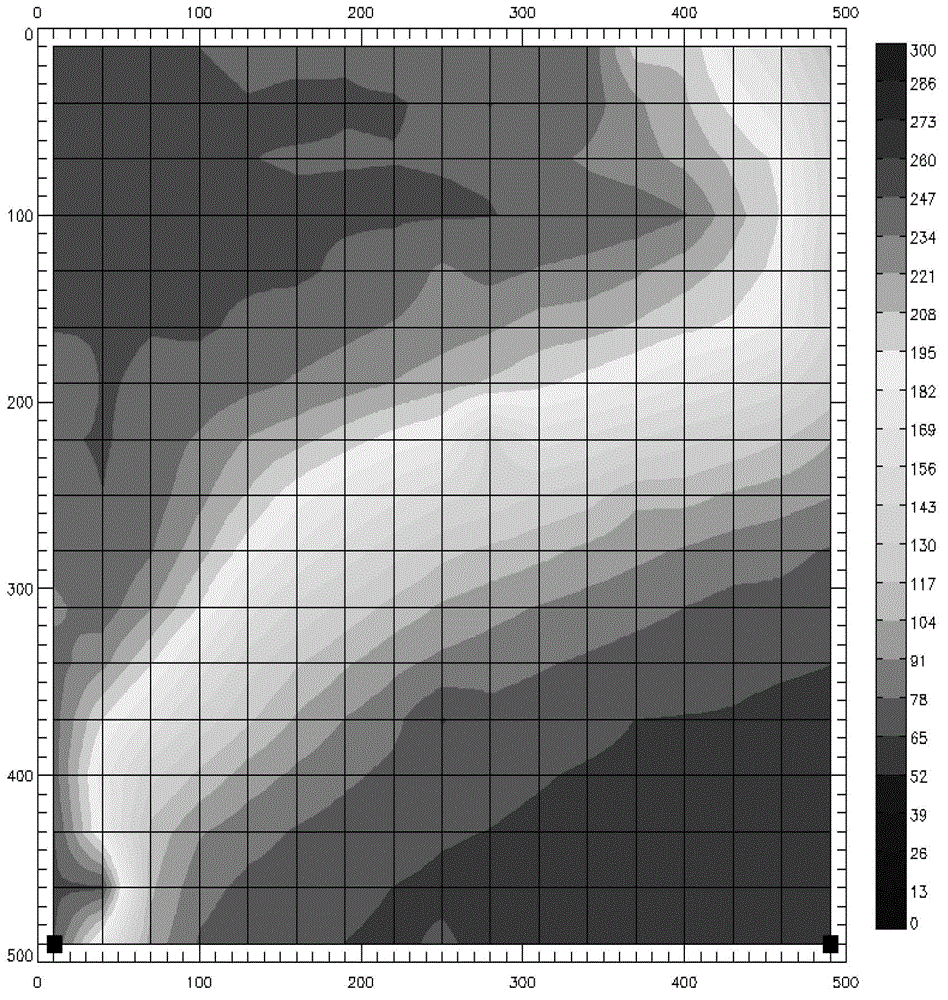

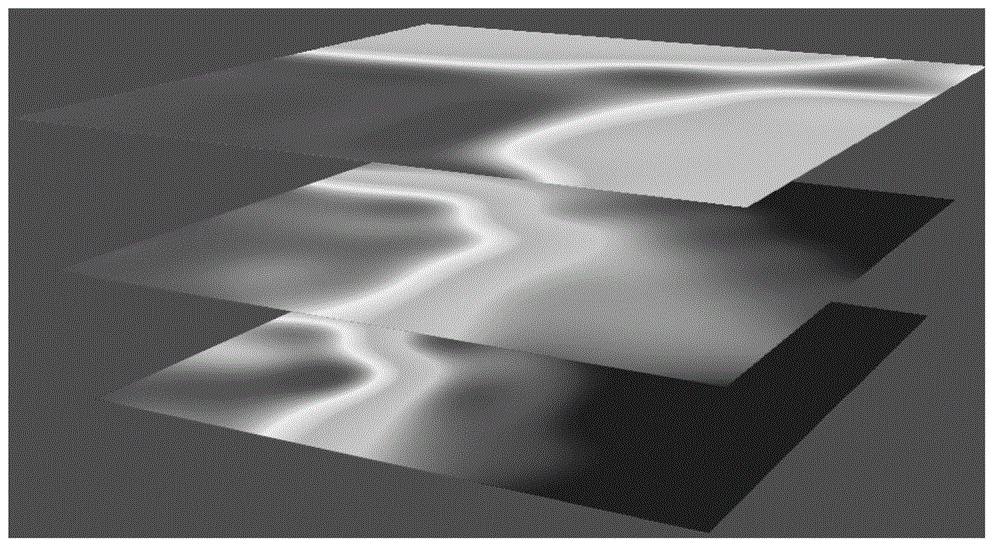

[0059] This example provides a comparison experiment of conventional steam flooding and the multi-component thermal fluid flooding composition of the present invention in a high-temperature and high-pressure steam injection three-dimensional physical simulation experimental device.

[0060] In this displacement experiment, a high-temperature and high-pressure steam injection three-dimensional physical simulation experiment device with an injection-production well spacing of 57cm×40cm was used, and quartz sands of different meshes were placed in it to form thicknesses of 2.5cm, 0.8cm, and 1.5cm. Heterogeneous reservoirs of 466mD, 170mD, and 322mD respectively, with an average reservoir porosity of 38% and an average initial oil saturation of 0.85; a 1 / 4 inverse nine-point area well pattern was selected, and a total of Set up 3 vertical production wells and 1 vertical well injection well; the lower 2 / 3 of the oil layer section of the injection well is shot, and the oil layer sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com