A method for smelting molybdenum-containing stainless steel

The technology of stainless steel and molybdenum oxide powder is applied in the field of directly smelting molybdenum-containing stainless steel by using molybdenum oxide powder, and smelting molybdenum-containing stainless steel, which can solve the problem of high cost and achieve the effects of reducing raw materials, reducing production cost and simplifying production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

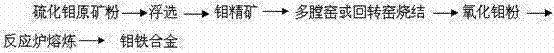

Method used

Image

Examples

Embodiment 1

[0062] Example 1: Method for Smelting Molybdenum-Containing Stainless Steel by Blast Furnace Hot Metal Injection

[0063] (1) Molybdenum oxide powder is added to the feed tank, and the pressure of the feed tank is 0.2±0.02MPa; 95% of the molybdenum oxide powder in the raw material has a particle size of less than 1mm, and the molybdenum content in the molybdenum oxide powder is 60.8%;

[0064] (2) Use high-pressure nitrogen as the carrier gas, the carrier gas pressure is 0.6±0.02MPa, and the carrier gas flow rate is 60±3Nm 3 / h, the molybdenum oxide powder is transported to the fluidized bed to realize the fluidization of the molybdenum oxide powder;

[0065] (3) Molybdenum oxide powder enters the rotor feeder, and the injection speed is controlled by the rotor feeder;

[0066] (4) Add iron

[0067] Mix the blast furnace molten iron into the injection treatment tank, the mixing amount is 68±2 tons, remove the blast furnace slag, the slag thickness is required to be ≤30mm, a...

Embodiment 2

[0084] Embodiment 2: Method for smelting molybdenum-containing stainless steel by injection of stainless steel mother liquor

[0085] (1) Molybdenum oxide powder is added to the feeding tank, and the pressure of the feeding tank is 0.2±0.02MPa; the particle size of 95% of the molybdenum oxide powder in the raw material is less than 1mm, and the molybdenum content in the molybdenum oxide powder is 60.2%;

[0086] (2) Use high-pressure nitrogen as the carrier gas, the carrier gas pressure is 0.6±0.02MPa, and the carrier gas flow rate is 80Nm 3 / h, the molybdenum oxide powder is transported to the fluidized bed to realize the fluidization of the molybdenum oxide powder;

[0087] (3) Molybdenum oxide powder enters the rotor feeder, and the injection speed is controlled by the rotor feeder;

[0088] (4) Pre-melt mixed with steel: The stainless steel mother liquid is smelted in an electric furnace and tapped into the ladle. The distance from the upper edge of the mouth is 12...

Embodiment 3

[0107] Embodiment 3: Method for smelting molybdenum-containing stainless steel by spraying stainless steel mother liquor

[0108] (1) Molybdenum oxide powder is added to the feed tank, and the pressure of the feed tank is 0.2±0.02MPa; the particle size of 95% of the molybdenum oxide powder in the raw material is less than 1mm, and the molybdenum content in the molybdenum oxide powder is 60.3%;

[0109] (2) Use high-pressure nitrogen as the carrier gas, the carrier gas pressure is 0.6±0.02MPa, and the carrier gas flow rate is 80Nm 3 / h, the molybdenum oxide powder is transported to the fluidized bed to realize the fluidization of the molybdenum oxide powder;

[0110] (3) Molybdenum oxide powder enters the rotor feeder, and the injection speed is controlled by the rotor feeder;

[0111] (4) Pre-melt mixed with steel: The stainless steel mother liquor is smelted in an electric furnace and tapped into the ladle, with a steel output of 165±3 tons, and the electric furnace sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com