Bond-type anchorage for FRP (Fiber Reinforced Plastic) rib and implementation method thereof

A bonded anchorage technology, applied in the direction of structural elements, building materials, building components, etc., can solve the problems of large anchorage length, damage of tendons, and stress concentration in the hoop direction, so as to ensure the safety of implementation, The effect of low material requirement and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

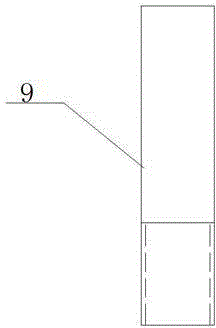

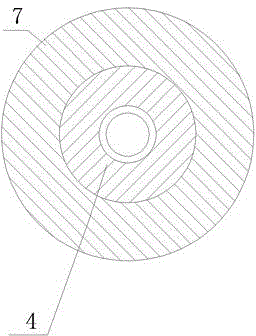

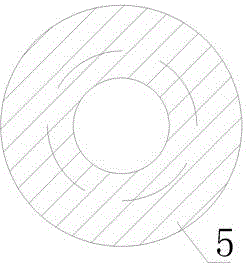

[0030] When the number of the sliding anchor tube 4 and the number of the fixed anchor tube 5 is one, the implementation method of the present invention is as follows.

[0031] (1) Connect the fixed anchor tube 5 and the nut 7 through the first thread 6-1, then block the FRP reinforcement from the first end 1-1, slide the anchor tube 4, and plug the second end 1-2, The nut 7, the fixed anchor tube 5, and the third end block 1-3 are sequentially passed through.

[0032] (2) Fix the first end plug 1-1 and the second end plug 1-2 at both ends of the sliding anchor cylinder 4 .

[0033] (3) Connect the sliding anchor tube 4 and the nut 7 through the first thread 6-1, so that the sliding anchor tube 4 and the fixed anchor tube 5 are fixedly connected through the nut 7, and the second end plug 1-2 is connected with the fixed One end of the anchor tube 5 matches, and the FRP reinforcement is positioned.

[0034] (4), fix the third end plug 1-3 of anchor tube 5.

[0035] (5) Use pr...

Embodiment 2

[0039] When the number of sliding anchor cylinders is two and the number of fixed anchor cylinders 5 is one, the number of nuts 7 increases accordingly, and the implementation method of the present invention is as follows.

[0040] (1) Connect the fixed anchor tube 5 and the nut 7 through the first thread 6-1, then block the FRP reinforcement from the first end 1-1, slide the anchor tube 4, and plug the second end 1-2, The nut 7, the sliding anchor tube 4, the second end plug 1-2, the nut 7, the fixed anchor tube 5, and the third end plug 1-3 are sequentially passed through.

[0041] All the other are consistent with embodiment 1.

[0042] Or, (1) Connect the fixed anchor tube 5 and the nut 7 through the first thread 6-1, block the FRP reinforcement from the first end 1-1, slide the anchor tube 4, and block the second end 1-2, The nut 7, the fixed anchor tube 5, the second end plug 1-2, the nut 7, the sliding anchor tube 4, and the third end plug 1-3 are sequentially passed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com