Simple, convenient and efficient detachable static seal structure

A static sealing and high-efficiency technology, applied to engine sealing, engine components, mechanical equipment, etc., can solve problems such as inconvenient maintenance, cumbersome installation, and bulky structure, and achieve the effects of convenient maintenance, reduced workload, and increased construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

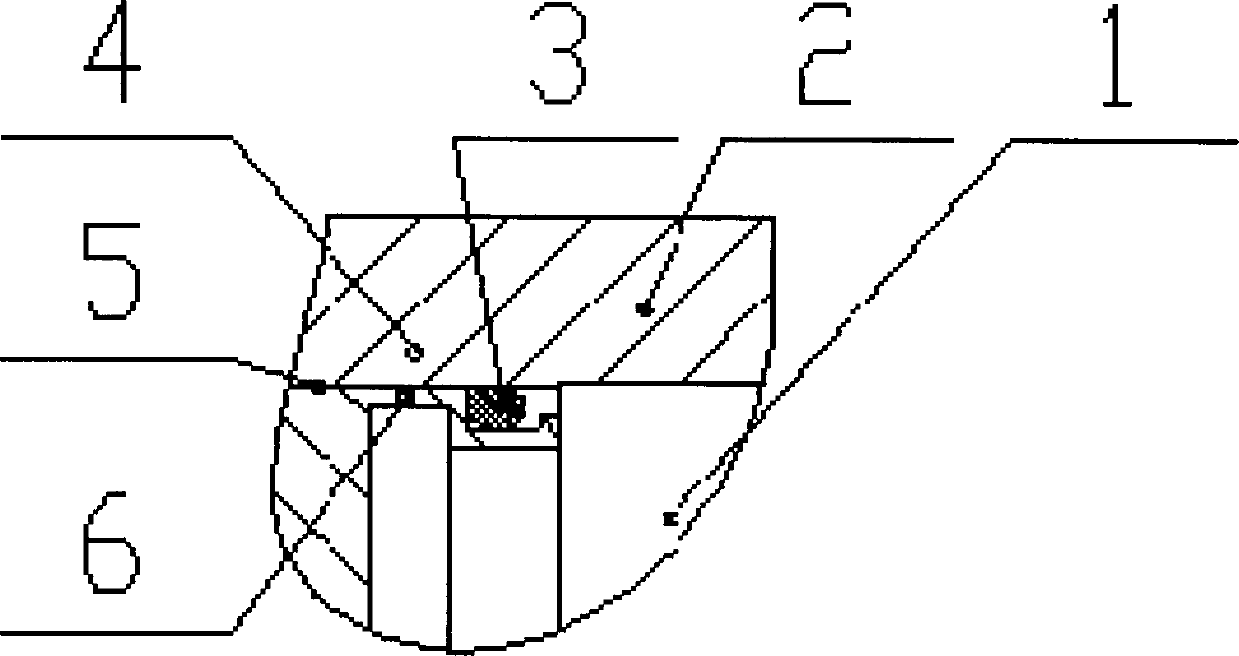

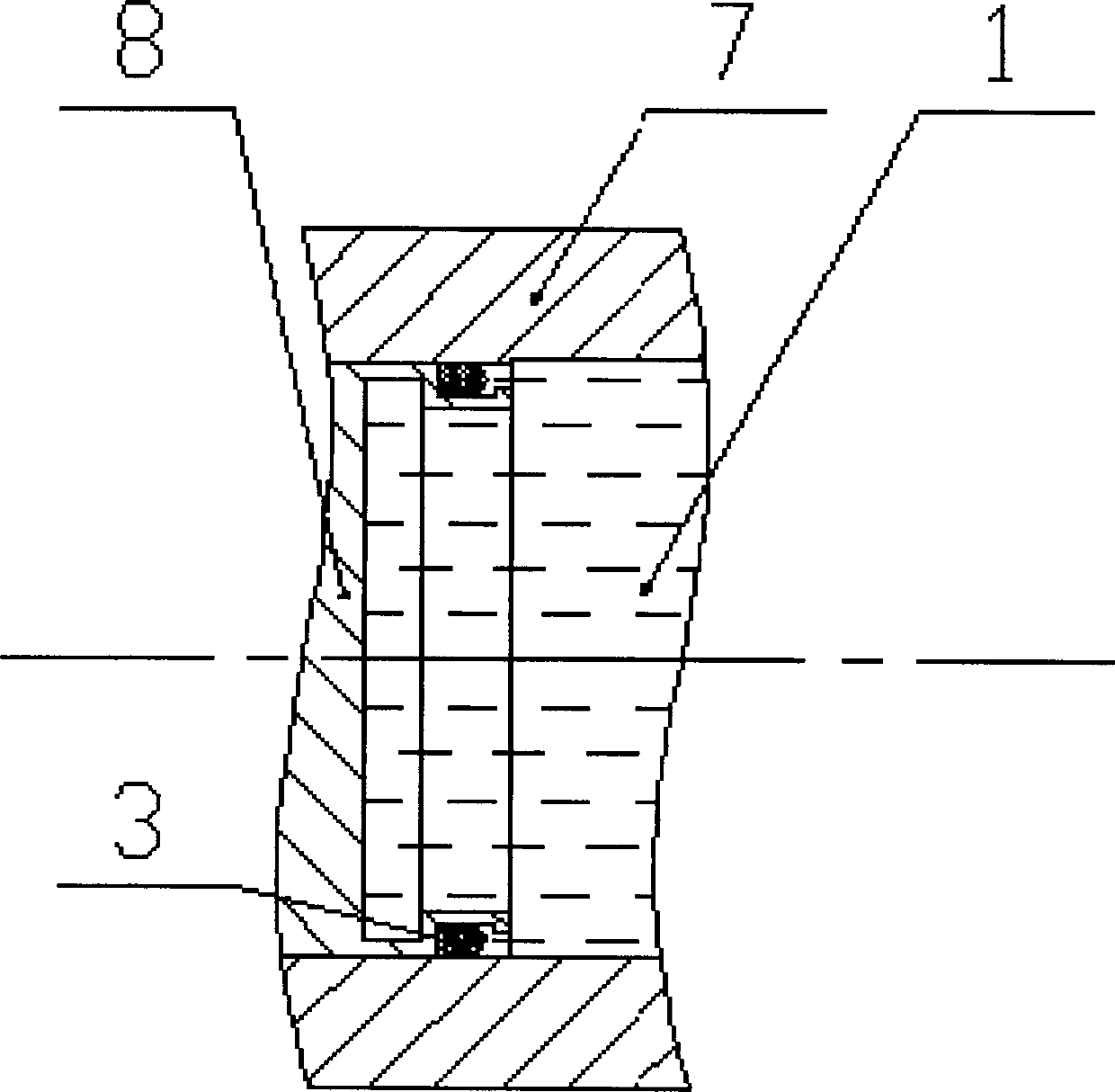

Embodiment 1

[0020] Example 1, such as figure 2 As shown in the figure, 1. The medium to be sealed, 3. The sealing element, 7. The pressure-bearing shell, and 8. The sealing end cover.

[0021] The sealing end cover 8 is provided with a large inner diameter and thin-walled area on the left side of the sealing element 3. This area is deformed and adheres to the pressure-bearing shell 7 after the pressure difference between the sealed medium 1 and the outside world increases, eliminating the gap reserved during the initial installation between the two. gap, to avoid sealing failure caused by the sealing element 3 being extruded from this gap under high pressure difference.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com